The question of which press is "better" is fundamentally about matching the right tool to a specific task. A hydraulic press excels at generating immense, consistent force in a cost-effective and durable package. However, this power comes with trade-offs in speed, energy consumption, and the potential for fluid leaks, which are critical considerations when comparing it to an alternative like an electric press.

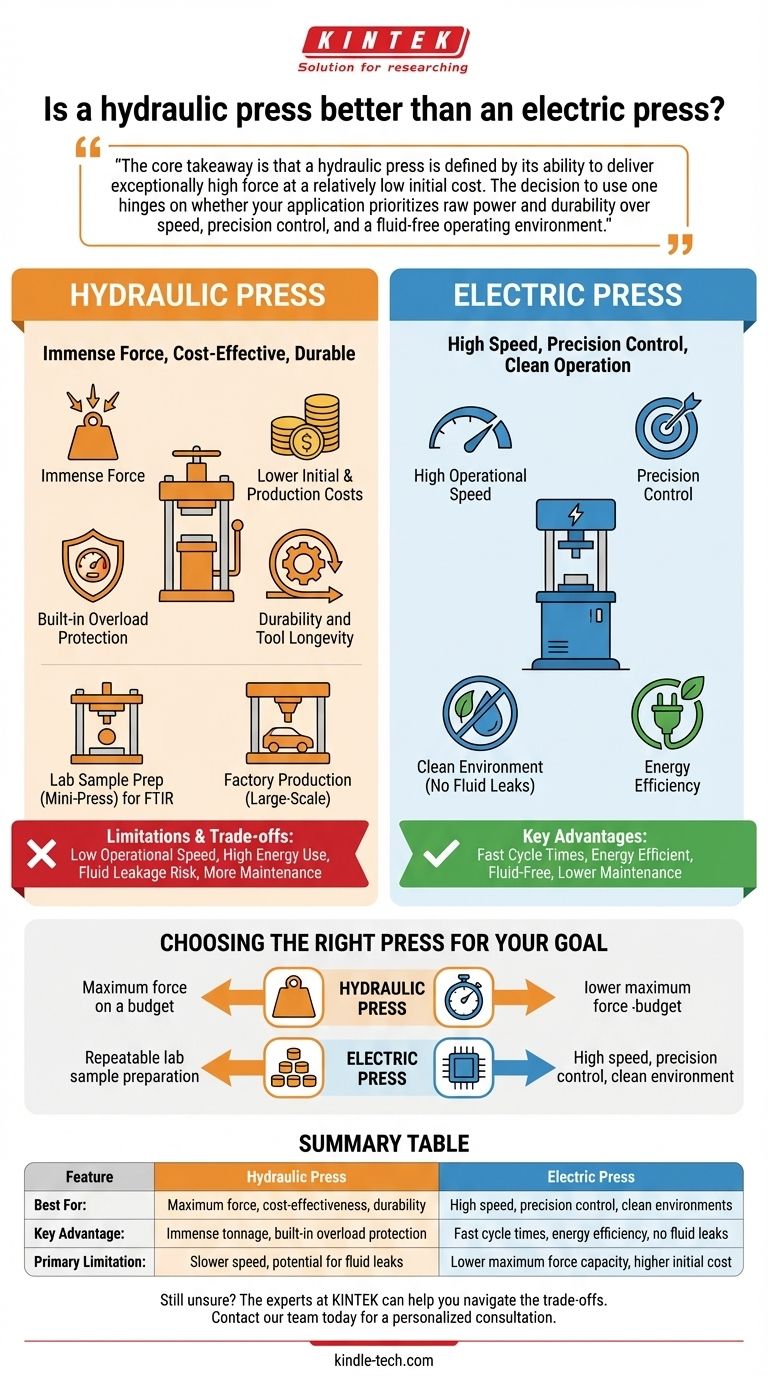

The core takeaway is that a hydraulic press is defined by its ability to deliver exceptionally high force at a relatively low initial cost. The decision to use one hinges on whether your application prioritizes raw power and durability over speed, precision control, and a fluid-free operating environment.

What Defines a Hydraulic Press?

A hydraulic press operates on a simple yet powerful principle: using a fluid to multiply force. An initial force applied to a small amount of contained hydraulic fluid generates immense pressure, which is then used to move a much larger piston to perform work.

The Principle of Immense Force Generation

This design is mechanically simple, with fewer moving parts than a complex mechanical press. This simplicity is the key to its ability to generate massive tonnage, provide built-in overload protection, and maintain a long service life with proper care.

Core Applications: From Lab to Factory Floor

Hydraulic presses are highly adaptable. In a laboratory, a compact mini-press is used for sample preparation, creating consistent pellets for analytical techniques like FTIR spectroscopy. In heavy industry, large-scale hydraulic presses are essential for manufacturing lightweight, high-strength parts for electric vehicles (EVs), ensuring both safety and energy efficiency.

The Key Advantages of a Hydraulic System

The primary benefits of a hydraulic press are directly tied to its fundamental design, centering on force, cost, and durability.

Unmatched Tonnage and Force Capacity

The defining advantage is the ability to generate immense pressure. This makes hydraulic systems the go-to choice for applications requiring very high tonnage, from forming metal panels to compressing materials into dense forms.

Lower Initial and Production Costs

With a simpler design and fewer parts compared to many mechanical alternatives, hydraulic presses often have a lower initial investment. This cost-effectiveness extends to the molds and tooling, which can also be less expensive.

Built-in Overload Protection

A hydraulic system has a natural, built-in pressure limit. Once the maximum set pressure is reached, the relief valve opens, preventing the press from exceeding its tonnage capacity. This inherent overload protection safeguards both the machine and the tooling from damage.

Durability and Tool Longevity

The smooth, controlled application of force reduces shock and vibration. This not only contributes to the increased strength and rigidity of the press itself but also extends the operational lifespan of the dies and tools being used.

Understanding the Trade-offs and Limitations

While powerful, hydraulic presses are not the ideal solution for every scenario. Their disadvantages are just as important to understand as their strengths.

Low Operational Speed and High Energy Use

Hydraulic systems are generally slower than their mechanical or electric counterparts. Furthermore, the pump must often run continuously to maintain pressure, leading to high energy consumption, even when the press is not actively performing a stroke.

The Risk of Hydraulic Fluid Leakage

The reliance on fluid is the system's greatest liability. Hydraulic fluid leakage is a constant concern, creating safety hazards (some fluids are flammable), environmental issues, and cleanup costs. This makes them less suitable for cleanroom or food-grade environments.

Maintenance and Fluid Management

Hydraulic systems require consistent maintenance. The fluid must be kept clean, filters must be changed, and seals must be monitored to prevent leaks. This need for more maintenance adds to the long-term operational cost and complexity.

Choosing the Right Press for Your Goal

The decision between a hydraulic press and an alternative like an all-electric press hinges entirely on your specific operational priorities.

- If your primary focus is maximum force on a budget: A hydraulic press is almost always the superior choice due to its simple design and ability to generate extremely high tonnage cost-effectively.

- If your primary focus is repeatable lab sample preparation: A compact hydraulic press offers the consistency and force needed for creating uniform pellets for techniques like FTIR analysis, where repeatability is key.

- If your primary focus is high speed, precision control, and a clean environment: The slower speed and potential for fluid leaks in a hydraulic system mean you should carefully evaluate alternatives like an electric press, which often excels in these areas.

By understanding that hydraulic systems trade speed and clean operation for raw power, you can confidently select the right tool for your specific job.

Summary Table:

| Feature | Hydraulic Press | Electric Press |

|---|---|---|

| Best For | Maximum force, cost-effectiveness, durability | High speed, precision control, clean environments |

| Key Advantage | Immense tonnage, built-in overload protection | Fast cycle times, energy efficiency, no fluid leaks |

| Primary Limitation | Slower speed, potential for fluid leaks | Lower maximum force capacity, higher initial cost |

Still unsure which press is right for your application? The experts at KINTEK can help you navigate the trade-offs. We specialize in providing the perfect lab equipment, from robust hydraulic presses for demanding sample preparation to precise electric models for sensitive workflows.

Contact our team today for a personalized consultation to enhance your lab's efficiency and achieve consistent, reliable results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Heat Press Machine

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

People Also Ask

- What is a hydraulic press used for? From Metal Forging to Lab Sample Prep

- What is XRF analysis used for? A Guide to Non-Destructive Elemental Analysis

- How does a laboratory hydraulic press contribute to Fe-Cu-Ni-Sn-VN green bodies? Master High-Density Compaction

- What is a wood pellet mill? Turn Waste Biomass into High-Density Fuel

- What is the role of a high-pressure rolling system in ceramic MFC chassis? Ensure Uniformity and Peak Performance

- How does a laboratory high-pressure hydraulic press influence B4C ceramic preforms? Optimize Your Ceramic Skeleton

- How does a laboratory hydraulic press contribute to green bodies for solid-state batteries? Optimize Your Cell Density

- What are the steps involved in sample preparation? A Guide to Accurate and Reliable Analysis