In essence, powder sintering is a manufacturing process that transforms metallic or ceramic powders into a solid, coherent object. It achieves this by applying heat to a pre-formed shape, bringing the temperature high enough to bond the powder particles together but staying just below the material's melting point. This atomic-level fusion is what gives the final part its strength and density.

The core principle of sintering is simple: you don't need to melt a material to make it solid. By carefully controlling heat and sometimes pressure, you can fuse individual powder particles into a strong, functional component, offering a powerful alternative to traditional casting or machining.

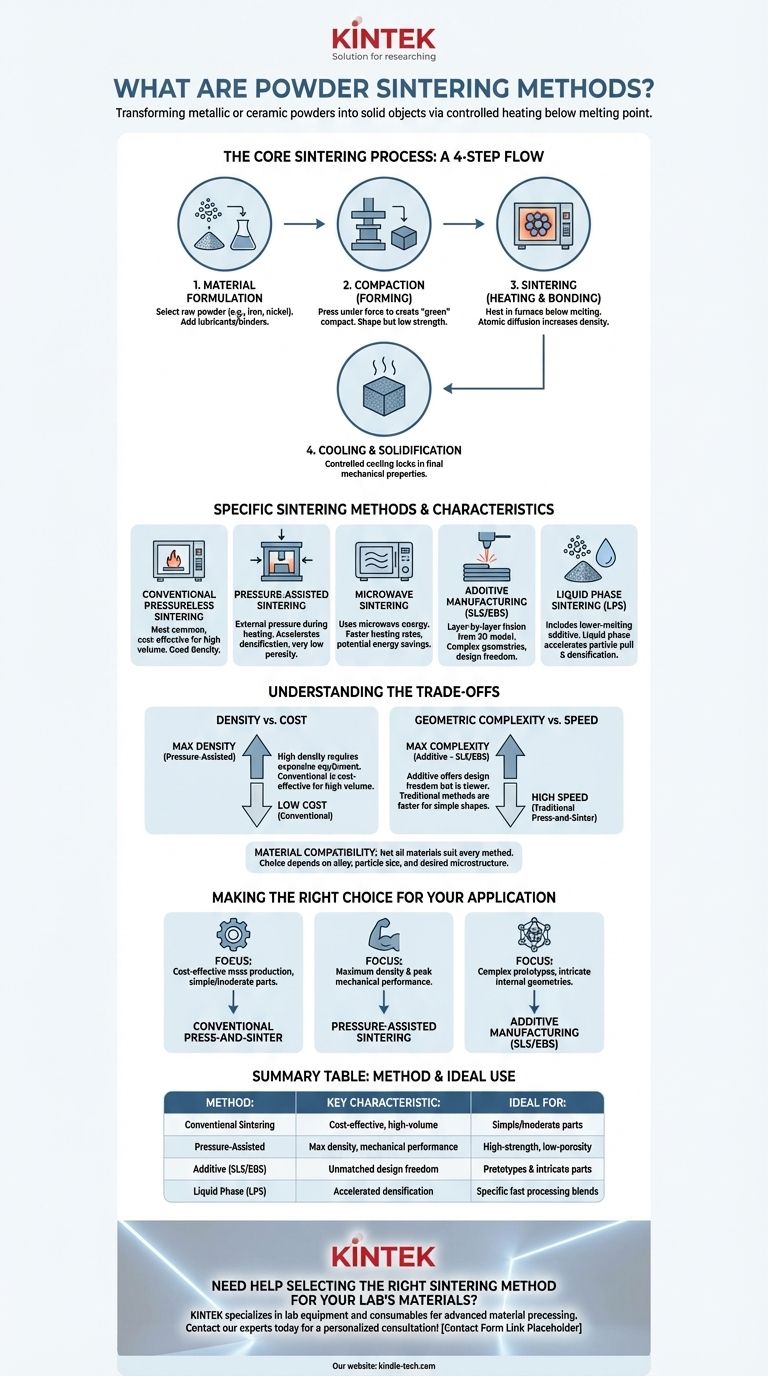

The Core Sintering Process: A Step-by-Step Breakdown

Nearly all sintering methods are built upon a fundamental, multi-stage process. Understanding this core sequence is key to grasping how more specialized techniques work.

Step 1: Material Formulation

The process begins by selecting and preparing the raw powder. The choice of metal—such as iron, nickel, copper, or molybdenum—directly dictates the final properties of the component.

Often, lubricants or binding agents are mixed in to improve how the powder flows and compacts in the next stage.

Step 2: Compaction (Forming the "Green" Part)

The prepared powder mix is loaded into a die and compressed under significant force. This is the most common method of pressurized forming.

This step creates a fragile, pre-sintered object known as a "green" compact. It has the desired shape but lacks the final strength and hardness of the finished part.

Step 3: Sintering (Heating and Bonding)

The green part is moved into a controlled-atmosphere furnace and heated. The temperature is raised to just below the material's melting point.

At this high temperature, atomic diffusion accelerates. Particles begin to merge at their contact points through mechanisms like grain boundary diffusion and surface diffusion, reducing porosity and increasing the part's density.

Step 4: Cooling and Solidification

After being held at the sintering temperature for a set time, the component is cooled in a controlled manner. This allows it to solidify into a single, unified mass with its final mechanical properties locked in.

A Closer Look at Specific Sintering Methods

While the core process is consistent, several distinct methods have been developed to optimize for different materials, densities, and applications.

Conventional Pressureless Sintering

This is the most common and straightforward method, following the exact four-step process described above. It is highly effective for mass production of parts where ultra-high density is not the primary requirement.

Pressure-Assisted Sintering

This category of methods applies external pressure during the heating phase. The combined force and heat dramatically accelerate densification, resulting in parts with very low porosity and superior mechanical properties.

Microwave Sintering

Instead of a conventional furnace, this technique uses microwave energy to heat the material. This can lead to much faster heating rates and potentially lower energy consumption, making it an area of active development.

Additive Manufacturing Methods (SLS & EBS)

Techniques like Selective Laser Sintering (SLS) and Electron Beam Sintering (EBS) are revolutionary. They use a high-energy beam to sinter powdered material layer by layer directly from a 3D model.

These methods effectively combine the compaction and sintering steps, allowing for the creation of extremely complex geometries that are impossible to produce with traditional die compaction.

Liquid Phase Sintering (LPS)

LPS is a variation where the powder blend includes a secondary material with a lower melting point. During heating, this secondary material melts, creating a liquid phase that pulls the primary solid particles together more quickly and effectively through capillary action, accelerating densification.

Understanding the Trade-offs

Choosing a sintering method requires balancing competing priorities. No single technique is universally superior; the optimal choice depends entirely on the project's goals.

Density vs. Cost

Methods like pressure-assisted sintering produce exceptionally dense parts but require more complex and expensive equipment. Conventional sintering is more cost-effective for high-volume production where good, but not perfect, density is acceptable.

Geometric Complexity vs. Speed

Additive methods like SLS offer unparalleled design freedom for creating intricate parts. However, for producing thousands of relatively simple shapes, traditional press-and-sinter is significantly faster and cheaper.

Material Compatibility

Not all materials respond equally to every method. The specific alloy, particle size, and desired final microstructure can make a material well-suited for one technique but difficult to process with another.

Making the Right Choice for Your Application

Your final goal should guide your choice of sintering method.

- If your primary focus is cost-effective mass production of simple to moderately complex parts: Conventional press-and-sinter is the industry standard for a reason.

- If your primary focus is achieving maximum density and peak mechanical performance: Pressure-assisted sintering is the most direct path to creating near-fully dense components.

- If your primary focus is creating complex prototypes or parts with intricate internal geometries: Additive manufacturing methods like SLS or EBS provide unmatched design freedom.

Understanding these distinct pathways empowers you to select the precise manufacturing process to achieve your desired material properties with optimal efficiency.

Summary Table:

| Method | Key Characteristic | Ideal For |

|---|---|---|

| Conventional Sintering | Cost-effective, high-volume production | Simple to moderately complex parts |

| Pressure-Assisted | Maximum density & mechanical performance | High-strength, low-porosity components |

| Additive (SLS/EBS) | Unmatched design freedom for complex geometries | Prototypes & intricate parts |

| Liquid Phase (LPS) | Accelerated densification with a lower-melting-point additive | Specific material blends requiring fast processing |

Need help selecting the right sintering method for your lab's materials?

KINTEK specializes in providing the lab equipment and consumables needed for advanced material processing. Whether you're developing new alloys or producing high-performance ceramic components, our expertise can help you achieve optimal results. Let's discuss your project requirements and find the perfect solution for your laboratory needs.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What is vacuum sintering? Achieve Unmatched Purity and Performance for Advanced Materials

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- What is sintering reaction? Transform Powders into Dense Solids Without Melting

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?