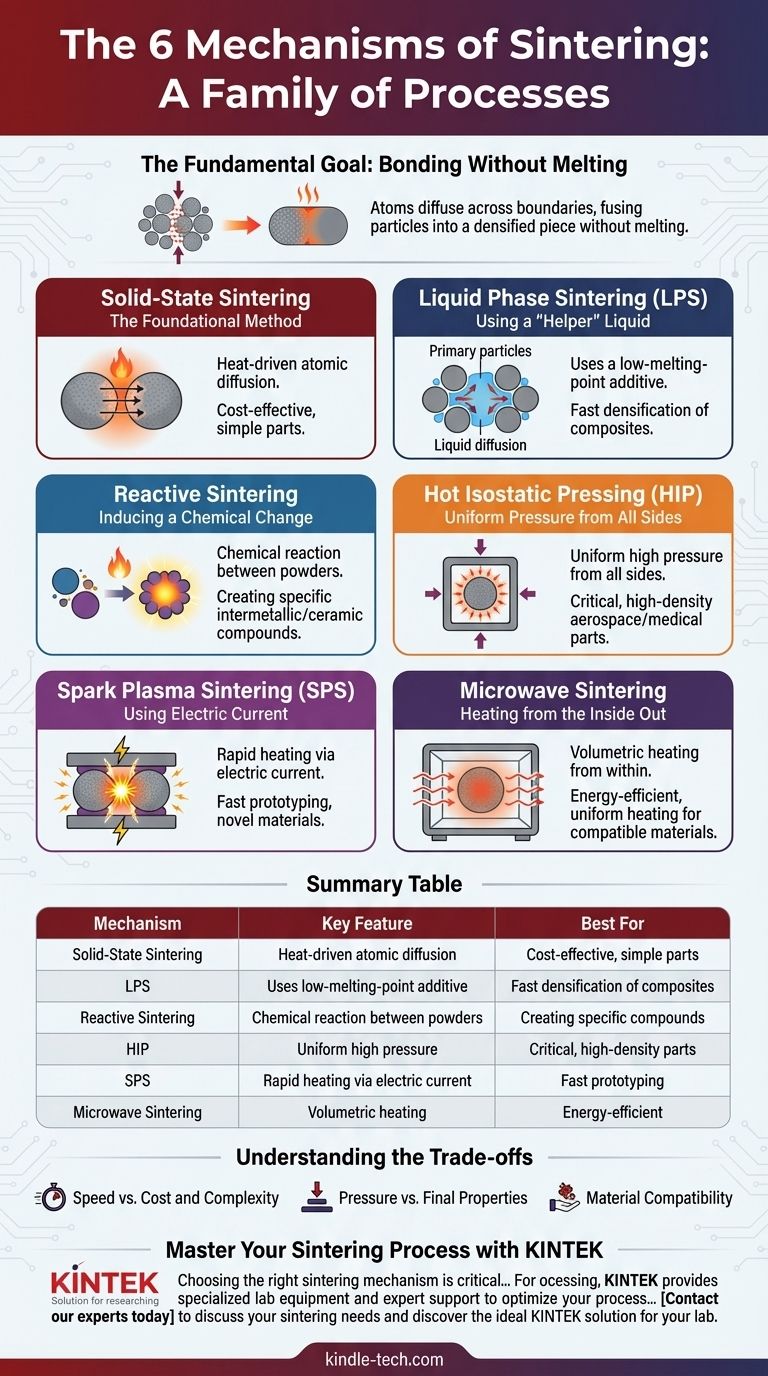

At its core, sintering is a family of processes, not a single technique. The six primary mechanisms are Solid-State Sintering, Liquid Phase Sintering, Reactive Sintering, Microwave Sintering, Spark Plasma Sintering, and Hot Isostatic Pressing. Each method uses a different combination of heat, pressure, and sometimes chemical reactions to bond powdered materials into a solid mass without melting them.

While all sintering aims to achieve the same goal—densifying a powder into a solid object—the mechanism you choose dictates the speed, final density, cost, and types of materials you can work with. Understanding these differences is the key to mastering the process.

The Fundamental Goal: Bonding Without Melting

Sintering is a cornerstone of materials science, particularly for processing metals and ceramics with extremely high melting points. Trying to melt and cast materials like tungsten would be incredibly energy-intensive and difficult to control.

Instead, sintering heats a compressed powder to a temperature just below its melting point. At this elevated temperature, the atoms at the contact points between particles become mobile and diffuse across the boundaries, effectively fusing the particles into a single, densified piece. This process reduces the internal porosity and strengthens the final object.

The Six Primary Sintering Mechanisms

While the underlying principle of atomic diffusion is common, the methods for encouraging it vary significantly. These different approaches are the six primary mechanisms of sintering.

Solid-State Sintering: The Foundational Method

This is the most classic form of sintering. A compacted powder is heated in a controlled atmosphere, allowing atoms to slowly migrate across the boundaries of touching particles.

This process is driven entirely by thermal energy reducing the material's surface energy. It is relatively simple but can be a slow process to achieve high density.

Liquid Phase Sintering (LPS): Using a "Helper" Liquid

In LPS, a small amount of an additive with a lower melting point is mixed with the primary powder. When heated, this additive melts and becomes a liquid phase that wets the solid particles.

This liquid acts as a rapid transport path, accelerating the rearrangement and diffusion of the primary material. It dramatically speeds up densification and is excellent for creating low-porosity components. The liquid is often driven off or incorporated into the final structure upon cooling.

Reactive Sintering: Inducing a Chemical Change

This mechanism involves using two or more different powders that chemically react with each other during heating. The reaction itself generates heat and forms a new, stable compound that bonds the structure together.

Reactive sintering is not just a physical bonding process but a chemical transformation. It is used to create specific intermetallic or ceramic compounds directly from their elemental powders.

Hot Isostatic Pressing (HIP): Uniform Pressure from All Sides

HIP combines high heat with high-pressure inert gas applied uniformly (isostatically) from all directions. This immense pressure physically forces the particles together, eliminating voids.

By applying external pressure, HIP can achieve nearly 100% density at temperatures lower than what would be required for solid-state sintering alone. It is a go-to method for critical, high-performance components in aerospace and medical applications.

Spark Plasma Sintering (SPS): Using Electric Current

SPS is a rapid consolidation technique that uses a combination of physical pressure and a pulsed DC electrical current. The current passes directly through the powder particles, creating extremely rapid and localized heating at their contact points.

This localized heating, sometimes creating a "spark plasma," dramatically accelerates diffusion and bonding. SPS can densify materials in a matter of minutes, compared to the hours required for conventional methods.

Microwave Sintering: Heating from the Inside Out

Unlike conventional furnaces that heat from the outside in, microwave sintering uses microwave radiation to heat the material volumetrically. The energy is absorbed throughout the body of the material, leading to more uniform and much faster heating.

This method can reduce processing time and save energy, but it is only effective for materials that couple well with microwave energy.

Understanding the Trade-offs

Choosing a sintering mechanism involves balancing competing factors. No single method is universally superior; the optimal choice is always context-dependent.

Speed vs. Cost and Complexity

Rapid methods like Spark Plasma Sintering (SPS) and Microwave Sintering can drastically cut down production time. However, the equipment is more complex and expensive than a conventional furnace used for Solid-State Sintering.

Pressure vs. Final Properties

Pressure-assisted methods like Hot Isostatic Pressing (HIP) produce parts with exceptional density and mechanical properties. This performance comes at the cost of sophisticated, high-pressure equipment. Non-pressure methods may be more economical but may not achieve the same level of densification.

Material Compatibility

The choice of material often dictates the mechanism. Reactive Sintering is inherently limited to systems with specific chemical reactions. Microwave Sintering requires a material that absorbs microwave energy efficiently. Liquid Phase Sintering depends on finding a suitable additive that melts at the right temperature.

Making the Right Choice for Your Application

Your final decision should be guided by the primary objective of your project.

- If your primary focus is cost-effective production of simple metal or ceramic parts: Solid-State Sintering is the established, reliable, and economical workhorse.

- If your primary focus is achieving maximum density and performance for critical components: Hot Isostatic Pressing (HIP) is the industry standard for eliminating all porosity.

- If your primary focus is rapid prototyping or processing novel materials: Spark Plasma Sintering (SPS) offers unmatched speed and control over the microstructure.

- If your primary focus is creating a dense composite material efficiently: Liquid Phase Sintering (LPS) is an excellent choice for accelerating densification with the right additives.

Ultimately, selecting the right sintering mechanism is about matching the tool to the specific material and the desired properties of the final component.

Summary Table:

| Mechanism | Key Feature | Best For |

|---|---|---|

| Solid-State Sintering | Heat-driven atomic diffusion | Cost-effective, simple parts |

| Liquid Phase Sintering (LPS) | Uses a low-melting-point additive | Fast densification of composites |

| Reactive Sintering | Chemical reaction between powders | Creating specific intermetallic/ceramic compounds |

| Hot Isostatic Pressing (HIP) | Uniform high pressure from all sides | Critical, high-density aerospace/medical parts |

| Spark Plasma Sintering (SPS) | Rapid heating via electric current | Fast prototyping, novel materials |

| Microwave Sintering | Volumetric heating from within | Energy-efficient, uniform heating for compatible materials |

Master Your Sintering Process with KINTEK

Choosing the right sintering mechanism is critical to achieving the desired density, strength, and efficiency for your lab's materials. Whether you need the cost-effectiveness of solid-state sintering or the rapid results of Spark Plasma Sintering, KINTEK provides the specialized lab equipment and expert support to optimize your process.

We serve laboratories working with advanced ceramics, metals, and composites, offering furnaces and systems tailored for each sintering method. Let us help you select the right tool to enhance your research and production outcomes.

Contact our experts today to discuss your sintering needs and discover the ideal KINTEK solution for your lab.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- How does precise temperature control affect FeCoCrNiMnTiC high-entropy alloys? Master Microstructural Evolution

- Why is a high vacuum environment necessary in sintering equipment for TiAl alloys? Ensure High-Purity Metal Bonding