In short, vacuum hardening is not inherently "better," but it is a more advanced and precise process. It excels at producing parts with a perfectly clean surface finish and minimal distortion, which is critical for high-specification applications. Standard hardening, however, is a cost-effective and highly reliable method that provides the necessary strength and durability for the vast majority of industrial components.

The decision between vacuum and normal hardening is not about choosing a superior method, but about aligning the process with your specific requirements. Vacuum hardening is an investment in precision and surface integrity, while normal hardening is the practical choice for general-purpose strength and cost-efficiency.

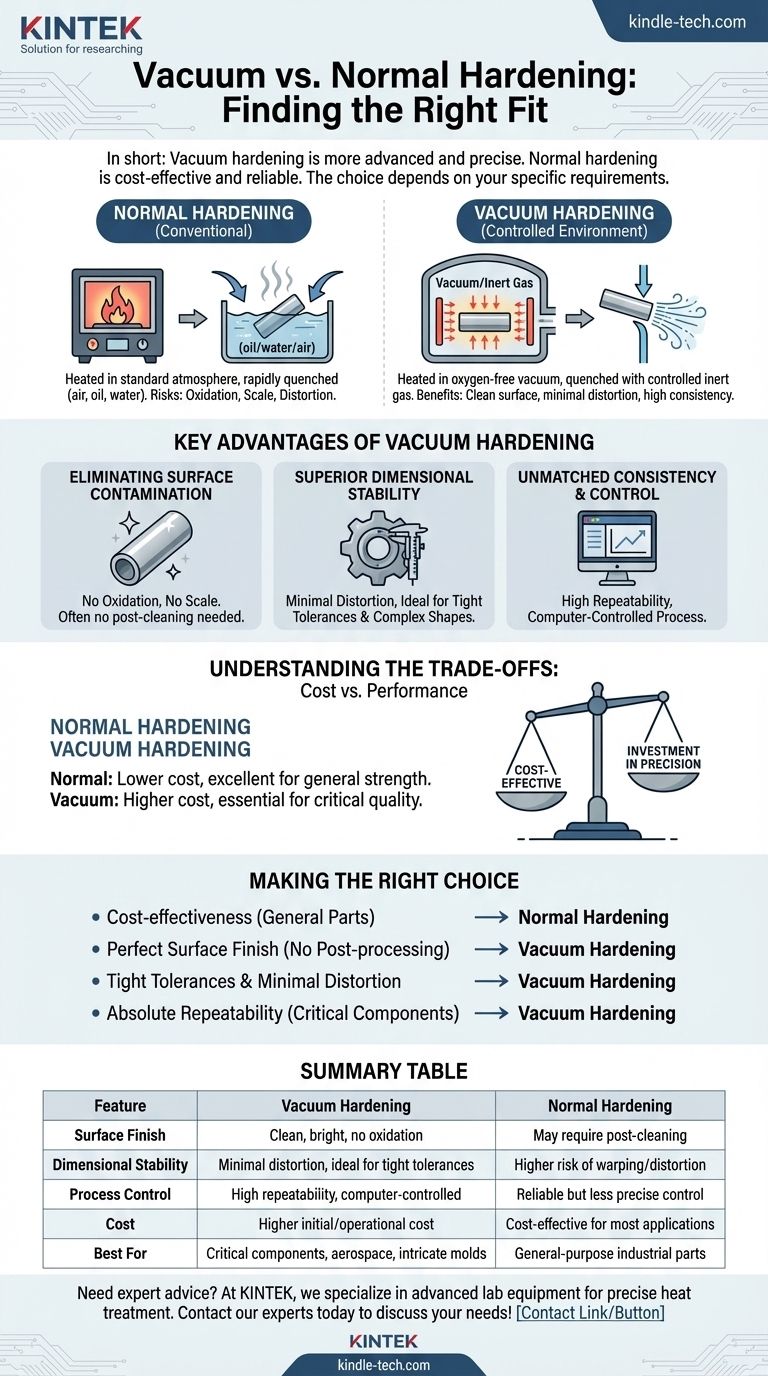

What is the Fundamental Difference in Process?

To understand the trade-offs, you must first understand the core difference in how each process works. The key distinction is the environment in which the metal is heated.

Normal Hardening: The Conventional Approach

Normal hardening is the most common form of heat treatment. A metal part is heated to a critical temperature in a furnace with a standard or controlled atmosphere. After being held at this temperature, it is rapidly cooled—or quenched—in a medium like air, oil, or water to lock in a new, harder microstructure.

Vacuum Hardening: The Controlled Environment

Vacuum hardening places the metal part inside a sealed chamber from which all air is removed, creating a vacuum. The part is then heated using convection with an inert gas (like nitrogen) or thermal radiation.

Crucially, quenching also occurs under controlled conditions, typically using a high-pressure stream of inert gas. This gives operators precise control over the cooling rate.

Key Advantages of the Vacuum Process

The controlled, oxygen-free environment of vacuum hardening provides distinct benefits that are essential for certain applications.

Eliminating Surface Contamination

Because there is no oxygen in the chamber, oxidation cannot occur. This prevents the formation of scale on the metal's surface.

The process also prevents other surface reactions like carburization or decarburization, resulting in a part that emerges from the furnace clean, bright, and free of contamination. This often eliminates the need for costly secondary cleaning operations.

Superior Dimensional Stability

The combination of uniform heating and precisely managed gas quenching significantly reduces internal stresses. This results in minimal distortion, warping, and dimensional change.

This level of stability is critical for components with complex geometries or extremely tight tolerances, such as those used in the aerospace industry or for intricate molds and dies.

Unmatched Consistency and Control

Modern vacuum furnaces are computer-controlled, allowing for extremely high process repeatability. Every parameter—from heating rate to quench pressure—is precisely regulated. This ensures that every part in a batch receives the exact same treatment, leading to highly consistent and predictable final properties.

Understanding the Trade-offs: Cost vs. Performance

The advanced capabilities of vacuum hardening come at a price, making normal hardening the right choice for many situations.

The Case for Normal Hardening: Cost-Effectiveness

Standard hardening equipment is less complex and expensive to operate. For applications where a perfect surface finish is not required and minor dimensional changes are acceptable, it delivers excellent strength and wear resistance at a much lower cost. It is the workhorse of the heat-treating industry for a reason.

The Investment in Vacuum Hardening: When it's Justified

The higher cost of vacuum hardening is an investment in quality and precision. It is justified when the component's requirements demand it.

This includes parts where post-treatment grinding or cleaning would be too costly or complex, or for critical components where any distortion could lead to failure, such as turbine blades or high-performance gears.

Making the Right Choice for Your Goal

Select the process that aligns directly with your project's most critical outcome.

- If your primary focus is cost-effectiveness for general-purpose parts: Normal hardening is the clear and logical choice.

- If your primary focus is a perfect surface finish with no post-processing: Vacuum hardening is essential to prevent oxidation and scaling.

- If your primary focus is maintaining tight tolerances and minimizing distortion: Vacuum hardening's uniform heating and controlled cooling are superior.

- If your primary focus is absolute process repeatability for critical components: The computer control of vacuum hardening provides unmatched consistency.

By understanding this distinction, you can invest in precision only when necessary, ensuring both the performance of your components and the efficiency of your budget.

Summary Table:

| Feature | Vacuum Hardening | Normal Hardening |

|---|---|---|

| Surface Finish | Clean, bright, no oxidation | May require post-cleaning for scale removal |

| Dimensional Stability | Minimal distortion, ideal for tight tolerances | Higher risk of warping/distortion |

| Process Control | High repeatability, computer-controlled | Reliable but less precise control |

| Cost | Higher initial and operational cost | Cost-effective for most applications |

| Best For | Critical components, aerospace, intricate molds | General-purpose industrial parts |

Need expert advice on selecting the right hardening process for your components? At KINTEK, we specialize in providing advanced lab equipment and consumables for precise heat treatment applications. Whether you're working on high-specification aerospace components or general industrial parts, our solutions ensure optimal performance and efficiency. Contact our experts today to discuss how we can support your laboratory's specific hardening needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the pressure for vacuum carburizing? Unlock Superior Control and Cleanliness

- What does sintering do to metal? Transform Powder into Durable, High-Performance Parts

- What role do high-temperature annealing furnaces and water quenching systems play in the post-processing of PM-HIP joints?

- What is powder sintering? A Guide to Efficient High-Performance Part Manufacturing

- What is the temperature of a kiln? It Depends on Your Process and Kiln Type

- What is the advantage of a sealed vacuum furnace? Achieve Unmatched Material Purity and Process Control

- Which heat treatment process is the most effective at hardening steel? Achieve Maximum Hardness & Durability

- What is an example of a sintered metal? Discover Self-Lubricating Bronze Bearings