In short, ceramic tubes are used where other materials would fail due to extreme heat, electrical voltage, or chemical attack. They serve as protective sheaths, structural components, and insulators in the most demanding industrial and laboratory environments, most notably in furnaces and kilns.

The core reason for using a ceramic tube is its ability to maintain structural integrity, chemical inertness, and electrical insulation at temperatures that would melt or compromise most metals and plastics.

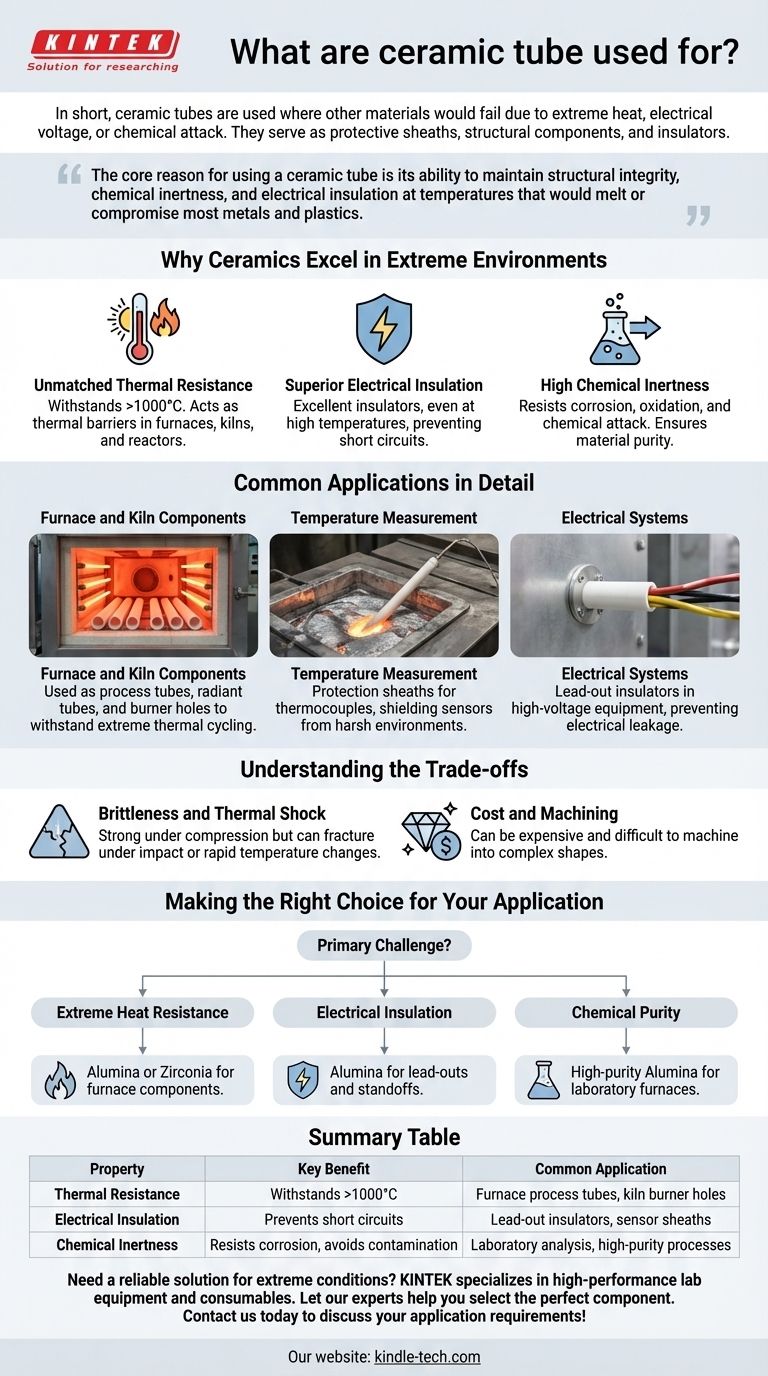

Why Ceramics Excel in Extreme Environments

The applications for ceramic tubes are driven by a unique set of material properties. Understanding these properties is key to understanding their role in high-performance systems.

Unmatched Thermal Resistance

Ceramic materials possess exceptionally high melting points and low thermal conductivity.

This allows them to act as thermal barriers or structural elements inside furnaces, kilns, and reactors operating at temperatures well over 1000°C (1832°F).

Superior Electrical Insulation

Unlike metals, most ceramics are excellent electrical insulators, even at elevated temperatures.

This property is critical for applications that involve passing high-voltage electrical wires into or out of a heated or controlled environment without creating a short circuit.

High Chemical Inertness

Ceramics are highly resistant to corrosion, oxidation, and chemical attack from acids, bases, and molten materials.

This makes them essential for laboratory analysis and industrial processes where material purity is paramount and contamination from the container itself must be avoided.

Common Applications in Detail

These core properties translate directly into specific, critical industrial uses. Each application leverages one or more of these strengths.

Furnace and Kiln Components

This is the most common application. Ceramic tubes are used as process tubes, holding materials being heated, or as radiant tubes, protecting heating elements from the furnace atmosphere.

They are also used to form burner holes in gas and oil-fired kilns, where they must withstand direct flame impingement and extreme thermal cycling.

Temperature Measurement

Ceramic tubes are widely used as protection sheaths for thermocouples and other temperature sensors.

The tube shields the sensitive sensor from the harsh furnace environment (e.g., molten metal, corrosive gases) without interfering with an accurate temperature reading.

Electrical Systems

In high-temperature or high-voltage equipment, ceramic tubes serve as lead-out insulators.

They allow electrical conductors to pass safely through a furnace wall or equipment housing, preventing electrical energy from leaking to the chassis.

Understanding the Trade-offs

While exceptionally capable, ceramics are not a universal solution. Their unique properties come with important considerations.

Brittleness and Thermal Shock

The primary drawback of most ceramics is their brittleness. They are strong under compression but can fracture easily under impact or tensile stress.

Additionally, rapid temperature changes (thermal shock) can cause some ceramics to crack. Proper material selection and gradual heating and cooling cycles are essential.

Cost and Machining

Advanced ceramic materials can be more expensive than specialty metals.

They are also extremely hard, which makes them difficult and costly to machine into complex shapes after they have been fired.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to overcome.

- If your primary focus is extreme heat resistance: Alumina or Zirconia ceramic tubes are the superior choice for furnace components and sensor protection.

- If your primary focus is electrical insulation at high temperatures: Alumina is an industry standard for lead-outs and electrical standoffs.

- If your primary focus is chemical purity and inertness: High-purity Alumina is essential for laboratory furnaces and analytical equipment.

Ultimately, choosing a ceramic tube is a decision to prioritize performance and reliability in conditions where conventional materials are guaranteed to fail.

Summary Table:

| Property | Key Benefit | Common Application |

|---|---|---|

| Thermal Resistance | Withstands temperatures >1000°C | Furnace process tubes, kiln burner holes |

| Electrical Insulation | Prevents short circuits at high voltage | Lead-out insulators, sensor sheaths |

| Chemical Inertness | Resists corrosion and avoids contamination | Laboratory analysis, high-purity processes |

Need a reliable solution for extreme conditions? KINTEK specializes in high-performance lab equipment and consumables, including ceramic tubes designed for superior thermal management, electrical insulation, and chemical resistance. Let our experts help you select the perfect component for your furnace, kiln, or high-temperature system. Contact us today to discuss your application requirements!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- Laboratory High Pressure Vacuum Tube Furnace

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- Why is a differential tube reactor utilized for annealing experiments? Achieve High-Precision Iron Nitride Phase Control

- What are the advantages of using a vertical tube furnace for dynamic corrosion testing? Precision Meets Geometry

- What material are furnace tubes? Choosing the Right Material for High-Temperature Success

- What are the advantages of using a horizontal tube furnace with quartz for FeCrAl oxidation? Ensure Purity and Precision

- What functions does a laboratory high-temperature tube furnace perform? Master Catalyst Synthesis & Carbonization

- What are the primary functions of a high-temperature tube furnace in TB8 titanium alloy hydrogen charging experiments?

- What is a split tube furnace? Unlock Unmatched Access for Complex Lab Setups

- What is a tube furnace used for? Precision Heating for Material Synthesis & Analysis