Yes, PVD coating is a highly durable and wear-resistant finish for watches. This advanced process bonds a thin layer of metal compounds to the watch's base material in a vacuum, creating a surface that is significantly harder and more resilient to scratches and corrosion than traditional plating methods.

While PVD coating offers exceptional durability for daily wear, it's crucial to understand that it is a surface treatment. It provides superior resistance to scuffs and fading but is not completely immune to deep scratches or extreme impacts that can expose the underlying steel.

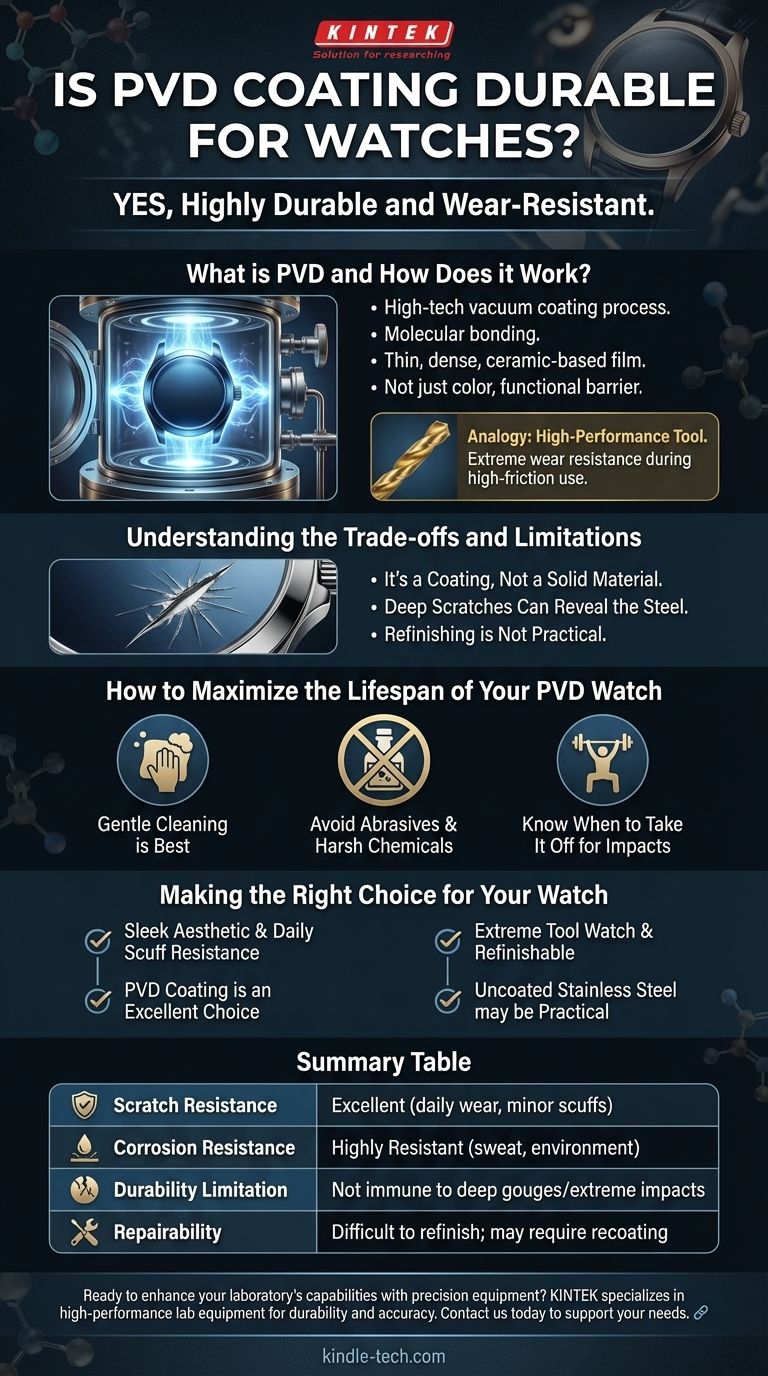

What is PVD and How Does it Work?

Physical Vapor Deposition (PVD) is a high-tech vacuum coating process that deposits a thin, dense film onto a surface. It's valued for its ability to improve the performance and aesthetics of an object without altering the properties of the base material.

A High-Energy Bonding Process

Unlike traditional plating that simply layers material on top, PVD uses a high-energy process inside a vacuum chamber to physically bond the coating to the stainless steel at a molecular level. This creates a far more permanent and robust finish.

More Than Just Color

While PVD is used to create popular black, gold, or gunmetal finishes on watches, its primary benefit is functional. The resulting ceramic-based layer is exceptionally hard, providing a protective barrier for the steel beneath it.

The Analogy of a High-Performance Tool

A common real-world example of PVD is the coating on high-end drill bits. The gold or black finish isn't just for looks; it provides extreme wear resistance during high-friction use. Even when a bit fails from heat or torque, the PVD coating itself often remains intact.

Understanding the Trade-offs and Limitations

PVD offers a clear advantage in scratch resistance for everyday situations, but it is not invincible. Objectivity requires understanding its limitations compared to uncoated stainless steel.

It's a Coating, Not a Solid Material

The primary limitation is that PVD is a very thin layer. While extremely hard, it is still only a surface treatment. It does not change the fundamental nature of the softer steel underneath.

Deep Scratches Can Reveal the Steel

For minor scuffs and daily bumps, PVD holds up remarkably well. However, a deep gouge or a significant impact against a hard, sharp surface can penetrate the coating and expose the silver-colored stainless steel below.

Refinishing is Not Practical

An uncoated stainless steel watch can have scratches polished or brushed out, effectively restoring its finish. A scratch that penetrates a PVD coating cannot be easily repaired, as the entire watch case would need to be stripped and re-coated by a specialist.

How to Maximize the Lifespan of Your PVD Watch

With proper care, a PVD-coated watch can maintain its original appearance for many years. The key is to protect it from the two things that can compromise the finish: abrasives and heavy impacts.

Gentle Cleaning is Best

Clean your PVD watch with a soft cloth using mild soap and warm water. This is sufficient to remove sweat, oils, and daily grime without harming the finish.

Avoid Abrasives and Harsh Chemicals

Never use abrasive cloths, polishes, or harsh chemical cleaners on a PVD coating. These products are designed to remove material and will damage or strip the finish.

Know When to Take It Off

To prevent deep scratches or impacts, remove your watch before engaging in activities like heavy-duty work, contact sports, or lifting weights where it could be struck against hard surfaces.

Making the Right Choice for Your Watch

Your decision should be based on how you intend to use the watch and what you value most in its appearance and longevity.

- If your primary focus is a sleek aesthetic and superior resistance to daily scuffs: PVD coating is an excellent choice that will keep your watch looking new for a long time.

- If your primary focus is a "tool watch" for extreme, hard-use environments: Uncoated stainless steel may be a more practical choice, as any deep scratches can be refinished over the watch's lifespan.

Ultimately, PVD coating offers a modern, high-performance finish that provides significant functional and aesthetic benefits for most watch owners.

Summary Table:

| Aspect | PVD Coating Performance |

|---|---|

| Scratch Resistance | Excellent for daily wear and minor scuffs |

| Corrosion Resistance | Highly resistant to sweat and environmental factors |

| Durability Limitation | Not immune to deep gouges or extreme impacts |

| Repairability | Difficult to refinish; entire case may need recoating |

Ready to enhance your laboratory's capabilities with precision equipment?

At KINTEK, we specialize in providing high-performance lab equipment and consumables tailored to meet the rigorous demands of modern laboratories. Whether you're conducting material testing or need reliable tools for your research, our products are designed for durability and accuracy.

Contact us today to discuss how KINTEK can support your laboratory needs and help you achieve superior results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition