In short, yes. Physical Vapor Deposition (PVD) is widely regarded as one of the most environmentally friendly coating processes available. Unlike traditional "wet" plating methods that rely on liquid chemical baths, PVD is a dry vacuum deposition technique that produces an exceptionally durable and clean finish with minimal environmental impact.

The core reason PVD is eco-friendly lies in its process, not just its materials. By physically depositing a thin film of material onto a surface within a sealed vacuum, it inherently avoids the toxic chemicals, hazardous waste, and air pollution that plague conventional coating methods like electroplating.

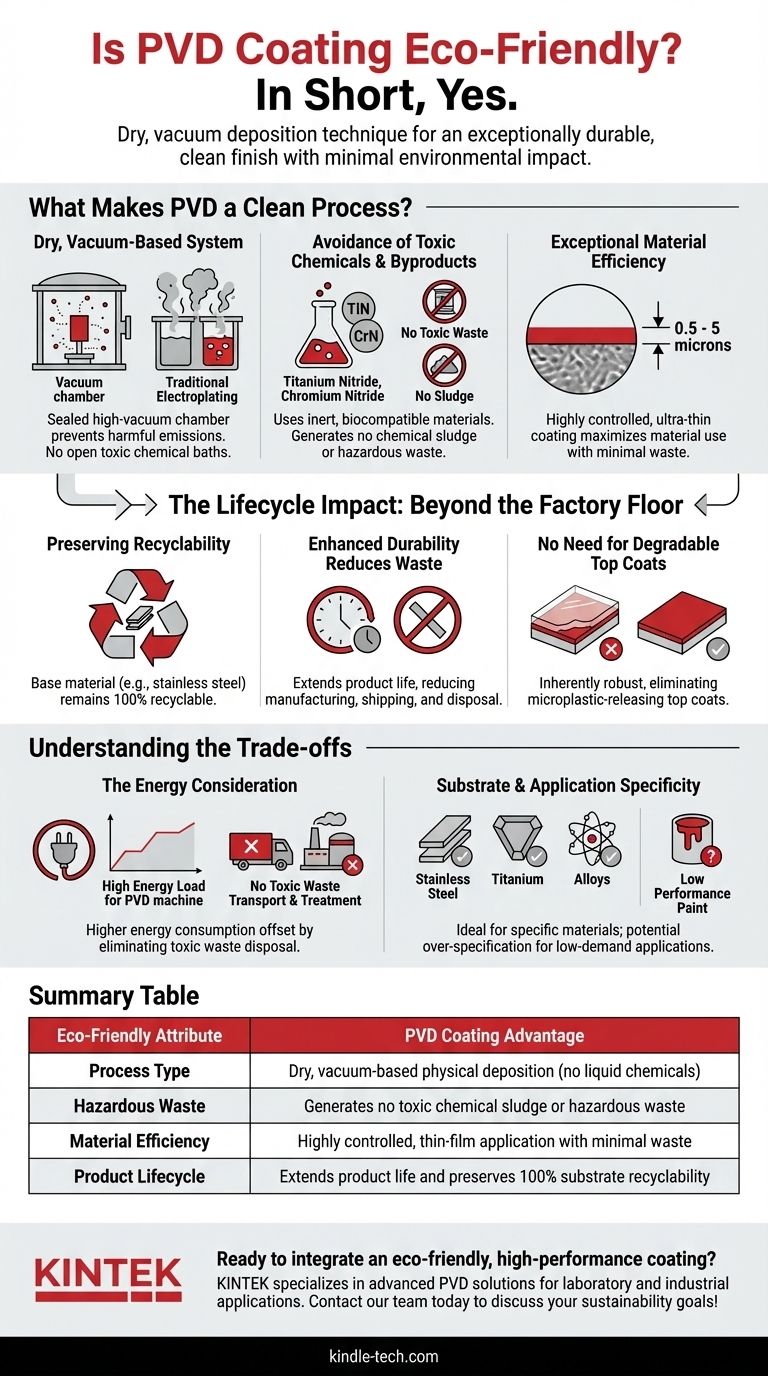

What Makes PVD an Environmentally Clean Process?

The environmental advantages of PVD are directly tied to the fundamental nature of how the coating is applied. It is a physical process, not a chemical one.

A Dry, Vacuum-Based System

PVD coating takes place inside a high-vacuum chamber. This sealed environment is critical, as it ensures that no harmful substances are released into the atmosphere during the process.

This stands in stark contrast to traditional electroplating, which involves submerging parts in open vats of toxic chemical solutions, creating hazardous fumes and wastewater.

Avoidance of Toxic Chemicals and Byproducts

The PVD process does not use the harsh acids, cyanides, or hexavalent chromium common in electroplating. The materials used for the coating itself, such as Titanium Nitride (TiN) and Chromium Nitride (CrN), are inert and biocompatible.

Because it is a physical deposition method, it generates no toxic chemical sludge or hazardous waste that requires specialized and costly disposal.

Exceptional Material Efficiency

PVD applies an extremely thin—yet durable—coating, typically between 0.5 and 5 microns. The process is highly controlled, ensuring the coating material is deposited directly onto the target surface with very little waste.

The Lifecycle Impact: Beyond the Factory Floor

PVD's environmental benefits extend far beyond the initial application, influencing the entire lifecycle of the product.

Preserving Recyclability

A key advantage is that PVD coating does not alter the fundamental nature of the substrate material. A PVD-coated piece of stainless steel remains 100% recyclable, preserving the value and reusability of the base metal.

Enhanced Durability Reduces Waste

The hardness and corrosion resistance of PVD coatings significantly extend the functional life of a product. A longer-lasting product means fewer replacements are needed, which in turn reduces the environmental footprint associated with manufacturing, shipping, and disposal.

No Need for Degradable Top Coats

Many traditional finishes require a clear top coat for protection, which can degrade, chip, or yellow over time, sometimes releasing microplastics or other substances. PVD coatings are inherently robust and do not require these additional layers.

Understanding the Trade-offs

While highly advantageous, no industrial process is without context. Understanding the trade-offs is key to making an informed decision.

The Energy Consideration

Creating a vacuum and generating the plasma used in PVD are energy-intensive processes. The machinery requires a significant electrical load compared to a simple chemical bath.

However, this energy cost is often offset by the complete elimination of resources needed for toxic waste transport, treatment, and long-term environmental cleanup associated with alternative methods.

Substrate and Application Specificity

PVD works best on materials that can withstand the vacuum process and, in some cases, elevated temperatures. It is an ideal finish for metals like stainless steel, titanium, and certain alloys.

It is a high-performance finish, making it a potential "over-specification" for applications where simple paint or powder coating would suffice and performance demands are low.

Making the Right Choice for Your Application

Choosing a coating technology requires balancing performance requirements with environmental goals.

- If your primary focus is eliminating hazardous waste and toxic chemicals: PVD is an exceptional choice, as it completely avoids the chemical baths and hazardous sludge of processes like electroplating.

- If your primary focus is product lifecycle and circularity: PVD excels by creating a durable finish that extends product life while preserving the full recyclability of the base metal.

- If your primary focus is high performance without environmental compromise: PVD delivers superior hardness, corrosion resistance, and durability, making it the preferred clean technology for demanding industries like medical and aerospace.

By prioritizing a clean, physical process over a reactive chemical one, PVD allows you to achieve a superior finish that aligns high performance with genuine environmental responsibility.

Summary Table:

| Eco-Friendly Attribute | PVD Coating Advantage |

|---|---|

| Process Type | Dry, vacuum-based physical deposition (no liquid chemicals) |

| Hazardous Waste | Generates no toxic chemical sludge or hazardous waste |

| Material Efficiency | Highly controlled, thin-film application with minimal waste |

| Product Lifecycle | Extends product life and preserves 100% substrate recyclability |

Ready to integrate an eco-friendly, high-performance coating into your product line? KINTEK specializes in advanced PVD coating solutions for laboratory and industrial applications. Our expertise ensures you get a durable, clean finish that aligns with your sustainability goals. Contact our team today to discuss how PVD coating can benefit your specific needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition