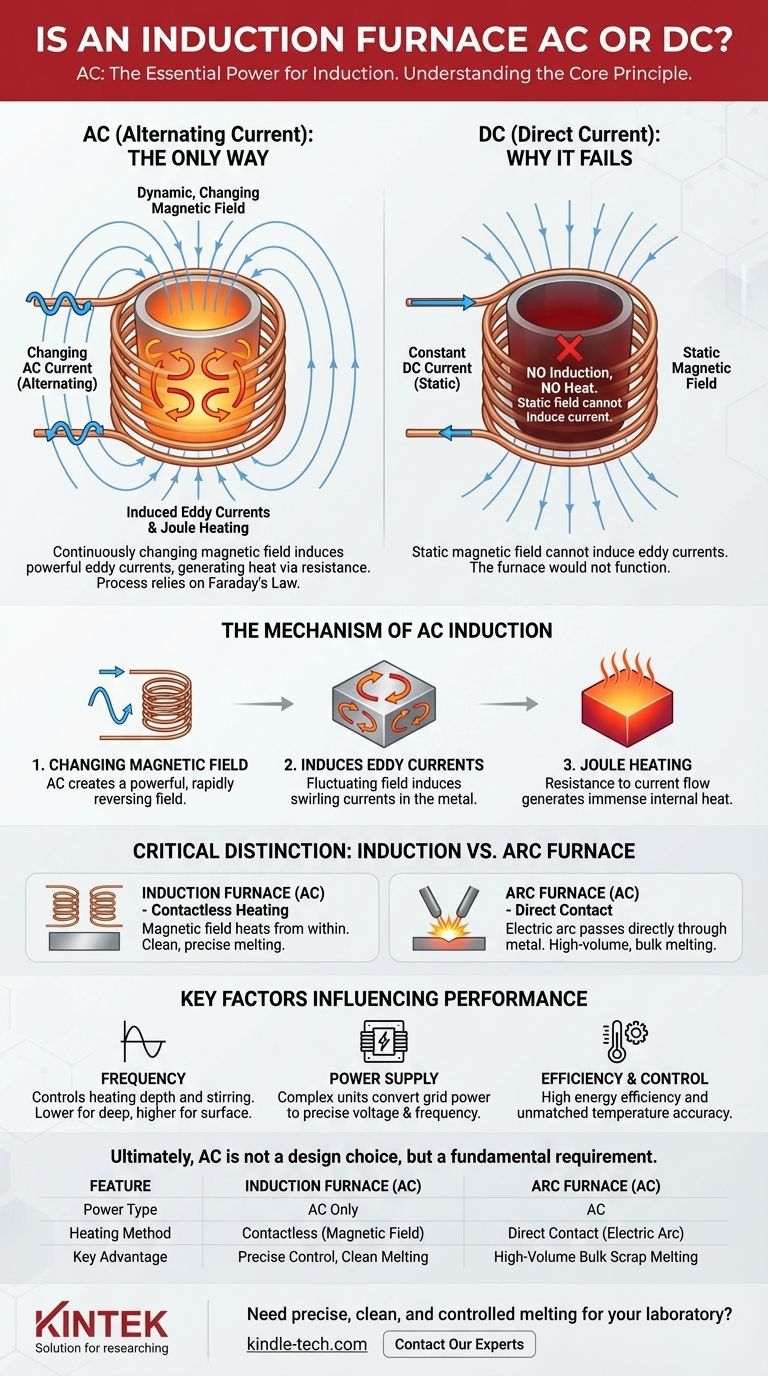

By definition, an induction furnace is an AC (Alternating Current) device. The entire principle of induction heating relies on the continuously changing magnetic field generated by an alternating current. Using Direct Current (DC) would not produce the required effect, as it creates a static magnetic field that cannot induce heat in the target material.

An induction furnace operates like a transformer. The furnace's coil acts as the primary winding, and the metal charge inside acts as a single-turn secondary winding. This relationship, known as electromagnetic induction, is only possible with the fluctuating magnetic field that an alternating current can produce.

The Core Principle: Why AC is Non-Negotiable

The operation of an induction furnace is a direct application of Faraday's Law of Induction. This physical law dictates that a current will only be induced in a conductor when it is exposed to a changing magnetic field.

Creating the Magnetic Field

A large coil, typically made of copper tubing, surrounds the crucible containing the metal. A powerful alternating current is passed through this coil.

Inducing Eddy Currents

As the AC current flows and rapidly reverses direction, it generates a strong, time-varying magnetic field around the coil. This magnetic field penetrates the conductive metal placed inside the furnace.

This changing magnetic field, in turn, induces powerful, swirling electrical currents within the metal itself. These are known as eddy currents.

Generating Heat Through Resistance

The metal has inherent electrical resistance. As these strong eddy currents flow against this resistance, they generate immense heat through a process called Joule heating. It is this internally generated heat that causes the metal to melt.

Why DC Fails for Induction

If you were to use Direct Current (DC), it would create a powerful but completely static magnetic field. Because the field is not changing, it cannot induce any eddy currents in the metal charge. No current means no Joule heating, and the furnace would not function.

Induction vs. Arc Furnace: A Critical Distinction

It's common to confuse different types of electric furnaces. The provided reference describes an AC electric arc furnace, which operates on a completely different principle.

The Induction Method (Contactless Heating)

An induction furnace uses a magnetic field to heat the material from within. There is no direct electrical contact between the power source's coil and the metal being melted. This results in a very clean and controlled melting process.

The Arc Method (Direct Contact)

An AC electric arc furnace, by contrast, passes a massive current directly through the metal charge via large graphite electrodes. This creates an extremely hot electric arc between the electrodes and the metal, which provides the melting energy. The metal itself is part of the circuit.

Understanding the Trade-offs

While the AC requirement is absolute, several factors influence the furnace's design and performance.

The Importance of Frequency

The frequency of the alternating current is a critical control parameter. Lower frequencies (near grid level) penetrate deeper into the metal bath, causing significant stirring. Higher frequencies heat the surface of the metal more rapidly and are used for smaller melts or surface hardening applications.

Power Supply Complexity

Induction furnaces require sophisticated power supplies. These units take standard grid power (at 50 or 60 Hz) and convert it to the precise voltage and frequency required for the specific melting application, which can range from hundreds to thousands of Hertz.

Efficiency and Control

The primary advantage of induction is its high efficiency and precise control. Since the heat is generated directly within the workpiece, energy loss is minimized, and temperature can be managed with exceptional accuracy.

Making the Right Choice for Your Goal

Understanding the fundamental power requirement helps clarify the technology's core strengths and ideal applications.

- If your primary focus is precise, clean, and controlled melting: The AC-powered, contactless heating of an induction furnace provides unmatched control over metallurgy and temperature.

- If your primary focus is large-scale, high-volume melting of raw scrap: An AC electric arc furnace is often the more robust choice, as its direct heating method is extremely effective for bulk processing.

- If you are designing a heating system: Remember that the AC frequency is as critical as the current. The choice of frequency directly dictates the depth, speed, and efficiency of the heating process.

Ultimately, an induction furnace's reliance on alternating current is not a design choice but a fundamental requirement of its underlying physical principle.

Summary Table:

| Feature | Induction Furnace (AC) | Arc Furnace (AC) |

|---|---|---|

| Power Type | Alternating Current (AC) only | Alternating Current (AC) |

| Heating Method | Contactless, via magnetic field & eddy currents | Direct contact, via electric arc |

| Principle | Electromagnetic induction (Faraday's Law) | Joule heating from direct current flow |

| Key Advantage | Precise temperature control, clean melting | High-volume melting of bulk scrap |

Need precise, clean, and controlled melting for your laboratory? KINTEK specializes in high-efficiency induction furnaces and lab equipment, delivering unmatched temperature accuracy and metallurgical control. Contact our experts today to find the perfect heating solution for your research or production needs!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What is the common operating temperature in a furnace? A Guide to Industrial Heat Treatment Ranges

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control