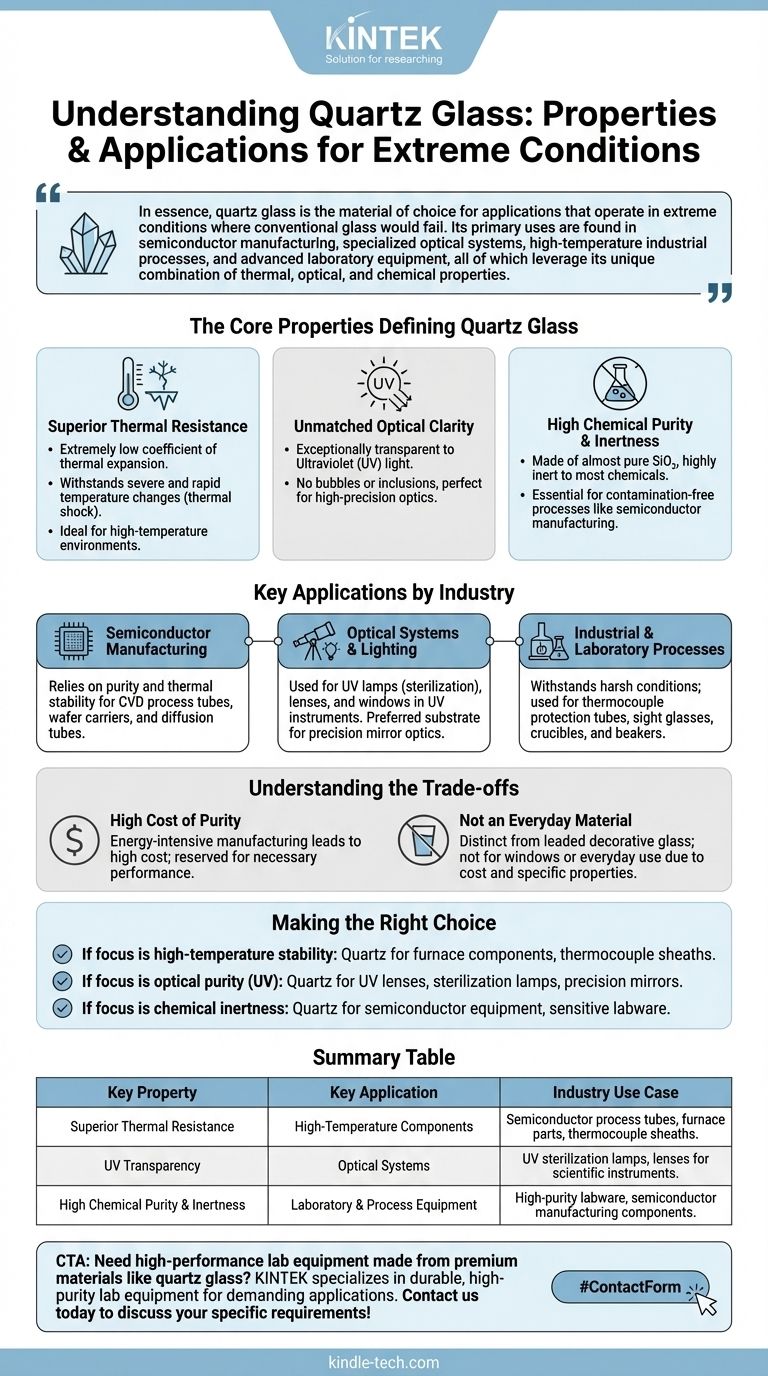

In essence, quartz glass is the material of choice for applications that operate in extreme conditions where conventional glass would fail. Its primary uses are found in semiconductor manufacturing, specialized optical systems, high-temperature industrial processes, and advanced laboratory equipment, all of which leverage its unique combination of thermal, optical, and chemical properties.

The value of quartz glass comes not from being a better version of everyday glass, but from its fundamental purity. Composed of nearly 100% silicon dioxide (SiO₂), it possesses superior thermal shock resistance, unmatched transparency to ultraviolet light, and high chemical inertness, making it indispensable for demanding technical and scientific tasks.

The Core Properties Defining Quartz Glass

To understand the applications of quartz glass, you must first understand the properties that set it apart. Unlike common soda-lime glass (used for windows and bottles), quartz glass is a high-purity material engineered for performance, not commodity use.

Superior Thermal Resistance

Quartz glass has an extremely low coefficient of thermal expansion. This means it changes very little in size when heated or cooled, allowing it to withstand severe and rapid temperature changes (thermal shock) without cracking.

A standard glass container would shatter if taken from a flame and plunged into ice water, but quartz glass can handle this transition easily. This makes it ideal for equipment used in high-temperature environments.

Unmatched Optical Clarity (Especially in UV)

While most glass blocks ultraviolet (UV) light, fused quartz is exceptionally transparent to it. This unique optical property is critical for devices that use or analyze the UV spectrum.

Its purity also ensures there are no bubbles or inclusions that would distort light, making it a prime material for high-precision optics.

High Chemical Purity and Inertness

Because it is made of almost pure SiO₂, quartz glass is highly inert and does not react with most acids, bases, or other chemicals. This purity is vital in applications where any contamination, even at a microscopic level, could ruin a process.

This is particularly true in semiconductor manufacturing and trace-element analysis, where maintaining a pristine environment is non-negotiable.

Key Applications by Industry

The unique properties of quartz glass translate directly into its use across several high-tech sectors. Each application leverages one or more of its core strengths.

Semiconductor Manufacturing

The semiconductor industry relies heavily on quartz glass for its combination of purity and thermal stability. Any contamination can render a batch of microchips useless.

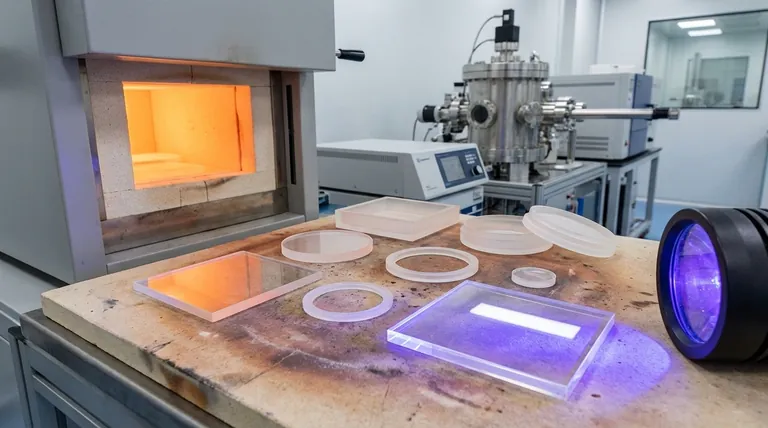

Common components include process tubes for Chemical Vapor Deposition (CVD), wafer carriers (known as boats), and diffusion tubes, all of which operate at extremely high temperatures in a chemically sensitive environment.

Optical Systems and Lighting

Due to its UV transparency, quartz glass is the primary material for UV lamps used in sterilization, as well as for lenses and windows in scientific instruments that operate in the ultraviolet spectrum.

Its thermal stability and low expansion also make it the preferred substrate for precision mirror optics in telescopes and lasers, where even minute distortion from heat would compromise accuracy.

Industrial and Laboratory Processes

In industrial settings, quartz glass is used for components that need to withstand harsh conditions, such as thermocouple protection tubes for measuring temperature in molten metal. It is also used for sight glasses and level gauges in high-temperature or corrosive chemical reactors.

In the laboratory, its chemical inertness and ability to be sterilized make it the material of choice for high-purity crucibles, beakers, and other apparatuses.

Understanding the Trade-offs

While its performance is exceptional, quartz glass is not a universal solution. Understanding its limitations is key to appreciating its specific role.

The High Cost of Purity

Manufacturing quartz glass involves melting highly pure, naturally occurring quartz crystals at extreme temperatures. This process is far more energy-intensive and expensive than producing standard glass.

This cost is the primary reason it is reserved for applications where its specific properties are a technical necessity.

Not an Everyday Material

The term "crystal" can be misleading. Decorative glassware, such as "Swarovski crystal" or "cut glass," is typically leaded glass, which is prized for its high refractive index that creates sparkle.

Quartz glass is not used for everyday items like drinking glasses or windows. Its advanced properties are unnecessary for these roles, and its cost would be prohibitive.

Making the Right Choice for Your Goal

Selecting quartz glass is a decision driven entirely by the demands of the application. Its use is a solution to a problem that standard materials cannot solve.

- If your primary focus is high-temperature stability: Quartz glass is the definitive choice for furnace components, thermocouple sheaths, and any application requiring resistance to extreme thermal shock.

- If your primary focus is optical purity, especially in the UV spectrum: It is the only practical material for UV transmission lenses, sterilization lamps, and high-precision mirror substrates.

- If your primary focus is chemical inertness and absolute purity: Quartz glass is essential for semiconductor processing equipment and labware used in sensitive chemical analysis.

Ultimately, quartz glass is a problem-solving material, specified by engineers and scientists when performance in extreme environments is the only acceptable outcome.

Summary Table:

| Key Property | Key Application | Industry Use Case |

|---|---|---|

| Superior Thermal Resistance | High-Temperature Components | Semiconductor process tubes, furnace parts, thermocouple sheaths |

| UV Transparency | Optical Systems | UV sterilization lamps, lenses for scientific instruments |

| High Chemical Purity & Inertness | Laboratory & Process Equipment | High-purity labware, semiconductor manufacturing components |

Need high-performance lab equipment made from premium materials like quartz glass? KINTEK specializes in providing durable, high-purity lab equipment and consumables designed for demanding applications in semiconductor manufacturing, advanced research, and industrial processes. Let our experts help you select the right components for your extreme environment needs. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- Does quartz have a high melting point? Discover Its Superior High-Temperature Performance

- What is optical quartz? The Ultimate Material for UV and High-Temp Optics

- What is high temperature quartz? A Guide to Unmatched Thermal Stability & Purity

- What is the temperature range of quartz glass? Master Its Thermal Limits for Demanding Applications

- What are the thermal properties of quartz? Unlocking Extreme Temperature Stability for Your Lab