To properly clean the quartz optical windows of an electrolytic cell, you must use a dedicated optical lens cleaning solution and a soft, non-abrasive optical cleaning cloth. This specific approach is crucial for preventing scratches that permanently degrade the window's surface and compromise the accuracy of your optical measurements.

The core challenge is not just cleaning the windows, but integrating this delicate task into a robust maintenance protocol for the entire electrolytic cell. The key is to use gentle, specialized methods for the optics while employing a more rigorous multi-step process for the cell body to ensure no residues interfere with future experiments.

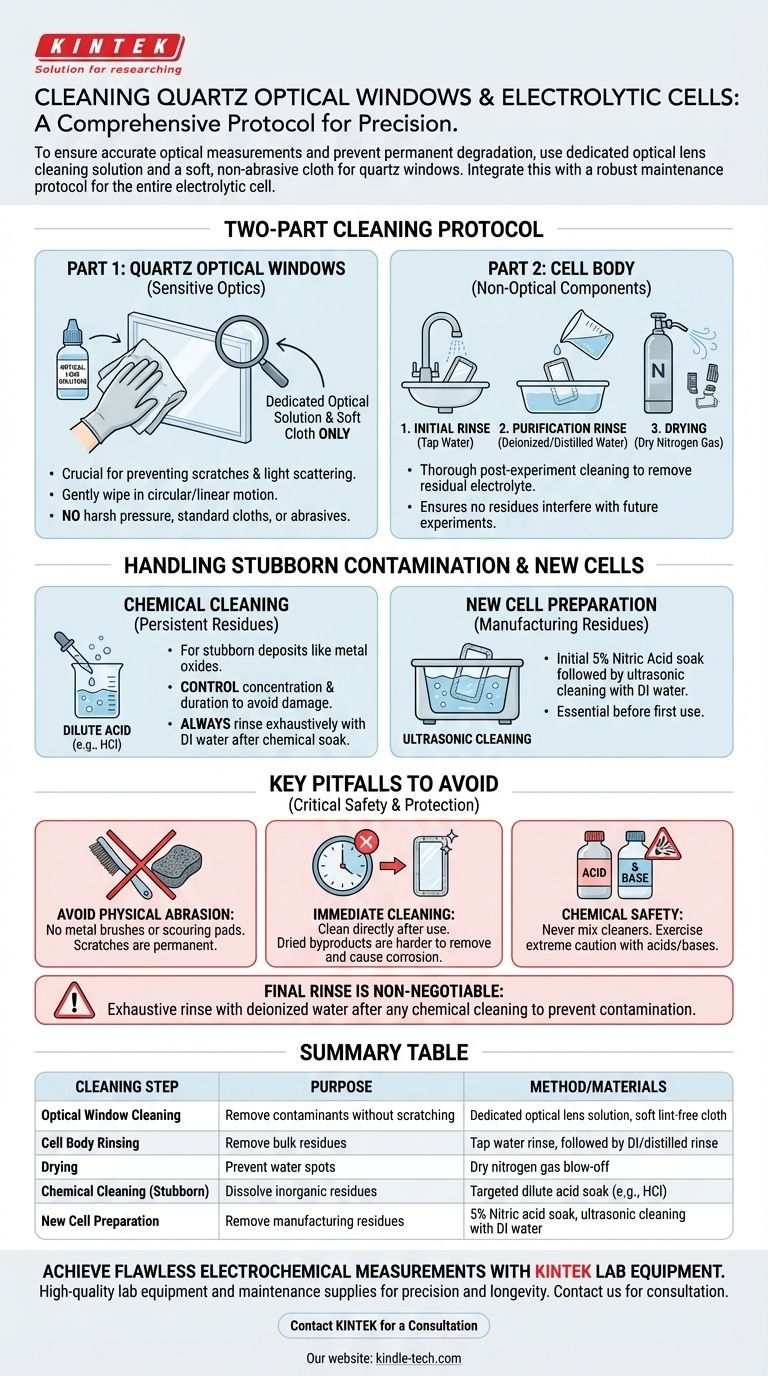

The Two-Part Cleaning Protocol: Optics vs. Cell Body

Effective maintenance requires treating the optical windows and the cell body as two distinct components with different cleaning needs.

Cleaning the Quartz Optical Windows

The windows are the most sensitive part of your setup. Their purpose is to provide a perfectly clear path for light, and any surface imperfection can scatter light and introduce errors.

Apply a small amount of dedicated optical lens cleaning solution to a lint-free, soft optical cloth. Gently wipe the window surface in a circular or linear motion. Never apply harsh pressure or use standard cloths, paper towels, or abrasive materials.

General Cleaning for the Cell Body

For the non-optical parts of the cell, a more thorough process is required immediately after each experiment to remove residual electrolyte and reaction products.

- Initial Rinse: Begin by rinsing all parts with tap water to remove the bulk of any loose material.

- Purification Rinse: Follow up with multiple, thorough rinses using deionized (DI) or distilled water. This step is critical for removing ionic impurities.

- Drying: Dry the cell components completely, preferably by blowing with dry nitrogen gas. This prevents water spots from forming, which can leave behind residues.

Handling Stubborn Contamination

Simple rinsing is not always sufficient. Different situations call for more aggressive, targeted cleaning methods.

Chemical Cleaning for Persistent Residues

When you encounter stubborn deposits, such as metal oxides or dried-on products, chemical cleaning may be necessary.

The choice of chemical depends entirely on the nature of the contaminant. For example, a dilute acid like hydrochloric acid (HCl) can be effective at removing rust or other metal oxides.

Crucially, you must control the concentration and duration of the chemical soak to avoid corroding or damaging the cell material.

Special Protocol for New Cells

A brand-new cell often has residual contaminants from the manufacturing process that must be removed before its first use.

A common protocol is to first soak the cell body in a 5% nitric acid (HNO₃) solution for approximately two hours. Follow this by cleaning it with deionized water in an ultrasonic bath several times before drying.

Understanding the Key Pitfalls

Mistakes during cleaning can permanently damage your equipment or compromise your data. Adhering to these principles is non-negotiable.

Avoid Physical Abrasion at All Costs

Never use metal brushes, scouring pads, or any abrasive tool on any part of the cell, especially the quartz windows. Scratches are permanent and will ruin the optical quality of the window.

The Importance of Immediate Cleaning

Clean the cell and its components immediately after each experiment. Allowing electrolytes and reaction byproducts to dry makes them significantly harder to remove and increases the risk of corrosion and permanent staining.

Chemical Safety is Paramount

When using chemical cleaners, exercise extreme caution. Never mix different cleaning agents, especially acids and bases, as this can trigger a dangerous and exothermic reaction.

The Final Rinse is Non-Negotiable

After any chemical cleaning, the cell must be rinsed exhaustively with deionized water. Any residual cleaning agent left in the cell will become a contaminant in your next experiment, invalidating your results.

Making the Right Choice for Your Goal

Your cleaning strategy should adapt to the specific situation.

- For routine post-experiment cleaning: Your default should be an immediate rinse with tap water followed by multiple rinses with deionized water and drying with nitrogen.

- For stubborn inorganic deposits: Use a targeted chemical soak (e.g., dilute acid), carefully controlling time and concentration, followed by an exhaustive DI water rinse.

- For preparing a brand-new cell: Perform an initial acid soak and ultrasonic cleaning to remove any manufacturing residues before its first use.

- For maintaining optical clarity: Always clean the quartz windows separately using only dedicated optical lens cleaner and a proper soft cloth.

A disciplined and appropriate cleaning regimen is the foundation of reliable and repeatable spectroelectrochemical measurements.

Summary Table:

| Cleaning Step | Purpose | Method/Materials |

|---|---|---|

| Optical Window Cleaning | Remove contaminants without scratching | Dedicated optical lens solution, soft lint-free cloth |

| Cell Body Rinsing | Remove bulk electrolyte/residues | Tap water rinse, followed by DI/distilled water rinse |

| Drying | Prevent water spots and residues | Dry nitrogen gas blow-off |

| Chemical Cleaning (Stubborn Deposits) | Dissolve persistent inorganic residues | Targeted dilute acid soak (e.g., HCl), controlled time |

| New Cell Preparation | Remove manufacturing residues | 5% Nitric acid soak, ultrasonic cleaning with DI water |

Achieve Flawless Electrochemical Measurements with KINTEK Lab Equipment

Proper cleaning is essential for reliable data, but it starts with having the right equipment. KINTEK specializes in high-quality lab equipment and consumables, including electrolytic cells and maintenance supplies designed for precision and longevity.

Let our experts help you select the ideal equipment and establish robust maintenance protocols for your laboratory. Contact us today to ensure your experiments are built on a foundation of reliability and accuracy.

Contact KINTEK for a Consultation

Visual Guide

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Electrolytic Electrochemical Cell for Coating Evaluation

- Optical Window Glass Substrate Wafer CaF2 Substrate Window Lens

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- CVD Diamond Optical Windows for Lab Applications

People Also Ask

- Does quartz have a high melting point? Discover Its Superior High-Temperature Performance

- What is the high temperature of quartz? Key Thresholds for Crystalline vs. Fused Silica

- What is high temperature quartz? A Guide to Unmatched Thermal Stability & Purity

- What is the temperature range of quartz glass? Master Its Thermal Limits for Demanding Applications

- How does quartz differ from glass? A Guide to Material Selection for Performance