Yes, a heat press machine is an excellent and highly popular tool for making t-shirts. It provides a versatile and cost-effective method for applying graphics, especially for small businesses, custom apparel shops, and hobbyists. The quality and durability of the final product, however, depend entirely on the type of transfer material used and the precision of the application.

A heat press is best understood not as a single printing method, but as a versatile platform for on-demand apparel creation. Its true strength lies in its unmatched flexibility for small batches and complex, full-color designs, offering a low-cost entry point that large-scale methods can't match.

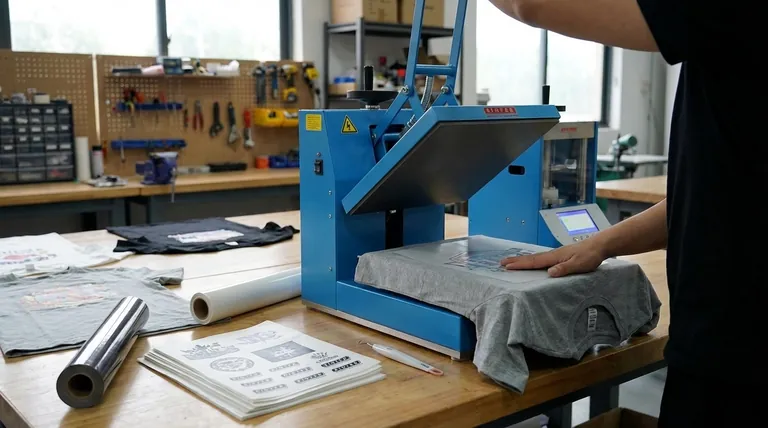

How a Heat Press Works: The Core Principle

A heat press is fundamentally a simple machine, but its effectiveness comes from its precision. It allows you to control the three most critical variables in heat transfer application.

Heat, Pressure, and Time

A high-quality heat press allows for precise control over these three elements. It applies a specific temperature and even pressure across the entire design for a set amount of time, ensuring the transfer adhesive bonds permanently and professionally to the fabric fibers. This is a significant advantage over using a standard home iron, which cannot provide consistent heat or pressure.

The Role of Transfer Materials

The heat press itself doesn't create the design; it applies a pre-made design from a carrier sheet onto the shirt. The type of transfer you choose dictates the final look, feel, and durability of the shirt.

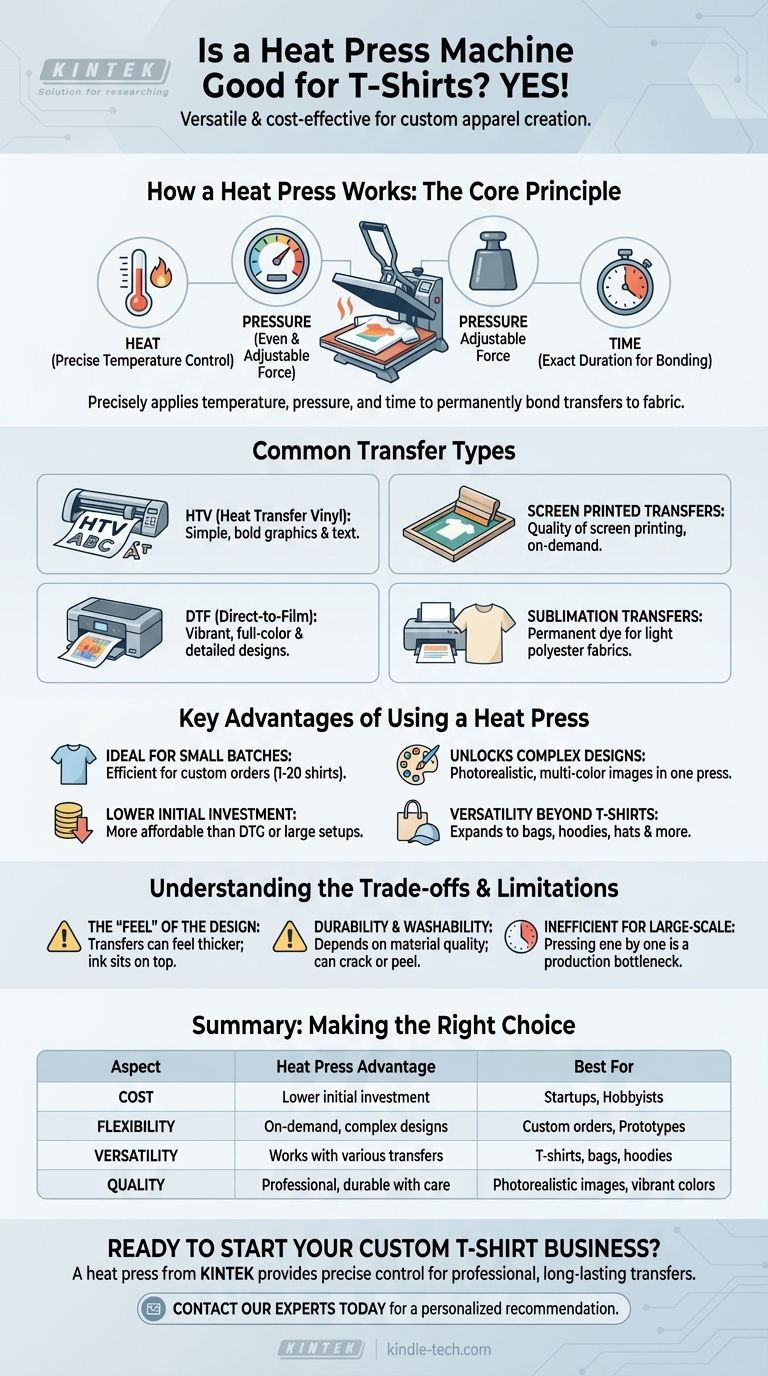

Common types include:

- Heat Transfer Vinyl (HTV): Vinyl sheets cut into shapes or letters. Best for simple, bold graphics and text.

- Screen Printed Transfers: A design is screen printed onto a special release paper. This combines the quality of screen printing with the on-demand convenience of a heat press.

- Direct-to-Film (DTF) Transfers: A newer technology where a design is digitally printed onto a film, which is then heat-pressed onto the shirt. This allows for vibrant, full-color, and highly detailed designs.

- Sublimation Transfers: A special ink is printed on paper. When heated, the ink turns into a gas and permanently dyes the polyester fibers of the shirt. This method only works on light-colored, high-polyester content fabrics.

Key Advantages of Using a Heat Press

For many applications, a heat press is the superior choice over other methods.

Ideal for Small Batches and Custom Orders

The setup for a heat press is minimal. This makes it incredibly efficient to produce a single custom shirt or a small run of 10-20 shirts, a task that would be prohibitively expensive and time-consuming with traditional screen printing.

Unlocks Full-Color and Complex Designs

With transfer types like DTF or printable vinyl, you can apply photorealistic images and intricate, multi-colored designs in a single press. Achieving this with screen printing would require multiple screens and complex registration, driving up costs and complexity.

Lower Initial Investment

A professional-grade heat press is significantly more affordable than a Direct-to-Garment (DTG) printer or a multi-color screen printing setup. This makes it the most accessible entry point for anyone starting a custom apparel business.

Versatility Beyond T-Shirts

The same heat press used for t-shirts can often be used for a wide range of other items, such as tote bags, hoodies, and coasters. With specialized attachments, you can even expand into hats and mugs.

Understanding the Trade-offs and Limitations

While powerful, a heat press is not the perfect solution for every scenario. Understanding its limitations is key to making an informed decision.

The "Feel" of the Design

Most heat press transfers, particularly standard HTV, create a layer that sits on top of the fabric. This can sometimes feel thicker or less flexible than screen printing ink, which soaks into the fabric. The "hand" (the way the design feels) is a critical quality factor for many brands.

Durability and Washability

The longevity of a heat-pressed design is good, but it depends heavily on the quality of the transfer material and the accuracy of the application. A poorly applied transfer or a low-quality vinyl can crack, peel, or fade over time. A properly cured screen print is often considered more durable for long-term, heavy wear.

Inefficiency for Large-Scale Production

Pressing shirts one by one is a bottleneck. If you need to produce several hundred or thousands of shirts with the same design, screen printing is vastly more time-efficient and cost-effective per unit.

Making the Right Choice for Your Goal

The decision to use a heat press should be based entirely on your specific objectives.

- If your primary focus is starting a small business (e.g., an Etsy shop) or making custom one-offs: A heat press is your ideal starting point due to its low cost and flexibility for on-demand orders.

- If your primary focus is creating large batches of a single design (e.g., for a brand or event): Screen printing will be more cost-effective and time-efficient.

- If your primary focus is producing photorealistic, premium-quality designs on cotton with a very soft feel: Direct-to-Garment (DTG) is the superior technology, but it requires a much larger investment and more maintenance.

- If your primary focus is on performance apparel (polyester): A heat press used for sublimation is the industry standard, offering unparalleled durability and quality with zero feel.

Ultimately, a heat press is a fantastic tool that empowers independent creators and small businesses to bring custom apparel ideas to life quickly and affordably.

Summary Table:

| Aspect | Heat Press Advantage | Best For |

|---|---|---|

| Cost | Lower initial investment | Startups, hobbyists, small businesses |

| Flexibility | On-demand, small batches, complex designs | Custom orders, Etsy shops, prototypes |

| Versatility | Works with HTV, DTF, sublimation transfers | T-shirts, hoodies, bags, and more |

| Quality | Professional, durable results with proper application | Photorealistic images, vibrant colors |

Ready to start your custom t-shirt business or elevate your hobby?

A heat press from KINTEK provides the precise temperature, pressure, and time control needed for professional, long-lasting transfers. Whether you're using Heat Transfer Vinyl (HTV), Direct-to-Film (DTF), or sublimation papers, our equipment ensures your designs bond perfectly to fabric.

KINTEK specializes in reliable lab and production equipment, including heat presses perfect for your apparel needs. Let us help you create high-quality custom wearables that stand out.

Contact our experts today for a personalized recommendation and take the first step towards bringing your designs to life!

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

People Also Ask

- How does a laboratory hot press contribute to the formation of PEO-LiTFSI films? Enhance Battery Research Efficiency

- What is laminating technique? Unlock the Power of Layered Materials for Superior Results

- What is a hydraulic hot press machine? A Guide to Force and Heat for Material Transformation

- What is the process of pressing sintering? A Guide to Powder Metallurgy & Ceramics Fabrication

- What role does a precision hot press play in the fabrication of TlBr crystals? Optimize Semiconductor Performance

- What is the difference between manual and air compressed heat press? Choose the Right Tool for Your Production Needs

- Why is a laboratory hot press required for Oxygen Depolarized Cathodes? Ensure Precision Molding and Conductivity.

- What role does a heated hydraulic press play in Cold Sintering (CSP)? Enhancing LATP-Halide Densification