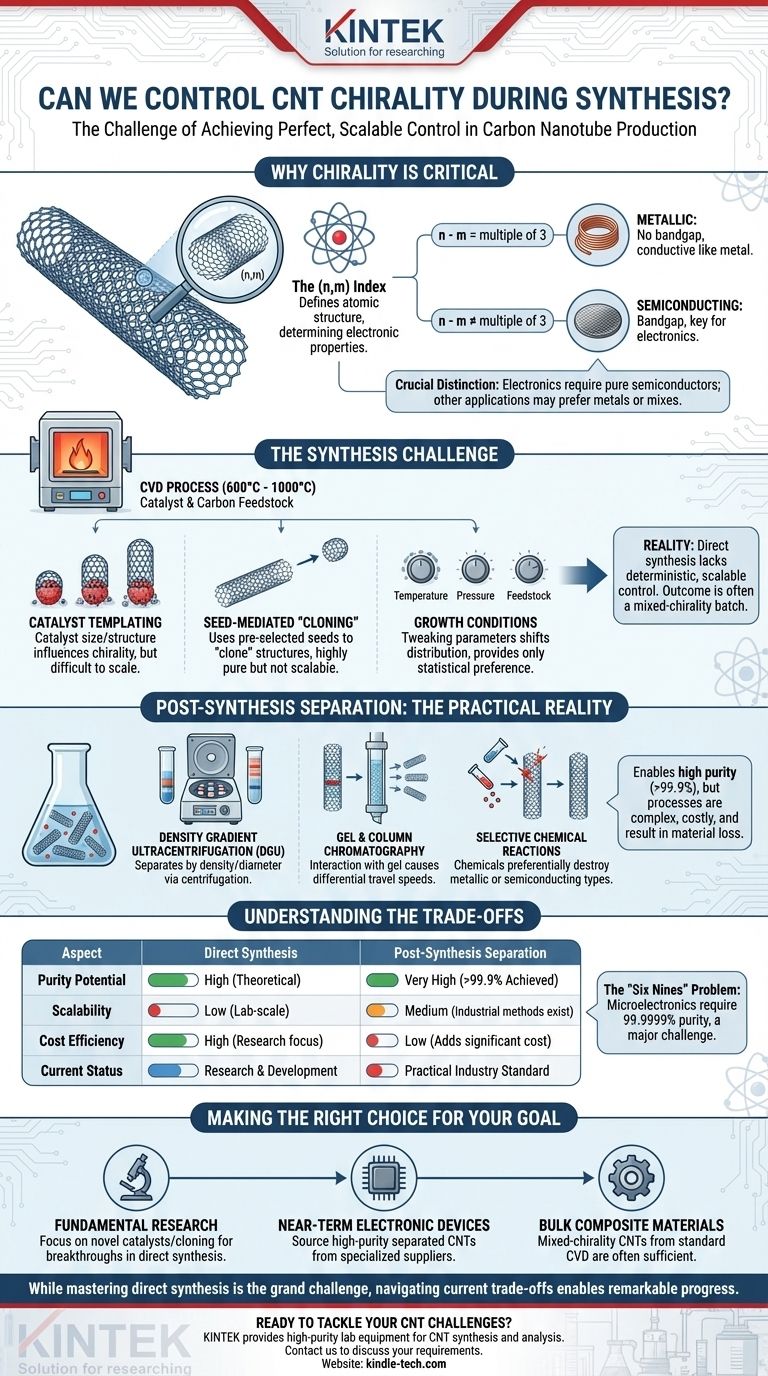

Yes, but not with perfect, scalable control. While researchers have demonstrated methods to preferentially grow carbon nanotubes (CNTs) of a specific chirality or electronic type, achieving 100% purity directly during synthesis on a large scale remains one of the most significant challenges in nanotechnology. The current state-of-the-art involves either highly specialized growth conditions that favor certain chiralities or, more commonly, purifying mixed-chirality CNTs after they have been grown.

The core challenge is that CNT formation is a high-temperature, dynamic process governed by complex atomic-level interactions between the catalyst and carbon atoms. While we can influence the outcome, we cannot yet deterministically script it like a manufacturing blueprint. Therefore, the practical solution for obtaining high-purity CNTs today largely relies on post-synthesis separation.

Why Chirality is the Critical Factor

To understand the challenge of controlled synthesis, we must first appreciate why it matters. The properties of a CNT are not generic; they are dictated entirely by its atomic structure, or chirality.

The (n,m) Index

Every CNT is defined by a pair of integers, (n,m), which describe how a flat sheet of graphene is "rolled up" to form the seamless cylinder. This index is the CNT's fundamental identity card.

Determining Electronic Properties

This (n,m) index directly determines the CNT's electronic bandgap. Based on a simple rule, the tube will be either metallic (like a copper wire) or semiconducting (like silicon).

- If n - m is a multiple of 3, the CNT is metallic or quasi-metallic, exhibiting no bandgap.

- If n - m is not a multiple of 3, the CNT is semiconducting, with a bandgap inversely proportional to its diameter.

This distinction is everything. For electronics, you need pure semiconductors. For transparent conductive films, you might prefer pure metals. A random mix is often unsuitable for high-performance applications.

The Challenge of Controlled Synthesis

Controlling chirality means controlling the atomic-level rolling process during the chaotic environment of chemical vapor deposition (CVD), which typically occurs at temperatures from 600°C to 1000°C.

The Catalyst as a Template

The most common synthesis method, CVD, grows CNTs from nanoparticle catalysts (e.g., iron, cobalt, nickel). The prevailing theory is that the catalyst nanoparticle's size and crystal structure act as a template for the CNT's cap, influencing which chirality is most energetically favorable to form.

Researchers have attempted to use specific crystalline orientations of solid catalysts to "template" the growth of a single, desired (n,m) structure. While successful in lab settings, this approach is extremely difficult to scale.

The "Cloning" Approach

Another promising strategy is "seed-mediated growth." This involves using a short segment of a CNT with a known, pre-selected chirality as a seed. Under the right conditions, this seed can be elongated, effectively "cloning" the desired structure. This produces ultra-pure CNTs but faces major hurdles in scalability and process control.

The Limits of Growth Conditions

Tweaking growth parameters like temperature, pressure, and the type of carbon feedstock (e.g., ethanol, methane) can shift the distribution of chiralities produced. For example, certain conditions might favor larger-diameter or smaller-diameter CNTs. However, this provides statistical preference, not deterministic control over a single (n,m) type.

The Practical Reality: Post-Synthesis Separation

Because direct synthesis of pure, single-chirality CNTs remains elusive at scale, the field has developed sophisticated methods to sort them after they are made.

Density Gradient Ultracentrifugation (DGU)

This is a workhorse technique in research. CNTs are wrapped with surfactants and spun in a centrifuge through a density gradient. CNTs with different chiralities (and thus slightly different diameters and densities) settle into distinct bands, which can then be physically extracted.

Gel and Column Chromatography

Similar to other chemical separation methods, CNTs can be passed through a column filled with a specialized gel. Different chiralities interact with the gel differently, causing them to travel through the column at different speeds, enabling separation.

Selective Chemical Reactions

Another approach involves using chemicals that selectively react with and destroy either metallic or semiconducting CNTs. For example, certain diazonium salts preferentially attack metallic CNTs, allowing them to be washed away, leaving behind a purified batch of semiconducting CNTs.

Understanding the Trade-offs

Choosing a path forward requires acknowledging the inherent compromises between purity, scale, and cost.

Purity vs. Scalability

Direct synthesis methods, like templated growth, offer the highest theoretical purity but are currently lab-scale curiosities. They are not yet viable for producing the kilograms of material needed for industrial applications.

The Cost of Separation

Post-synthesis separation techniques work, and some can produce very high-purity batches (>99.9%). However, these processes are multi-step, complex, and add significant cost and material loss, making the final product far more expensive.

The "Six Nines" Problem

For microelectronics, like building a CPU from CNT transistors, purity requirements are extreme. Even a 0.0001% contamination of metallic CNTs can create short circuits that render the entire device useless. This is often called the "99.9999% purity" problem, a benchmark that is incredibly difficult to achieve consistently and affordably.

Making the Right Choice for Your Goal

Your approach depends entirely on your application's tolerance for impurities.

- If your primary focus is fundamental research: Exploring novel catalyst engineering or seed-cloning techniques is where breakthroughs in direct synthesis will be made.

- If your primary focus is developing near-term electronic devices: Your best option is to source high-purity separated CNTs from a specialized supplier and focus your efforts on device integration.

- If your primary focus is bulk composite materials: The mixed-chirality CNTs produced by standard CVD are often sufficient, as their bulk mechanical, thermal, and electrical properties can enhance materials without needing electronic purity.

Ultimately, mastering the direct synthesis of single-chirality CNTs remains the field's grand challenge, but navigating the trade-offs of today's technologies allows for remarkable progress.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Direct Synthesis Control | Limited; influenced by catalyst & growth conditions, but not 100% scalable. |

| Chirality Impact | Determines electronic properties (metallic vs. semiconducting). |

| Current Solutions | Post-synthesis separation (e.g., DGU, chromatography) is the practical standard. |

| Trade-offs | Purity vs. scalability; separation adds cost but enables high-purity applications. |

Ready to tackle your CNT challenges? Whether you're advancing research or developing next-generation devices, KINTEK provides the high-purity lab equipment and consumables you need for reliable CNT synthesis and analysis. Contact our experts today to discuss how we can support your specific laboratory requirements!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the need of coating for wear resistance? Extend Component Life and Reduce Costs

- Can carbon nanotubes be used as carriers of drugs and antigens in the human body? Unlocking Targeted Therapies and Vaccines

- What type of method is magnetron sputtering? A High-Efficiency PVD Coating Technique

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the target temperature of magnetron sputtering? A Low-Temperature Process for Sensitive Materials

- What is the thickness of physical Vapour deposition? A Guide to Optimizing Your Coating Performance

- What are some common materials synthesized using CVD? Explore Nanostructures, Coatings, and High-Purity Films

- What is the synthesis process of graphene? A Guide to Top-Down and Bottom-Up Methods