At its core, magnetron sputtering works by using a magnetic field to trap electrons near a material source, known as a target. This trapping action dramatically increases the efficiency of a plasma-based process where ions bombard the target, knocking atoms loose. These ejected atoms then travel and deposit onto a substrate, forming a uniform, high-quality thin film.

The central principle is not merely the bombardment of a target with ions; it's the strategic use of a magnetic field to create a dense, self-sustaining plasma at low pressure. This magnetic confinement is the key to achieving the high deposition rates and superior film quality for which magnetron sputtering is known.

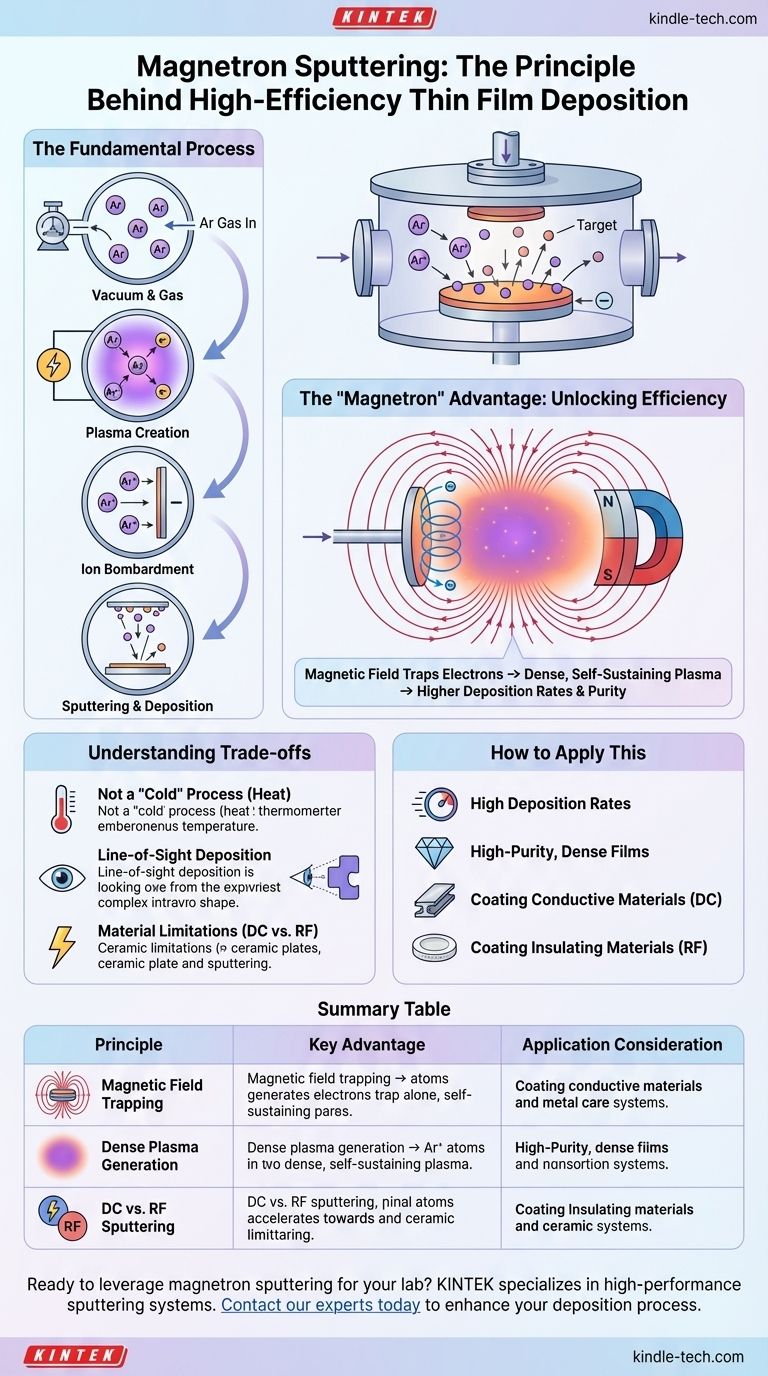

The Fundamental Process: From Plasma to Film

To understand the "magnetron" advantage, we must first understand the basic sputtering process. It occurs in a sequence of controlled steps inside a vacuum chamber.

Creating the Plasma Environment

First, the chamber is pumped down to a very low pressure (a vacuum). A small amount of an inert gas, typically Argon (Ar), is then introduced. A high negative voltage is applied to the target material, which acts as the cathode.

Ion Bombardment

The strong electric field between the negative target and the chamber (or a designated anode) energizes the environment. This energy strips electrons from some of the neutral Argon atoms, creating a mixture of positive Argon ions (Ar+) and free electrons. This ionized gas is known as a plasma.

Because opposite charges attract, the positively charged Ar+ ions are accelerated with great force directly into the negatively charged target.

The Sputtering Event

When these high-energy ions strike the target surface, they transfer their kinetic energy to the atoms of the target material. If the energy transfer is sufficient, it will overcome the binding forces of the material, ejecting or "sputtering" individual atoms from the target.

Deposition on the Substrate

These sputtered atoms are neutral and travel in a straight line through the vacuum chamber until they strike a surface. By strategically placing an object, such as a silicon wafer or optical lens, in their path, the sputtered atoms will condense on its surface, gradually building up a thin film of the target material.

The "Magnetron" Advantage: Unlocking Efficiency

Simple sputtering works, but it's inefficient. This is where the magnetron's magnetic field becomes the critical innovation.

The Role of the Magnetic Field

A set of powerful magnets is placed behind the target. This generates a magnetic field with lines of force that are perpendicular to the electric field near the target's surface.

Trapping Electrons for Maximum Impact

This magnetic field has a profound effect on the light, negatively charged electrons, especially the secondary electrons that are also knocked loose from the target during ion bombardment. Instead of escaping to the chamber walls, they are forced into a spiral path, effectively trapping them in a dense cloud directly in front of the target.

The Result: A Dense, Stable Plasma

These trapped electrons travel a much longer path and have a significantly higher probability of colliding with and ionizing neutral Argon atoms. This creates an avalanche effect, generating far more Ar+ ions than would otherwise be possible.

More Ar+ ions lead to a more intense bombardment of the target, resulting in a dramatically higher sputtering rate. This efficiency also means the process can be sustained at much lower gas pressures, which reduces the chance of gas atoms becoming incorporated into the film, thereby improving its purity and density.

Understanding the Trade-offs

While powerful, magnetron sputtering is not without its limitations. An objective assessment requires acknowledging its operational realities.

Not a "Cold" Process

The constant, intense ion bombardment generates significant heat in the target. This heat can radiate and warm the substrate, which may be a concern for temperature-sensitive materials like plastics or biological samples.

Line-of-Sight Deposition

Sputtered atoms travel in straight lines. This means that complex, three-dimensional objects can be challenging to coat uniformly without sophisticated substrate rotation and manipulation systems to ensure all surfaces are exposed to the atomic flux.

Material Limitations (DC vs. RF)

The standard method, DC magnetron sputtering, works exceptionally well for electrically conductive targets like metals. However, if the target is an insulator (like a ceramic), the positive ion bombardment will cause a positive charge to build up on its surface, eventually repelling further ions and stopping the process. For these materials, RF (Radio Frequency) sputtering is required, which uses an alternating electric field to prevent this charge accumulation.

How to Apply This to Your Project

Understanding this principle helps you decide if magnetron sputtering aligns with your project goals.

- If your primary focus is high deposition rates and efficiency: Magnetron sputtering is ideal because its magnetic confinement creates a dense plasma that dramatically increases the sputtering rate over other methods.

- If your primary focus is high-purity, dense films: The ability to operate at lower pressures, thanks to the efficient plasma, reduces gas incorporation and leads to higher-quality coatings with superior structural and optical properties.

- If your primary focus is coating conductive materials: Standard DC magnetron sputtering is a cost-effective, reliable, and highly controlled method for depositing metals and other conductive layers.

- If your primary focus is coating insulating or ceramic materials: You must specify RF (Radio Frequency) magnetron sputtering, which is specifically designed to handle non-conductive targets without process-halting charge buildup.

By mastering these principles, you can effectively leverage magnetron sputtering to achieve precise and high-quality thin-film coatings for your application.

Summary Table:

| Principle | Key Advantage | Application Consideration |

|---|---|---|

| Magnetic Field Trapping | High deposition rate & efficiency | Ideal for high-throughput coating |

| Dense Plasma Generation | Superior film purity & density | Excellent for optical & electronic layers |

| DC vs. RF Sputtering | Versatility for conductive/insulating materials | Choose based on target material conductivity |

Ready to leverage magnetron sputtering for your laboratory's thin film needs? KINTEK specializes in high-performance lab equipment, including sputtering systems, to help you achieve precise, high-quality coatings for research and production. Our expertise ensures you get the right solution for conductive metals, ceramics, and other materials. Contact our experts today to discuss how we can enhance your deposition process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is the importance of a magnetic stirrer in electrochemical acrylic acid degradation? Optimize Mass Transfer

- Why is a laboratory magnetic stirrer required for benzoic acid esters? Boost Reaction Speed & Yield with High RPM

- What type of samples can be characterized with IR spectroscopy? Analyze Solids, Liquids, and Gases

- How much electricity does an arc furnace use? The Immense Power Behind Modern Steelmaking

- What types of metals can be used in sintering? Expert Guide to Sintered Alloys and Non-Ferrous Metals

- How is thin film thickness measured? Achieve Atomic-Level Precision for Your Films

- What is the annealing process in industry? A Guide to Relieving Stress and Restoring Ductility

- How much energy does a filter press use? The Real Power Draw is the Feed Pump