In essence, ceramic tubes are used in applications where extreme heat, electrical voltage, or corrosive environments would cause other materials like metal or plastic to fail. Their primary roles are found in industrial furnaces, kilns, and specialized laboratory equipment for tasks that require structural integrity and insulation at incredibly high temperatures.

The core reason for using ceramic tubes is their exceptional stability in hostile environments. While metals warp and plastics melt, technical ceramics maintain their shape, electrical insulation, and chemical purity at extreme temperatures, making them the default material for the most demanding industrial and scientific processes.

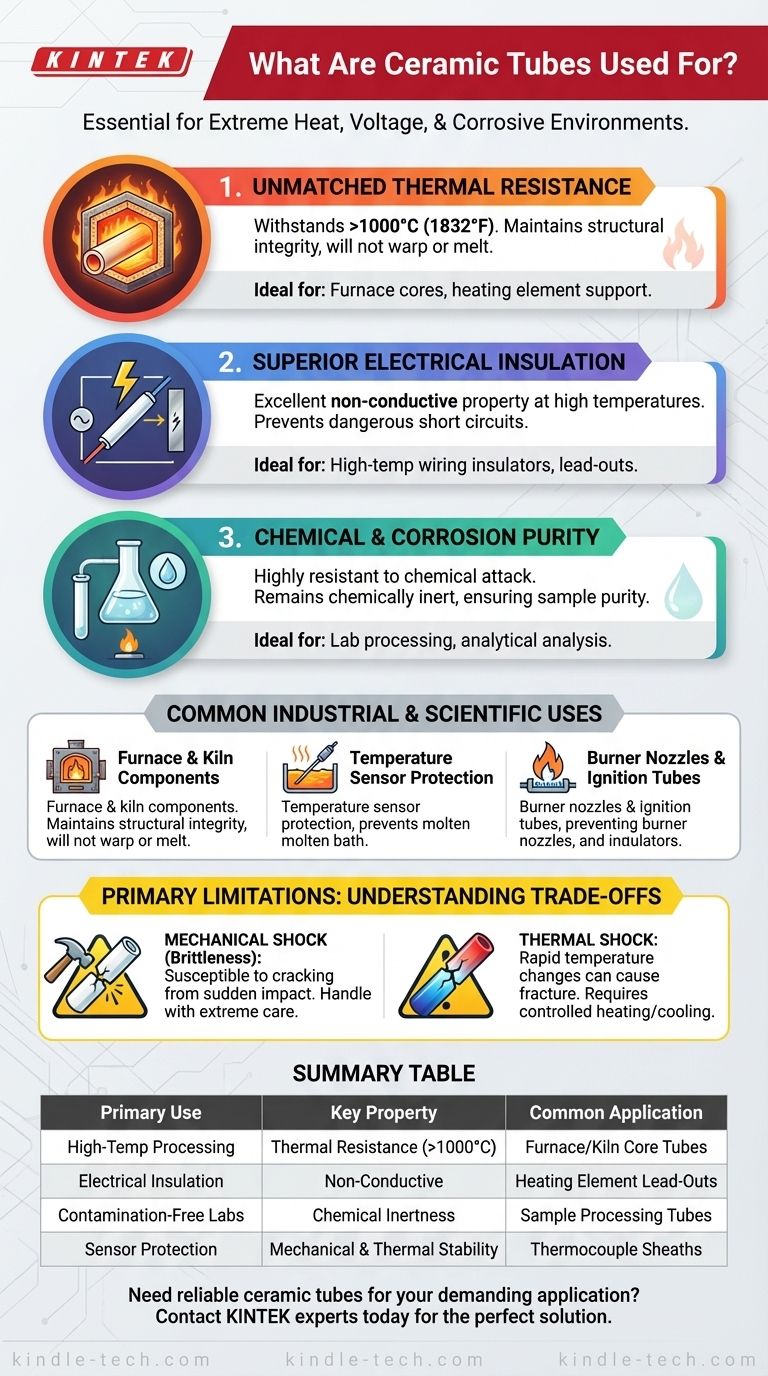

Why Ceramics are Essential in Demanding Environments

The unique properties of technical ceramics are what define their uses. They solve problems that are impossible to address with metals or polymers alone.

Unmatched Thermal Resistance

The most common application for ceramic tubes is inside furnaces and kilns. They can withstand continuous operating temperatures well over 1000°C (1832°F) without melting, warping, or degrading.

This makes them ideal for constructing the core of a furnace, supporting heating elements, or containing a process that requires intense, direct heat.

Superior Electrical Insulation

Unlike metals, ceramics are excellent electrical insulators. This property is critical in high-temperature electrical applications.

They are used as lead-outs or insulators for electrical wiring inside furnaces. A plastic insulator would instantly melt, while a ceramic tube ensures electricity flows only where it is intended, preventing dangerous short circuits.

Chemical and Corrosion Purity

Ceramic tubes are highly resistant to chemical attack and corrosion, even at high temperatures. This is vital in laboratory and analytical settings.

When a sample must be heated without contamination, it is often placed inside a ceramic tube. The tube remains inert, ensuring the purity of the material being analyzed or processed.

Common Industrial and Scientific Uses

These fundamental properties translate into several key applications across various fields.

Furnace and Kiln Components

Ceramic tubes often form the structural heart of electric laboratory and production furnaces. Heating elements are wound around or placed inside them, allowing for stable and uniform heat generation.

Temperature Measurement Protection

Sensitive temperature sensors, such as thermocouples, need protection from the harsh environments they are meant to measure.

A ceramic tube acts as a protective sheath, allowing the thermocouple to be inserted directly into a furnace or molten metal bath. The sheath shields the delicate wires from corrosion and physical damage while accurately transferring thermal energy for a correct reading.

Burner Nozzles and Ignition Tubes

In gas and oil-fired equipment, ceramic tubes are used as burner nozzles or pilot light protectors. They can withstand direct flame impingement without degrading, ensuring reliable and safe combustion.

Understanding the Primary Limitation: Brittleness

To use ceramic tubes effectively, it is crucial to understand their primary trade-off. While exceptionally strong under compression and heat, they are not ductile like metals.

Susceptibility to Mechanical Shock

Ceramics are brittle, meaning they can crack or shatter if subjected to a sudden impact, such as being dropped or struck. Careful handling during installation and operation is non-negotiable.

Managing Thermal Shock

While designed for high heat, a rapid and uneven change in temperature—known as thermal shock—can cause a ceramic tube to fracture. Pre-heating cycles and controlled cooling rates are often necessary to manage this stress and ensure a long service life.

How to Apply This to Your Project

Your specific goal will determine how you leverage the properties of ceramic tubes.

- If your primary focus is extreme heat processing: A ceramic furnace tube is the essential component for providing the structural stability needed for the core heating chamber.

- If your primary focus is high-voltage insulation in a hot environment: Ceramic insulators are the only reliable option to prevent electrical failure where plastics would melt and metals would conduct.

- If your primary focus is maintaining chemical purity in a lab: The inert nature of a ceramic processing tube ensures your sample is not contaminated during high-temperature analysis.

Ultimately, choosing a ceramic tube is a decision to prioritize stability and reliability in conditions where conventional materials simply cannot perform.

Summary Table:

| Primary Use | Key Property | Common Application |

|---|---|---|

| High-Temperature Processing | Thermal Resistance (>1000°C) | Furnace/Kiln Core Tubes |

| Electrical Insulation | Non-Conductive | Heating Element Lead-Outs |

| Contamination-Free Labs | Chemical Inertness | Sample Processing Tubes |

| Sensor Protection | Mechanical & Thermal Stability | Thermocouple Sheaths |

Need a reliable ceramic tube for your demanding application? KINTEK specializes in high-performance lab equipment and consumables, including ceramic tubes designed for extreme environments. Our products ensure precise temperature control, superior insulation, and contamination-free processing for your laboratory. Contact our experts today to find the perfect solution for your project!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- How do alumina ceramic tubes address technical challenges in electrochemical devices? Ensure Peak Signal Integrity.

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- How to decrease porosity in aluminum oxide? Master Powder & Sintering for Maximum Density

- What is the strength of dental ceramics? Mastering the Compressive vs. Tensile Force Balance

- What is the new technology for veneers? Discover the Digital Revolution for a Perfect Smile

- Are ceramics biocompatible? Choosing the Right Bioceramic for Your Medical Application

- What are the disadvantages of ceramics? Understanding Brittleness, Cost, and Design Challenges

- What is the strongest zirconia phase? Tetragonal Zirconia Offers Unmatched Toughness