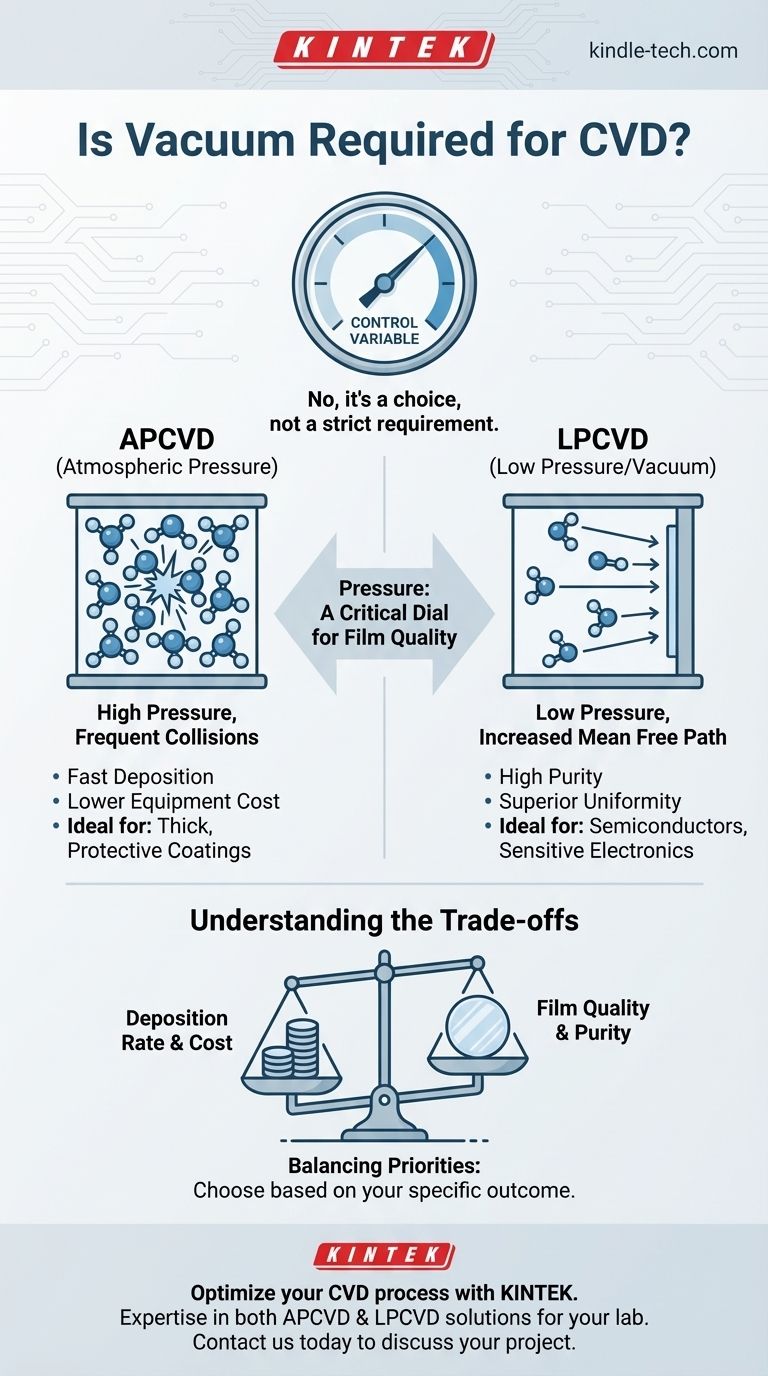

No, a vacuum is not a strict requirement for all Chemical Vapor Deposition (CVD) processes. While many advanced CVD applications operate under low-pressure (vacuum) conditions to achieve high purity, the technique can also be performed at standard atmospheric pressure. The choice of pressure is a critical process parameter that directly influences the quality and properties of the final material.

The core takeaway is that operating pressure in CVD is not a simple requirement but a fundamental control variable. The decision to use a vacuum is a strategic trade-off between deposition speed and the ultimate purity, uniformity, and conformality of the deposited film.

Why Pressure is a Critical Variable in CVD

Chemical Vapor Deposition is fundamentally a process of chemistry and transport. A precursor gas is introduced into a chamber where it reacts on a heated substrate to form a solid film. The pressure inside that chamber dictates how the gas molecules behave, which in turn defines the quality of the film.

The Role of Atmospheric Pressure CVD (APCVD)

In its simplest form, CVD can be performed in a chamber at normal atmospheric pressure. This method is known as APCVD.

At this higher pressure, gas molecules are densely packed and collide frequently. This leads to a very high rate of deposition, making the process fast and efficient for certain applications.

The Advantage of Low-Pressure CVD (LPCVD)

To gain more control, the pressure in the chamber is often reduced, creating a partial vacuum. This is known as Low-Pressure CVD (LPCVD).

Reducing the pressure increases the mean free path—the average distance a gas molecule travels before colliding with another. This simple change has profound effects.

With fewer collisions in the gas phase, the precursor molecules are more likely to travel undisturbed to the heated substrate. The chemical reaction is therefore dominated by what happens on the surface, not in the space above it.

The Impact on Film Quality

This shift from gas-phase to surface-dominated reactions is key to quality.

LPCVD processes significantly reduce the risk of unwanted particles forming in the gas and falling onto the substrate, which would create defects. The result is a film with higher purity and superior uniformity across the entire substrate, which is why it is common in the semiconductor industry.

Understanding the Trade-offs

Choosing the operating pressure for a CVD process involves balancing competing priorities. There is no single "best" method; the optimal choice depends entirely on the application's requirements.

Deposition Rate vs. Film Quality

This is the primary trade-off.

APCVD offers a much faster deposition rate, making it ideal for applying thick, protective coatings where minor imperfections are not critical.

LPCVD, while slower, produces the exceptionally pure and uniform films required for high-performance electronics and other sensitive components.

Equipment Complexity and Cost

Simplicity is a major advantage of APCVD. The systems do not require expensive and complex vacuum pumps, chambers, and pressure gauges.

Introducing vacuum requirements for LPCVD significantly increases the cost and complexity of the equipment. This includes the capital investment as well as ongoing maintenance.

Process Temperature

The references note that CVD is a high-temperature process, often exceeding 800°C. While pressure and temperature are both critical variables, using a low-pressure environment can provide a wider and more controlled processing window for achieving specific film properties.

Making the Right Choice for Your Goal

Selecting the right CVD pressure environment comes down to defining your most important outcome.

- If your primary focus is high-speed deposition and lower equipment cost: Atmospheric Pressure CVD (APCVD) is often the most appropriate and economical choice.

- If your primary focus is producing highly pure, uniform, and conformal films for sensitive applications: A low-pressure or vacuum-based CVD process is necessary to achieve the required quality.

Ultimately, pressure in CVD is not an on/off switch but a critical dial used to fine-tune the process for your specific material and performance requirements.

Summary Table:

| CVD Type | Pressure Range | Key Advantages | Ideal Applications |

|---|---|---|---|

| APCVD | Atmospheric | Fast deposition, lower equipment cost | Thick protective coatings |

| LPCVD | Low (Vacuum) | High purity, superior uniformity | Semiconductor, sensitive electronics |

Ready to optimize your CVD process? Whether you need the high-speed deposition of APCVD or the ultra-pure films from LPCVD, KINTEK has the expertise and equipment to meet your laboratory's specific requirements. Our team specializes in lab equipment and consumables, ensuring you get the right solution for your material science challenges. Contact us today to discuss your project and discover how we can enhance your research outcomes!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques