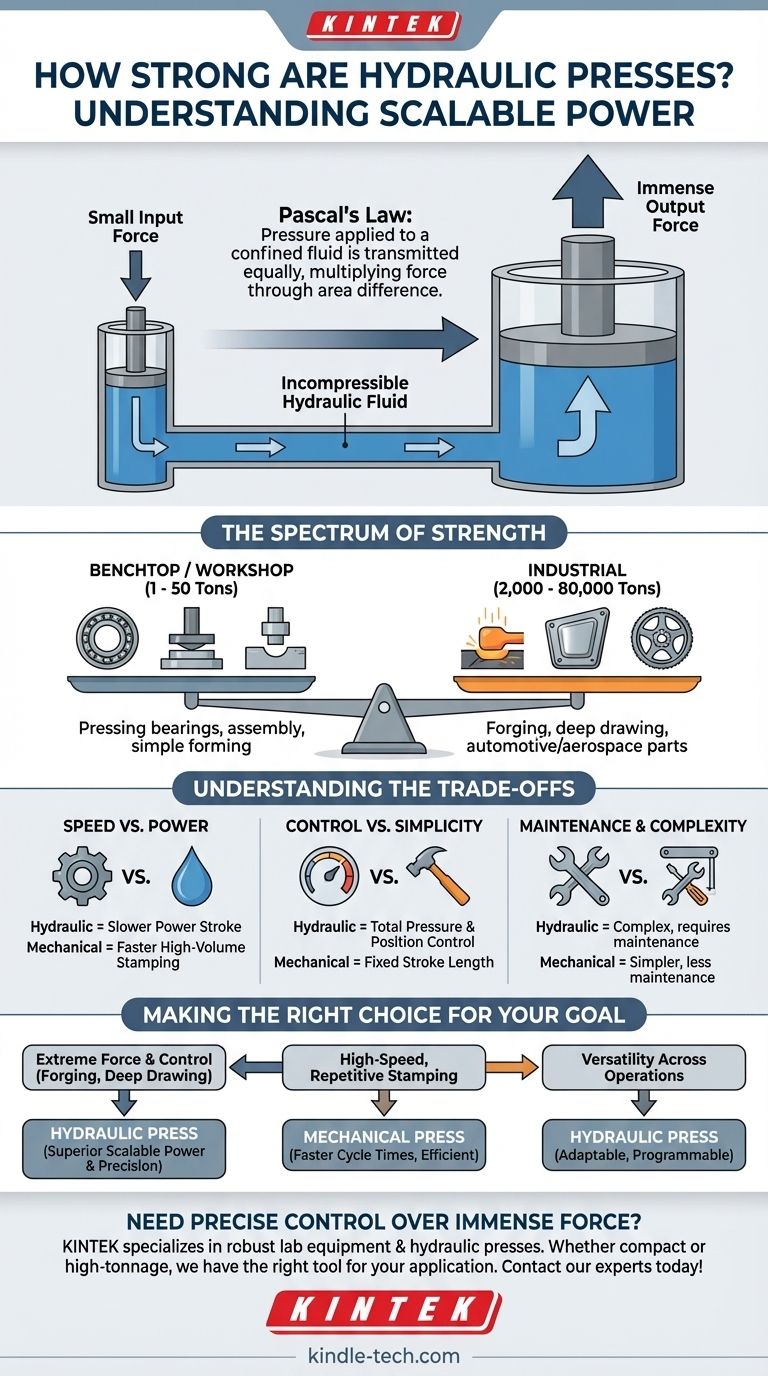

The strength of a hydraulic press is fundamentally scalable, ranging from small workshop units generating a few tons of force to colossal industrial machines capable of exerting tens of thousands of tons. This immense power isn't derived from complex gearing or motors, but from a straightforward principle of fluid dynamics known as Pascal's Law.

A hydraulic press's strength is not a single, fixed value. It is the practical application of force multiplication, where a small initial force is amplified into an immense output by pressurizing a confined fluid, limited only by the system's structural and hydraulic capacity.

The Principle Behind the Power: Pascal's Law

The incredible force of a hydraulic press comes from a simple, elegant principle discovered in the 17th century. Understanding this concept is key to understanding the machine's capabilities.

A Contained, Incompressible Fluid

At the heart of the system is a hydraulic fluid, typically oil. This fluid is incompressible, meaning its volume does not noticeably decrease when pressure is applied.

Force Multiplication in Action

Pascal's Law states that when pressure is applied to a confined fluid, that pressure is transmitted equally and undiminished to every portion of the fluid and the walls of the container.

The Area Advantage

Imagine two connected cylinders, one with a small piston (the input) and one with a much larger piston (the output). Pushing down on the small piston with a small force creates pressure in the fluid.

This same pressure then pushes up on the entire surface of the large piston. Because the large piston has a much greater surface area, the resulting output force is multiplied proportionally. If the output piston's area is 100 times greater than the input piston's, the output force will be 100 times greater.

What "Strength" Means in Practice

The tonnage of a press refers to the maximum force it can exert. This rating varies dramatically based on the machine's intended application.

From Benchtop to Industrial

A small benchtop press used in a workshop might be rated for 1 to 50 tons. These are used for tasks like pressing bearings, simple forming, or component assembly.

Forging and Heavy Manufacturing

Industrial presses used for automotive or aerospace applications are in a different league entirely. These machines, used for forging massive parts or deep-drawing large steel panels, can easily generate 2,000 to 80,000 tons of force.

Applications Dictate the Force

The specific operation determines the required strength.

- Blanking and Punching: May require moderate force depending on material thickness.

- Deep Drawing: Requires sustained and controlled force throughout the stroke.

- Forging: Demands the highest forces to shape solid metal billets.

Understanding the Trade-offs

While incredibly powerful, hydraulic presses are not the universal solution for every task. Their design involves specific trade-offs that are critical to understand.

Speed vs. Power

Achieving maximum force requires moving a large volume of hydraulic fluid, which can make the full power stroke slower than the rapid, fixed motion of a mechanical press. For high-volume, low-force stamping, a mechanical press is often faster.

Control vs. Simplicity

The primary advantage of a hydraulic press is its total control over pressure and stroke position. A mechanical press, by contrast, has a fixed stroke length and can only apply maximum tonnage at the very bottom of its stroke.

Maintenance and Complexity

While modern hydraulic systems are reliable, they are more complex than mechanical presses. They require careful maintenance of fluids, pumps, and seals to prevent leaks and ensure consistent performance.

Making the Right Choice for Your Goal

Selecting the right machine depends entirely on the specific industrial goal you need to achieve.

- If your primary focus is extreme force and control for tasks like forging or deep drawing: A hydraulic press is the superior choice due to its scalable power and precise command over the entire stroke.

- If your primary focus is high-speed, repetitive stamping of smaller parts: A mechanical press often provides a more efficient solution with faster cycle times.

- If your primary focus is versatility across different operations: The programmable nature of a hydraulic press makes it an adaptable tool for a wide range of forming, punching, and assembly tasks.

Ultimately, a hydraulic press is best understood as a precise instrument for applying and controlling immense, scalable force.

Summary Table:

| Press Type | Typical Force Range | Common Applications |

|---|---|---|

| Benchtop / Workshop | 1 - 50 tons | Pressing bearings, assembly, simple forming |

| Industrial | 2,000 - 80,000 tons | Forging, deep drawing, automotive/aerospace parts |

Need precise control over immense force for your lab or production line? KINTEK specializes in supplying robust lab equipment, including hydraulic presses tailored to your specific force and control requirements. Whether you need a compact benchtop model or a high-tonnage industrial solution, our expertise ensures you get the right tool for forging, forming, or material testing. Contact our experts today to discuss your application and find the perfect press for your needs!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- What are the advantages of using a hot press for Li7P2S8I0.5Cl0.5? Boost Conductivity with Precision Densification

- What is a hydraulic floor press used for? A Versatile Tool for Industrial and Lab Applications

- How does a laboratory hot press improve the microscopic structure of polymer-ceramic composite cathodes? | KINTEK

- What role does a hot press play in treating the CAL-GPE interface? Optimize Performance for Flexible Lithium Batteries