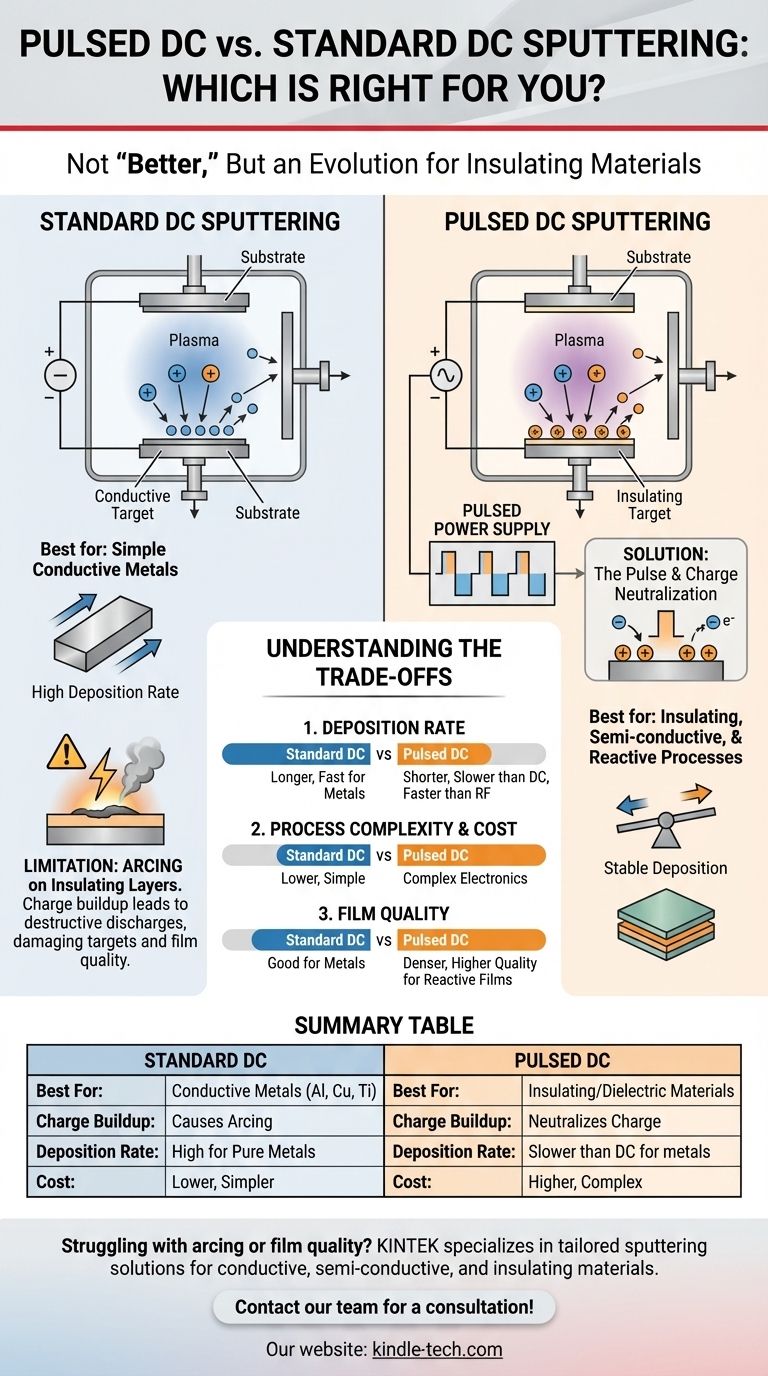

To be direct, pulsed DC sputtering is not inherently "better" than standard DC sputtering. Rather, it is an advanced evolution designed to solve a critical limitation of the standard DC method. The choice between them depends entirely on the type of material you are depositing. For simple conductive metals, standard DC is often faster and more cost-effective. For insulating or semi-conductive materials, pulsed DC is essential for a stable process.

The core difference comes down to managing electrical charge. Standard DC sputtering is the go-to for conductive targets but fails when insulating layers form, causing destructive arcing. Pulsed DC sputtering solves this arcing problem, expanding the process to a much wider range of materials at deposition rates often far exceeding those of RF sputtering.

The Foundation: Understanding Standard DC Sputtering

How It Works

In the simplest terms, standard DC (Direct Current) sputtering involves applying a constant negative voltage to a target material within a vacuum chamber. This creates a plasma, and positive ions from this plasma accelerate towards the negatively charged target, striking it with enough force to eject, or "sputter," atoms. These sputtered atoms then travel and deposit onto your substrate, forming a thin film.

Key Strengths

The primary advantages of standard DC sputtering are its simplicity, high deposition rate, and low cost. The power supplies are relatively inexpensive and easy to control, making it the most economical and efficient method for depositing conductive materials like pure metals and transparent conductive oxides.

The Critical Limitation: Arcing

The process works flawlessly as long as the target material remains electrically conductive. However, if you attempt to sputter an insulating (dielectric) material or use a reactive gas that forms an insulating layer on the target (like oxygen forming an oxide), a major problem arises.

Positive ions from the plasma become trapped on the target's non-conductive surface. This charge buildup eventually reaches a point where it catastrophically discharges in the form of a powerful arc. These arcs can damage the target, the power supply, and destroy the quality of the film being deposited.

The Evolution: How Pulsed DC Solves the Arcing Problem

The Core Mechanism: The Pulse

Pulsed DC sputtering addresses the arcing problem directly. Instead of a constant DC voltage, the power supply delivers the negative voltage in short, high-frequency bursts or pulses (typically in the tens to hundreds of kHz range).

The 'Off' Time is Key

Crucially, between each negative pulse, a brief reverse-polarity (positive) voltage is applied. This short positive pulse attracts electrons from the plasma, which effectively neutralize the positive charge that began accumulating on the target surface during the main sputtering pulse.

The Result: Stable, Arc-Free Deposition

By continuously neutralizing this charge buildup before it can reach a critical point, pulsed DC technology prevents arcing. This makes it possible to reliably sputter dielectric compounds or run reactive sputtering processes for extended periods without instability, bridging the gap between the capabilities of DC and RF systems.

Understanding the Trade-offs

Choosing a technology always involves balancing benefits and drawbacks. Pulsed DC is powerful, but it is not a universal replacement for standard DC.

Deposition Rate

While pulsed DC offers far higher deposition rates than RF for dielectric materials, it is typically slower than standard DC for depositing a pure, conductive metal. The brief "off" time in the duty cycle, while necessary, means less time is spent actively sputtering compared to a continuous DC process at the same peak power.

Process Complexity and Cost

Simplicity is a major advantage of standard DC. The power supplies are straightforward and less expensive. Pulsed DC power supplies are significantly more complex and costly due to the advanced electronics required to generate and control the high-frequency pulses and voltage reversals.

Film Quality and Density

In many reactive sputtering applications (e.g., depositing titanium nitride or aluminum oxide), pulsed DC can produce denser and higher-quality films. The high plasma density achieved during the peak of each pulse can lead to improved film morphology and stoichiometry compared to other methods.

Making the Right Choice for Your Application

Your decision should be guided by your specific material and process goals.

- If your primary focus is cost-effective deposition of pure metals (like aluminum, copper, or titanium): Standard DC sputtering is the superior choice for its unmatched speed, simplicity, and low equipment cost.

- If your primary focus is reactive sputtering (depositing oxides, nitrides) or sputtering semi-conductive materials: Pulsed DC sputtering is the essential technology to prevent arcing and ensure a stable, repeatable, and high-rate deposition process.

- If your primary focus is depositing highly insulating materials where deposition rate is not critical: RF sputtering remains a reliable option, but pulsed DC is often preferred in industrial settings for its significant speed advantage.

By understanding the fundamental role of charge buildup and arcing, you can confidently select the sputtering technique that aligns perfectly with your material, budget, and production goals.

Summary Table:

| Feature | Standard DC Sputtering | Pulsed DC Sputtering |

|---|---|---|

| Best For | Conductive metals (Al, Cu, Ti) | Insulating/dielectric materials, reactive processes |

| Charge Buildup | Causes arcing on insulating layers | Neutralizes charge, prevents arcing |

| Deposition Rate | High for pure metals | Slower than DC for metals, but faster than RF for dielectrics |

| Cost & Complexity | Lower cost, simpler power supply | Higher cost, more complex electronics |

| Film Quality | Good for metals | Denser, higher-quality films in reactive processes |

Struggling with arcing or film quality in your sputtering process? KINTEK specializes in lab equipment and consumables, providing tailored sputtering solutions for laboratories working with conductive, semi-conductive, and insulating materials. Our experts can help you choose the right technology—whether standard DC for cost-effective metal deposition or pulsed DC for stable reactive processes—to enhance your thin-film results and lab efficiency. Contact our team today for a consultation!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- Does nanomaterials have potential hazards to human health? Understanding the Risks and Safe Handling

- What is the science behind sintering? Mastering the Thermal Process for Stronger Materials

- What are the types of sputtering? A Guide to DC, RF, Magnetron, Ion Beam & Reactive Sputtering

- How does a benchtop orbital shaker facilitate the production of reducing sugars? Boost Cellulose Hydrolysis Yields

- What are the applications of ion beam sputtering? Achieve Unmatched Thin Film Quality for Demanding Applications

- Why are purge and vent ports necessary for sample reservoirs in fission product simulation systems? Ensure Data Accuracy

- What are the uses of biochar from pyrolysis? Engineer Its Properties for Your Specific Goal

- Is there a machine to test diamonds? A Guide to Modern Diamond Verification Technology