The strength of a hydraulic press is not a fixed value but a function of its design, capable of immense force multiplication. A small benchtop press might have a maximum recommended force of around 10 tons (9,500 kg), while large industrial models used for forging and manufacturing can generate forces exceeding 50,000 tons. The power comes from a core scientific principle, not brute mechanical size.

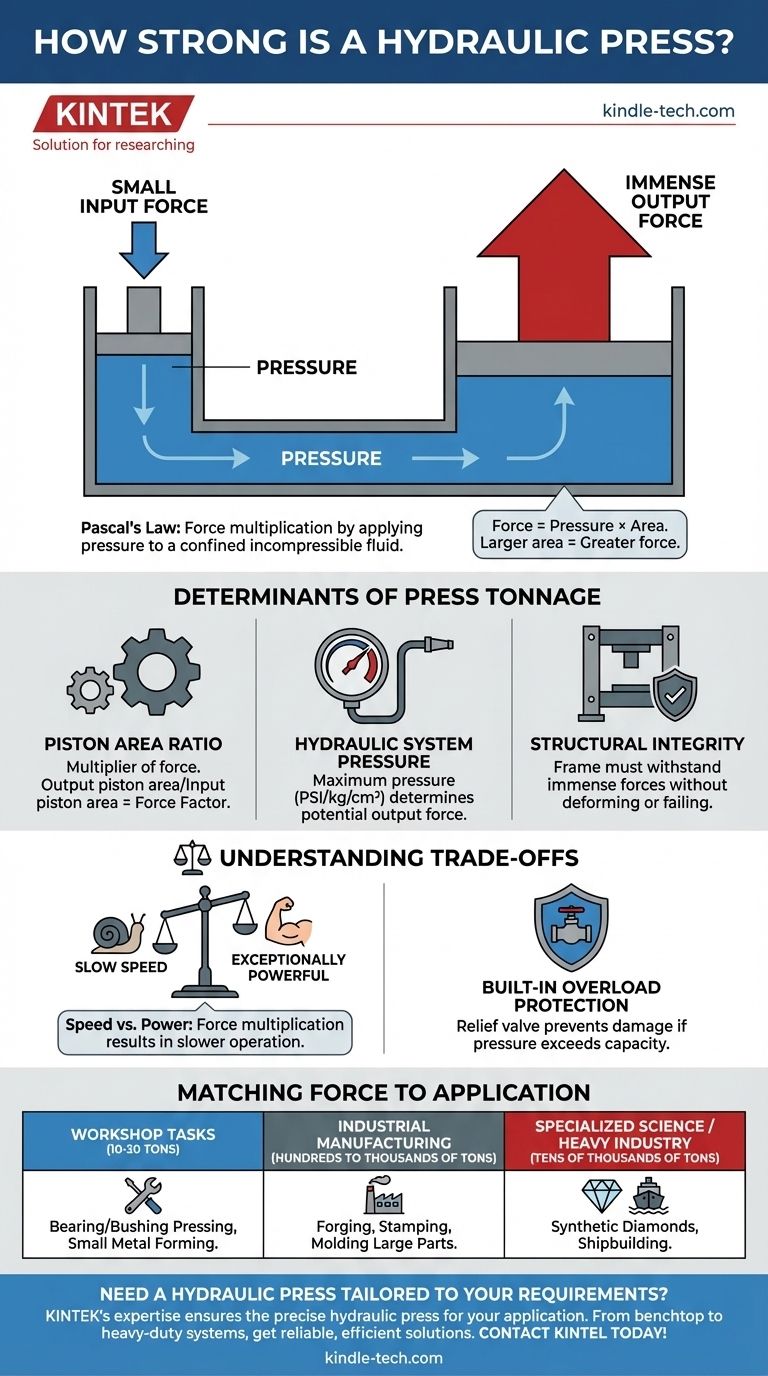

A hydraulic press derives its immense strength from Pascal's Law. It doesn't create energy, but rather multiplies force by applying pressure to a confined, incompressible fluid, allowing a small input effort to generate a massive output force.

The Principle Behind the Power: Pascal's Law

The reason a hydraulic press can exert such extreme force is rooted in fluid dynamics. The entire system is a practical application of a fundamental law of physics.

How Force is Multiplied

At the heart of every hydraulic press are two pistons of different sizes connected by a cylinder filled with an incompressible fluid, typically oil.

When a small force is applied to the smaller input piston, it creates pressure within the fluid. According to Pascal's Law, this pressure is transmitted equally and undiminished throughout the entire fluid.

This same pressure now acts on the much larger output piston. Because the surface area of the output piston is many times greater, the resulting force is multiplied by the same factor. A small push on one end creates a crushing force on the other.

The Role of Hydraulic Fluid

The choice of fluid is critical. Hydraulic oil is used because it is practically incompressible. This ensures that when pressure is applied, the energy is not wasted by squeezing the fluid itself.

Instead, nearly all the energy is transferred directly from the small piston to the large piston, making the force transfer incredibly efficient.

What Determines a Press's Tonnage?

The "tonnage" of a press refers to the maximum force it can safely exert. This rating is determined by a few key engineering factors.

Piston Area Ratio

The primary determinant of force multiplication is the ratio of the piston areas. If the output piston has a surface area 100 times larger than the input piston, the press will multiply the input force by a factor of 100.

Hydraulic System Pressure

The maximum pressure the hydraulic system can sustain also dictates the final output force. The pump, hoses, and seals are all rated for a specific pressure, often measured in kilograms per square centimeter (kg/cm²) or pounds per square inch (PSI). The higher the system's pressure rating, the greater the potential force.

Structural Integrity

Finally, the physical frame of the press must be strong enough to withstand the immense forces it generates. The frame's rigidity and strength provide the equal and opposite reaction force needed to press an object effectively without the machine deforming or failing.

Understanding the Trade-offs

While hydraulic presses offer immense power, that power comes with inherent operational characteristics and limitations.

Speed vs. Power

The force multiplication principle comes at the cost of speed and distance. To move the large output piston a small distance, the small input piston must travel a much longer distance.

This inverse relationship means that hydraulic presses are typically slow but exceptionally powerful. This makes them ideal for controlled pressing and forming, but less suitable for high-speed stamping operations.

Built-in Overload Protection

A key advantage of a hydraulic system is its natural overload protection. The maximum pressure is limited by a relief valve.

If the force required exceeds the press's capacity, the valve will open, preventing damage to the machine or the workpiece. This is a significant advantage over mechanical presses, which can catastrophically fail if overloaded.

Matching Force to the Application

The required strength of a hydraulic press is dictated entirely by the task it needs to perform.

- If your primary focus is workshop tasks: A 10- to 20-ton press is typically sufficient for jobs like pressing bearings, bushings, or performing small-scale metal forming.

- If your primary focus is industrial manufacturing: Forging, stamping, and molding large metal parts requires presses ranging from a few hundred to several thousand tons.

- If your primary focus is specialized science or heavy industry: Applications like creating synthetic diamonds or forming massive steel plates for ships can require presses with capacities in the tens of thousands of tons.

Ultimately, a hydraulic press is a masterclass in leveraging physics to achieve extraordinary results.

Summary Table:

| Force Range | Typical Applications |

|---|---|

| 10-20 tons | Workshop tasks (bearing/bushing pressing, small metal forming) |

| Hundreds to thousands of tons | Industrial manufacturing (forging, stamping, molding) |

| Tens of thousands of tons | Specialized science/heavy industry (synthetic diamonds, shipbuilding) |

Need a Hydraulic Press Tailored to Your Force Requirements?

Whether you're equipping a workshop or scaling up industrial production, KINTEK's expertise in lab and industrial equipment ensures you get the precise hydraulic press for your application. From benchtop models to heavy-duty systems, we provide reliable, efficient solutions backed by expert support.

Contact KINTEL today to discuss your project and discover the right press for your needs!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How does a laboratory hot press improve the microscopic structure of polymer-ceramic composite cathodes? | KINTEK

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- How is pressure generated and applied in a hot press? Master High-Intensity Hydraulic & Pneumatic Systems

- Why is a laboratory hot press necessary for the production of plastic crystal polymer electrolyte reinforced membranes?

- What are the advantages of hot pressing for PEO electrolytes? Achieve superior density and solvent-free performance.