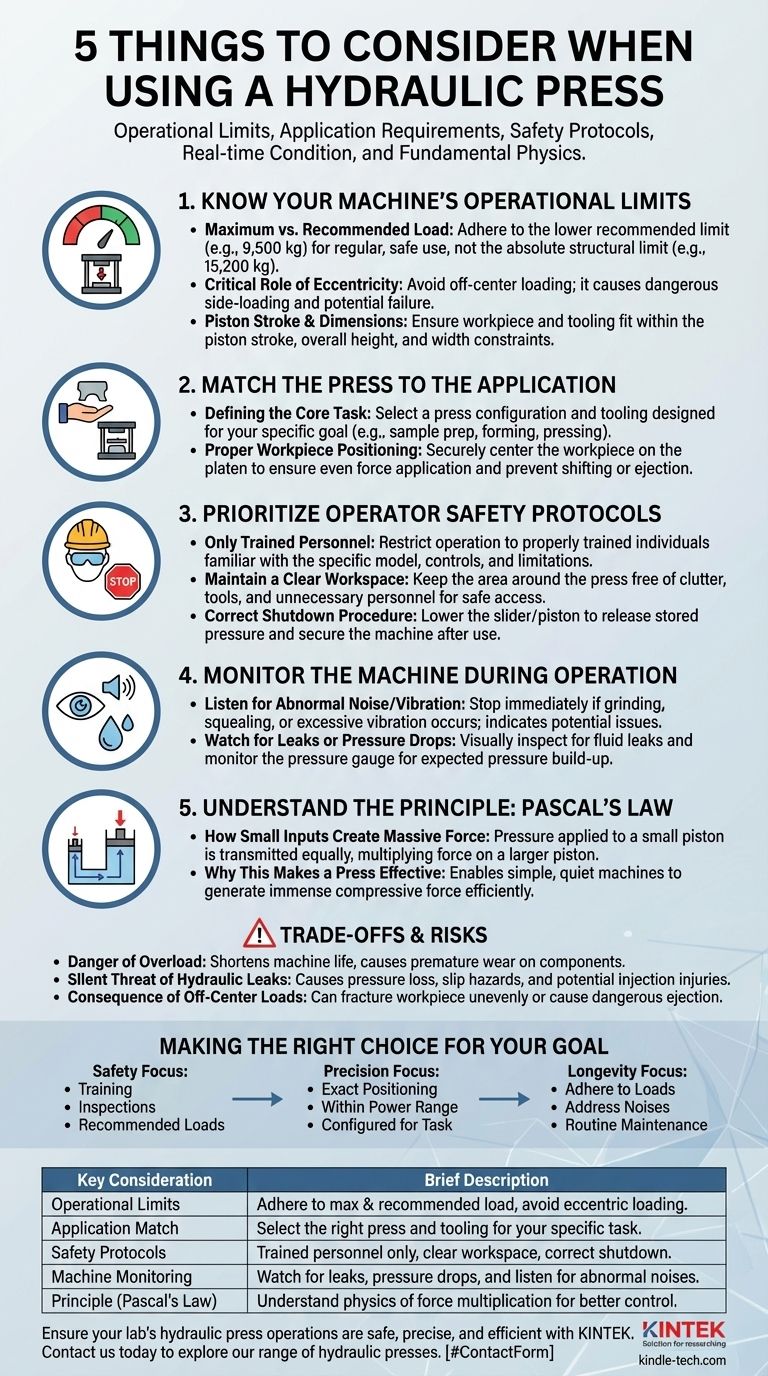

Before using a hydraulic press, you must consider five key factors: the machine's specific operational limits, the requirements of your application and workpiece, strict safety protocols, the real-time condition of the machine during use, and the fundamental physics that gives the press its power. Understanding these elements is essential for ensuring both the safety of the operator and the accuracy of the work.

A hydraulic press is a study in contrasts: its design is simple, yet the force it generates is immense. True mastery comes not just from following steps, but from deeply respecting the machine's capabilities, its limitations, and the signs it gives you during operation.

1. Know Your Machine's Operational Limits

Every hydraulic press has a defined performance envelope. Operating outside of it invites failure and risk.

Maximum vs. Recommended Load

A press often has two critical force ratings. The maximum allowed power is the absolute structural limit, while the maximum recommended power is the upper limit for continuous, safe, and accurate use. For example, a press might be rated for a 15,200 kg maximum but only recommended for 9,500 kg for regular operations. Always adhere to the recommended limit for longevity and safety.

The Critical Role of Eccentricity

Eccentricity refers to off-center loading. Presses are designed for force to be applied evenly across the piston and platen. Applying a load off-center can create dangerous side-loading on the piston and frame, potentially damaging the machine or causing catastrophic failure, even at pressures below the maximum rating.

Piston Stroke and Physical Dimensions

The piston stroke is the maximum distance the piston can travel. This, along with the press's overall height and width, dictates the maximum size of the workpiece you can physically fit and work on. Always ensure your workpiece and any required tooling fit comfortably within these physical constraints.

2. Match the Press to the Application

A press is a tool, and using the right tool for the job is paramount. This starts with understanding your goal and how the workpiece interacts with the machine.

Defining the Core Task

Are you preparing a sample pellet for a lab, forming a metal part, or pressing a bearing? Each application has different requirements for force, precision, and tooling. Selecting a press configuration designed for your specific task is the first step toward accurate results.

Proper Workpiece Positioning

The workpiece must be positioned securely and, in most cases, centrally on the platen. This ensures the force is applied as intended and prevents the workpiece from shifting or being ejected under pressure. Careful positioning is a fundamental requirement for both safety and quality.

3. Prioritize Operator Safety Protocols

The immense force generated by a hydraulic press demands unwavering adherence to safety procedures. Complacency is the biggest risk.

Only Trained Personnel

Only individuals who have been properly trained on the specific model of press should operate it. This training must cover its controls, emergency stop procedures, and its specific limitations.

Maintain a Clear Workspace

The area around the hydraulic press must be kept clear of all clutter, tools, and unnecessary personnel. This ensures the operator has unimpeded access and a safe zone in case of any malfunction.

Correct Shutdown Procedure

When work is complete, the machine should be properly shut down. This often includes lowering the slider or piston to its lowest position to release any stored hydraulic pressure and secure the machine.

Understanding the Trade-offs and Risks

While powerful and efficient, a hydraulic press has inherent risks that must be managed through knowledge and vigilance.

The Danger of Overload

Many modern presses have built-in overload protection, but this should be considered a last-resort safety feature, not a working limit. Intentionally pushing a press to its overload point can cause premature wear on seals, the frame, and hydraulic components, shortening the machine's life.

The Silent Threat of Hydraulic Leaks

A leak is more than just a mess. A serious oil leak can cause a sudden loss of pressure, potentially dropping the load unexpectedly. Furthermore, high-pressure hydraulic fluid can be a slip hazard or, in a worst-case scenario, cause severe injection injuries if it penetrates the skin.

The Consequence of Off-Center Loads

Revisiting eccentricity from a risk perspective, an off-center load doesn't just strain the press; it can cause the workpiece to fracture unevenly or be ejected from the press at high velocity.

4. Monitor the Machine During Operation

A press communicates its health through sight and sound. An attentive operator is the best form of real-time diagnostics.

Listen for Abnormal Noise or Vibration

Grinding, squealing, or excessive vibration are clear indicators of a problem. These sounds can point to air in the hydraulic lines, component misalignment, or imminent mechanical failure. If you hear anything unusual, stop the press immediately.

Watch for Leaks or Pressure Drops

Visually inspect the machine during operation for any signs of leaking fluid. Likewise, keep an eye on the pressure gauge. If the pressure fails to build as expected or drops without input, there is a fault in the hydraulic system that must be investigated and resolved.

5. Understand the Principle: Pascal's Law

To truly respect the machine, you must understand where its power comes from. A hydraulic press operates on Pascal's Law, which states that pressure applied to a confined fluid is transmitted equally in all directions.

How Small Inputs Create Massive Force

The press uses a small piston to apply pressure to hydraulic fluid. This pressure is then transmitted to a much larger piston, which multiplies the force significantly. This principle allows a small, manageable input to generate the immense compressive force the press is known for.

Why This Makes a Press So Effective

This force multiplication is what makes hydraulics so efficient and adaptable. It allows for a relatively simple, small, and quiet machine to perform work that would otherwise require massive and complex mechanical gears and levers. Recognizing this principle helps you appreciate the stored energy you are controlling.

Making the Right Choice for Your Goal

Your primary objective dictates which considerations you must emphasize.

- If your primary focus is operator safety: Your non-negotiable checklist is operator training, pre-use inspection for leaks or damage, and never exceeding recommended load limits.

- If your primary focus is precision and accuracy: You must concentrate on exact workpiece positioning, operating well within the press's recommended power range for consistency, and ensuring the press is configured for your specific application.

- If your primary focus is equipment longevity: Adhering strictly to recommended loads, addressing abnormal noise or vibration immediately, and performing routine maintenance to prevent leaks are your top priorities.

By treating the hydraulic press as the precise and powerful tool it is, you ensure safety, accuracy, and efficiency in every operation.

Summary Table:

| Key Consideration | Brief Description |

|---|---|

| Operational Limits | Adhere to maximum and recommended load ratings, avoid eccentric loading. |

| Application Match | Select the right press and tooling for your specific task and workpiece. |

| Safety Protocols | Ensure only trained personnel operate the press; maintain a clear workspace. |

| Machine Monitoring | Watch for leaks, pressure drops, and listen for abnormal noises during use. |

| Principle (Pascal's Law) | Understand the physics of force multiplication for better control and safety. |

Ensure your lab's hydraulic press operations are safe, precise, and efficient with KINTEK.

As a trusted supplier of lab equipment and consumables, KINTEK specializes in providing reliable hydraulic presses and expert guidance tailored to your laboratory needs. Whether you're preparing samples, forming materials, or conducting research, our equipment is designed for durability, accuracy, and operator safety.

Contact us today to explore our range of hydraulic presses and discover how we can support your lab's success. Let’s enhance your productivity together!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is the purpose of using laboratory hydraulic presses for molecular sieve catalysts? Optimize Reactor Performance

- What are the disadvantages of KBr pellets? Avoid Moisture & Prep Errors in FTIR Analysis

- Why is hydraulic oil bad for the environment? The Hidden Dangers of Petroleum-Based Fluids

- What are two problems that could arise in the preparation of a KBr pellet for IR analysis? Avoid Moisture & Grinding Errors

- What is the role of a laboratory hydraulic press in molecular sieve catalyst preparation? Achieve Optimal Pelleting

- What material can withstand a hydraulic press? Understanding Compressive Strength vs. Pressure

- What is pressed pellets? Transform Powders into Reliable Solid Samples for Analysis

- What is the purpose of using a laboratory hydraulic press for nanocomposites? Ensure Precise Material Characterization