Yes, Physical Vapor Deposition (PVD) is widely regarded as one of the most environmentally friendly coating processes available. Unlike traditional methods like electroplating, PVD is a dry, vacuum-based process that produces no hazardous waste, toxic gases, or water pollution. It enhances a product's durability without compromising the recyclability of the base material.

The core reason PVD is eco-friendly lies in what it eliminates: the toxic chemical baths, contaminated water, and hazardous sludge characteristic of older plating technologies. It is a clean, contained process that adds durability, thereby reducing long-term waste.

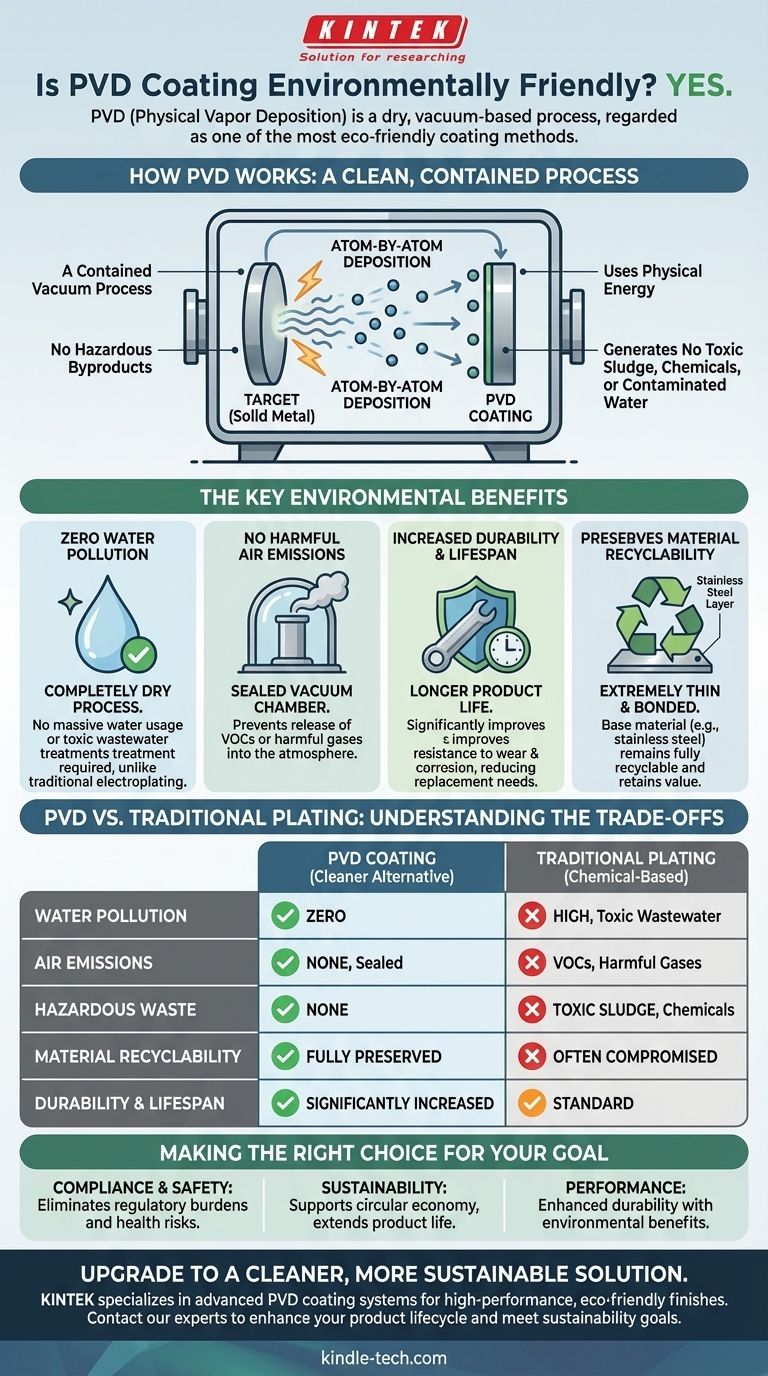

How PVD Works (And Why It's Clean)

Understanding the PVD mechanism reveals why it has such a minimal environmental footprint. The entire process is fundamentally different from traditional "wet" plating methods.

A Contained Vacuum Process

The PVD coating process takes place entirely within a sealed vacuum chamber. This containment is critical, as it ensures that no byproducts or process materials escape into the atmosphere.

Atom-by-Atom Deposition

A solid, high-purity metal material, such as titanium or chromium (known as a "target"), is vaporized through a high-energy process like sputtering or arc discharge. These vaporized atoms or ions then travel through the vacuum and deposit onto the part, forming a thin, dense, and highly bonded coating one atom at a time.

No Hazardous Byproducts

Because the process uses physical energy to vaporize clean, solid metals in a vacuum, it generates no harmful outputs. There are no chemical solutions to dispose of, no toxic sludge to manage, and no contaminated water to treat.

The Key Environmental Benefits of PVD

The clean nature of the PVD process translates into several distinct environmental advantages over traditional finishing techniques.

Zero Water Pollution

PVD is a completely dry process. This stands in stark contrast to electroplating, which requires massive amounts of water that become contaminated with heavy metals and toxic chemicals, necessitating complex and costly wastewater treatment.

No Harmful Air Emissions

The sealed vacuum chamber prevents the release of any volatile organic compounds (VOCs) or other harmful gases into the atmosphere.

Increased Durability and Product Lifespan

PVD coatings significantly improve a product's resistance to wear, corrosion, and oxidation. This increased durability means the product lasts longer, reducing the need for replacements and conserving the resources that would be used to manufacture new items.

Preserves Material Recyclability

The PVD coating is extremely thin (typically 0.5 to 5 microns) and metallurgically bonded to the surface. It does not alter the fundamental properties of the base material, such as stainless steel, which remains fully recyclable and retains its value.

Understanding the Trade-offs: PVD vs. Traditional Plating

While PVD is a superior choice for environmental impact, it's important to understand the context of what it replaces.

The Problem with Traditional Plating

Methods like chrome plating often rely on hexavalent chromium, a known carcinogen, and involve immersing parts in baths of hazardous acids and cyanide solutions. This creates significant worker safety risks and a substantial hazardous waste disposal burden.

The Energy Consideration

Like any advanced manufacturing process, PVD requires a significant input of electrical energy to create the vacuum and vaporize the source metals. However, this energy consumption is often offset by the complete elimination of resources needed for water procurement, wastewater treatment, and hazardous waste transport and disposal.

A Modern, Cleaner Alternative

PVD represents a technological shift away from chemical-based processes to physics-based ones. It solves the performance requirements of coating while designing out the environmental hazards inherent in older methods from the very beginning.

Making the Right Choice for Your Goal

Evaluating PVD for your application means balancing performance needs with environmental responsibility.

- If your primary focus is compliance and safety: PVD is the superior choice, as it eliminates the regulatory burdens and health risks associated with storing, using, and disposing of hazardous plating chemicals.

- If your primary focus is sustainability: PVD supports a circular economy by extending product life and preserving the complete recyclability of the base material.

- If your primary focus is performance: The enhanced durability, hardness, and corrosion resistance provided by PVD often make it the best technical solution, with its environmental benefits being a critical added advantage.

Ultimately, choosing PVD is a decision for a modern, high-performance, and environmentally responsible finishing process.

Summary Table:

| Environmental Aspect | PVD Coating | Traditional Plating |

|---|---|---|

| Water Pollution | Zero | High (toxic wastewater) |

| Air Emissions | None (vacuum sealed) | VOCs, harmful gases |

| Hazardous Waste | None | Toxic sludge, chemicals |

| Material Recyclability | Fully preserved | Often compromised |

| Durability & Lifespan | Significantly increased | Standard |

Upgrade to a cleaner, more sustainable coating solution for your products. KINTEK specializes in advanced PVD coating systems that deliver superior durability while eliminating environmental hazards. Our lab equipment and consumables are designed to help you achieve high-performance, eco-friendly finishes without the waste and pollution of traditional methods. Contact our experts today to learn how PVD can enhance your product lifecycle and meet your sustainability goals.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition