At its core, the primary apparatus used in pyrolysis is a specialized high-temperature reactor. The most common types for processing materials like biomass are rotary kiln reactors and fluidized bed reactors, each designed to heat material in an oxygen-free environment to induce thermal decomposition. The specific design of the reactor is chosen based on the feedstock and the desired end products.

The choice of pyrolysis apparatus is not just about containing a reaction; it is the critical tool that dictates the process conditions—like heating rate and time—and therefore determines whether the primary output will be liquid bio-oil, solid biochar, or combustible gas.

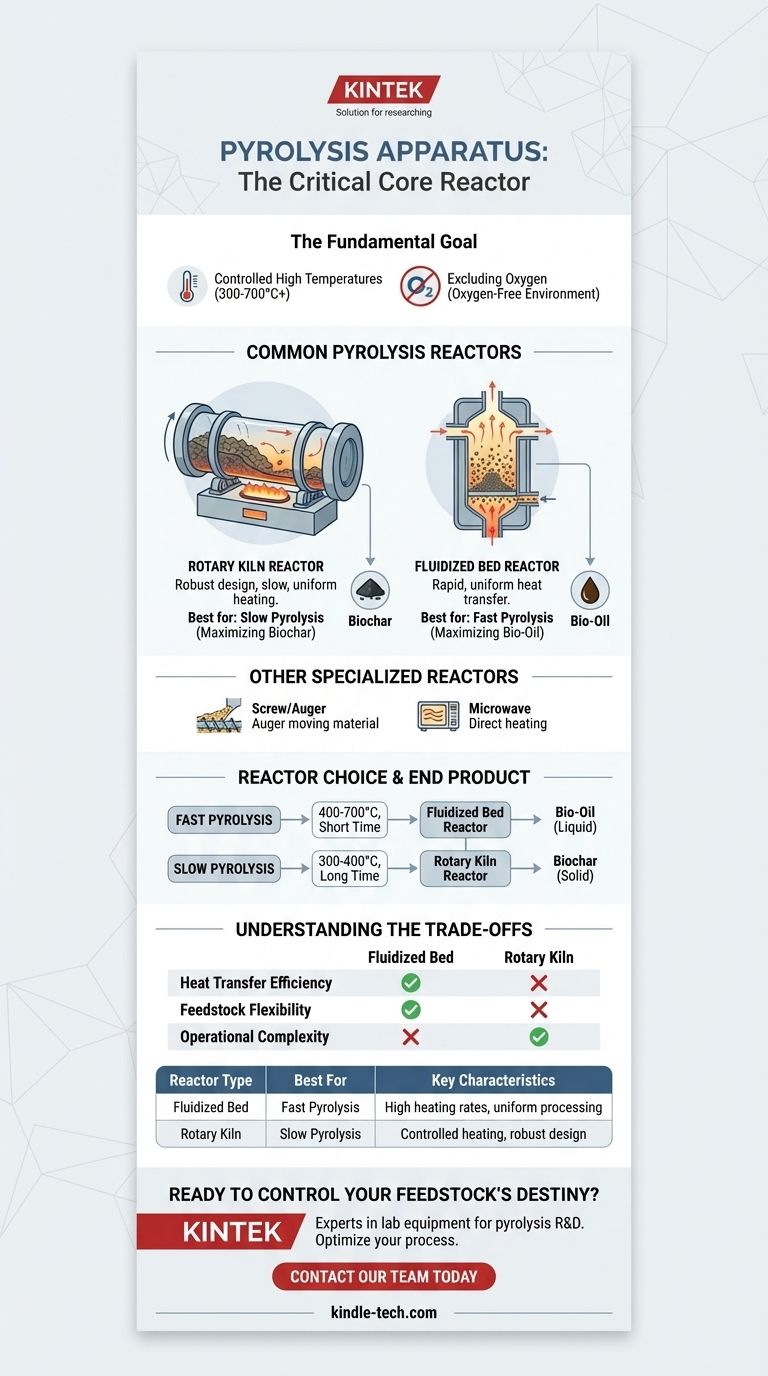

The Fundamental Goal of a Pyrolysis Reactor

Every pyrolysis reactor, regardless of its specific design, must accomplish two primary objectives to successfully decompose organic material.

Achieving Controlled High Temperatures

The apparatus must be capable of heating feedstock to temperatures typically ranging from 300°C to over 700°C. This thermal energy is what breaks down the complex chemical bonds within the material.

Excluding Oxygen

Crucially, this heating must occur in an environment with little to no oxygen. The presence of oxygen would cause combustion (burning), whereas its absence ensures the material undergoes pyrolysis, breaking down into different valuable components.

Common Types of Pyrolysis Reactors

While many designs exist, two types dominate industrial and research applications due to their efficiency and scalability.

Rotary Kiln Reactors

A rotary kiln is a large, rotating cylindrical vessel. Feedstock is fed into one end, and as the cylinder slowly rotates, the material tumbles and moves toward the other end, ensuring it is heated evenly.

This design is robust and excellent for processes requiring longer residence times and slower, more controlled heating.

Fluidized Bed Reactors

In a fluidized bed reactor, a stream of hot gas is passed up through the particulate feedstock at a high enough velocity to suspend the particles. The material behaves like a fluid, allowing for extremely rapid and uniform heat transfer.

This characteristic makes fluidized bed reactors ideal for processes that demand very fast heating rates.

Other Specialized Reactors

Less common but effective for specific applications are screw pyrolysis reactors (using an auger to move material through a heated chamber) and microwave pyrolysis reactors (using microwaves for direct, targeted heating).

How Reactor Choice Defines the End Product

The type of reactor is selected to facilitate a specific type of pyrolysis, which in turn maximizes the yield of a desired product.

For Maximizing Bio-Oil (Fast Pyrolysis)

To produce liquid bio-oil, fast pyrolysis is required. This process involves heating the biomass to 400-700°C very quickly with a short residence time.

Fluidized bed reactors excel at this, as their exceptional heat transfer capabilities can bring the material to the target temperature almost instantly.

For Maximizing Biochar (Slow Pyrolysis)

To produce solid biochar, slow pyrolysis is the preferred method. This involves heating biomass at lower temperatures (300-400°C) over a much longer period.

Rotary kiln reactors are well-suited for this, as their slow, tumbling action allows for prolonged and controlled exposure to heat, optimizing the conversion to stable carbon char.

Understanding the Trade-offs

Choosing a reactor involves balancing efficiency, cost, and operational requirements.

Heat Transfer Efficiency

Fluidized bed reactors offer superior heat transfer, leading to more uniform processing and faster reaction rates, which is critical for fast pyrolysis. Rotary kilns can have less efficient heat transfer by comparison.

Feedstock Flexibility

Fluidized bed reactors can often handle a wider variety of feedstock sizes and types without extensive pre-treatment. Rotary kilns may be more sensitive to the physical properties of the input material.

Operational Complexity

Rotary kilns are generally simpler mechanically and can be more robust and easier to maintain. Fluidized bed systems are more complex due to the need for precise gas flow control to maintain fluidization.

Making the Right Choice for Your Goal

The selection of a pyrolysis apparatus is fundamentally a strategic decision driven by the desired outcome.

- If your primary focus is maximizing liquid bio-oil yield: A reactor capable of very high heating rates, such as a fluidized bed reactor, is the industry standard.

- If your primary focus is producing high-quality solid biochar: A reactor that allows for slow, controlled heating and long residence times, like a rotary kiln, is the more effective choice.

Ultimately, the reactor is the instrument that allows you to precisely control the chemical destiny of your feedstock.

Summary Table:

| Reactor Type | Best For | Key Characteristics |

|---|---|---|

| Fluidized Bed | Fast Pyrolysis (Maximizing Bio-Oil) | Very high heating rates, excellent heat transfer, uniform processing. |

| Rotary Kiln | Slow Pyrolysis (Maximizing Bio-Char) | Slow, controlled heating, long residence times, robust design. |

| Screw / Auger | Specific Feedstocks | Uses an auger to move material through a heated chamber. |

| Microwave | Specialized Applications | Uses microwave energy for direct, targeted heating. |

Ready to control the chemical destiny of your feedstock?

Choosing the right pyrolysis apparatus is critical to achieving your target product yields. The experts at KINTEK specialize in lab equipment for pyrolysis research and development, helping you select the perfect reactor system for your specific biomass and goals.

Contact our team today to discuss your project and discover how KINTEK's solutions can optimize your pyrolysis process for maximum efficiency and output.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products