Yes, deposition is the direct reverse of sublimation. They are two sides of the same coin, describing a phase transition where a substance goes directly between the solid and gaseous states, completely bypassing the liquid phase. Sublimation is the process of a solid turning directly into a gas, while deposition is the process of a gas turning directly into a solid.

Deposition and sublimation are complementary phase transitions. Sublimation absorbs energy to change a solid into a gas, while deposition releases that same energy to change a gas back into a solid, all without passing through a liquid state.

Defining the Processes: A Direct Comparison

To grasp the relationship, it's essential to define each process clearly. They represent a direct pathway between the most ordered state of matter (solid) and the most disordered (gas).

Sublimation: Solid to Gas

Sublimation occurs when molecules in a solid gain enough energy to break free from their rigid structure and escape directly into the air as a gas. This is an endothermic process, meaning it requires an input of energy, typically heat.

A classic example is a block of dry ice (solid carbon dioxide) "smoking" at room temperature. It isn't melting into a liquid; it's sublimating directly into carbon dioxide gas.

Deposition: Gas to Solid

Deposition is the exact opposite. It happens when molecules in a gaseous state cool down so rapidly they lose energy and lock directly into a fixed, solid crystal structure. This is an exothermic process, as it releases energy into the environment.

The most common example is frost forming on a cold windowpane overnight. Water vapor (a gas) in the air comes into contact with the cold glass, loses energy, and turns directly into ice crystals (a solid).

The Role of Energy and Molecular Order

The direction of the change—whether it's sublimation or deposition—is determined by the flow of energy.

Absorbing Energy to Create Disorder

For sublimation to occur, the molecules in a solid's crystal lattice must absorb energy. This energy increases their vibration until they can overcome the forces holding them together, allowing them to escape as a free-moving gas. The system moves from a state of high order (solid) to high disorder (gas).

Releasing Energy to Create Order

For deposition, the opposite is true. Gas molecules, which are moving randomly and rapidly, must lose energy. As they slow down, the attractive forces between them can take hold, pulling them into an ordered, rigid crystalline structure. The system moves from high disorder (gas) to high order (solid).

Understanding the Context: Why Aren't These Processes More Common?

We are surrounded by examples of melting ice and boiling water, but sublimation and deposition seem less frequent. This is due to the specific environmental conditions required.

The Importance of Pressure and Temperature

Every substance has a "triple point," a unique combination of temperature and pressure at which its solid, liquid, and gaseous phases can coexist in equilibrium. Sublimation and deposition occur at temperatures and pressures below this triple point.

For water, this pressure is very low, which is why we typically see ice melt into water before it evaporates. However, in the upper atmosphere where pressure is low, snow and ice can form directly from water vapor via deposition.

Bypassing the Liquid State

The liquid phase acts as an intermediate state of energy and molecular order. Bypassing it requires a jump in energy (sublimation) or a rapid drop (deposition) under pressure conditions that don't favor the liquid form. This is why these processes are dominant for substances like carbon dioxide at standard atmospheric pressure but less common for water.

Making the Right Choice for Your Goal

Understanding this relationship helps you identify and predict how materials will behave in different environments.

- If your primary focus is observing a solid "vanish" without melting: You are witnessing sublimation, where energy is being absorbed to turn a solid directly to a gas.

- If your primary focus is observing frost, snow, or soot form from the air: You are witnessing deposition, where a gas is rapidly cooled and releases energy to form a solid.

Recognizing deposition and sublimation as a reversible pair is fundamental to mastering the complete picture of phase transitions in matter.

Summary Table:

| Process | Phase Change | Energy Change | Common Example |

|---|---|---|---|

| Sublimation | Solid → Gas | Endothermic (Absorbs Energy) | Dry ice 'smoking' at room temperature |

| Deposition | Gas → Solid | Exothermic (Releases Energy) | Frost forming on a cold windowpane |

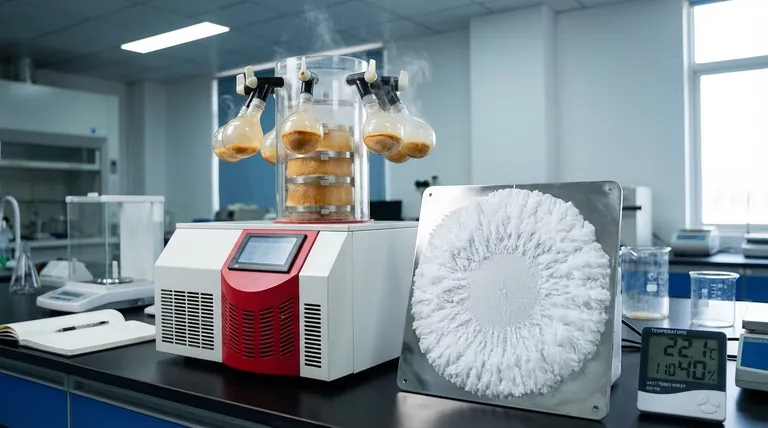

Need precise control over phase transitions in your lab? KINTEK specializes in high-quality lab equipment and consumables, including environmental chambers and temperature control systems, to help you accurately study processes like sublimation and deposition. Contact our experts today to find the perfect solution for your laboratory's unique research needs!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What are the types of sintering in powder metallurgy? A Guide to Solid-State, Liquid-Phase & Pressure Methods

- What is the importance of sintering? Unlock Strength, Density, and Complex Part Production

- What is the analytical method XRF? A Non-Destructive Guide to Elemental Analysis

- What increases tensile strength? Key Methods to Enhance Material Strength and Performance

- What are the sources of materials for biochar production? From Wood to Waste, Choose the Right Feedstock

- What are the parameters of sintering? Mastering Temperature, Time, Pressure & Composition

- What temperature does KBr dry at for IR? The Key to Moisture-Free, High-Quality Spectra

- Why should hesperidin samples be stored in amber glass and ULT freezers? Preserve Bioactivity and Sample Integrity