Injection molding machines offer unmatched efficiency for mass-producing parts, making them a cornerstone of modern manufacturing. The process is defined by its ability to create vast quantities of identical items at a very low cost per unit, leveraging automation and rapid cycle times. However, this remarkable efficiency is predicated on a significant upfront investment in custom tooling.

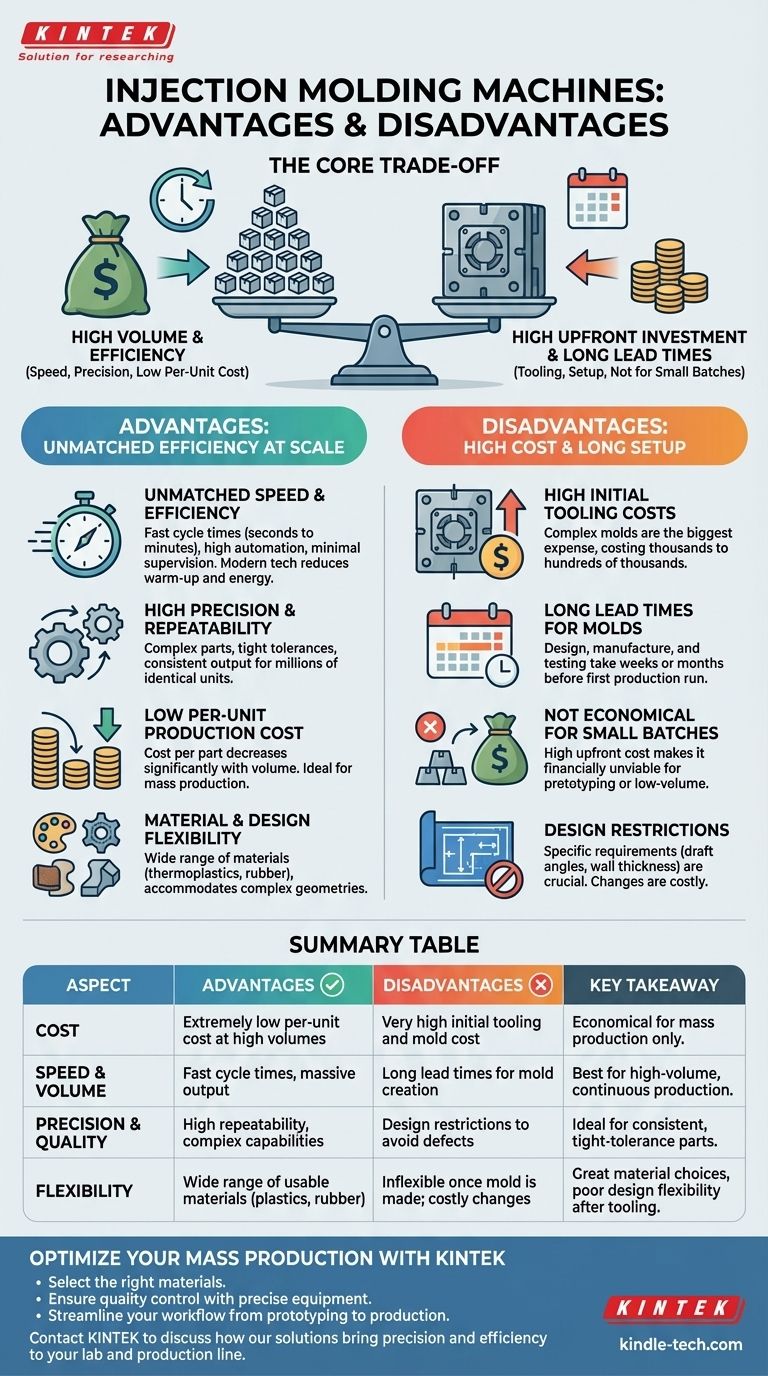

The core trade-off of injection molding is simple: it exchanges high initial tooling costs and long lead times for exceptional speed, high precision, and an extremely low per-part cost, but only at high production volumes.

The Core Advantages of Injection Molding

The primary benefits of injection molding revolve around its suitability for large-scale, repeatable manufacturing. When a project's volume justifies the initial investment, its advantages are difficult to match.

Unmatched Speed and Efficiency

An injection molding machine can produce parts with cycle times ranging from a few seconds to a minute. Once the machine is running, the process is highly automated, requiring minimal supervision. This leads to a massive output in a short amount of time.

Modern technologies like induction heating further reduce warm-up times and energy consumption, making the process even more efficient.

High Precision and Repeatability

Injection molding is an exceptionally precise process. It allows for the creation of complex and intricate parts with tight tolerances, and it can produce millions of these parts with virtually no variation between them. This consistency is critical for products that require high-quality, interchangeable components.

Low Per-Unit Production Cost

While the initial mold is expensive, the cost per part becomes extremely low as production volume increases. The combination of fast cycle times, automation, and low scrap rates spreads the initial tooling cost thinly across a large number of units, making it highly economical for mass production.

Material and Design Flexibility

A vast range of materials can be used, including thermoplastics, thermosets like rubber, elastomers, and even some metals. This allows engineers to select the perfect material for a part's specific mechanical and aesthetic requirements. The process also accommodates complex geometries that would be difficult or impossible to produce with other methods.

Understanding the Trade-offs and Disadvantages

The power of injection molding is not without its limitations. These disadvantages are primarily linked to the cost and time associated with creating the initial mold.

High Initial Tooling Costs

The mold, or tool, is the single greatest expense. These are complex, high-precision tools machined from hardened steel, and their cost can range from thousands to hundreds of thousands of dollars depending on the part's complexity, size, and required material.

Long Lead Times for Molds

Designing, manufacturing, and testing a production-ready mold is a time-consuming process. It can easily take weeks or even months to go from a final part design to the first production run. This makes injection molding unsuitable for projects with tight deadlines for the initial batch.

Not Economical for Small Batches

The high upfront cost of the mold makes injection molding financially unviable for prototyping or low-volume production. The cost per part is only advantageous when producing thousands or tens of thousands of units or more.

Design Restrictions

Parts must be designed specifically for the injection molding process. This includes considerations like draft angles (to allow the part to be ejected), uniform wall thickness (to prevent defects), and avoiding undercuts that would trap the part in the mold. Failing to follow these design principles can lead to costly mold redesigns and production delays.

How to Make the Right Choice

Deciding whether to use an injection molding machine depends entirely on your project's scale, budget, and timeline.

- If your primary focus is mass production and low cost-per-part: Injection molding is the definitive choice for its unmatched speed and economy at scale.

- If your primary focus is rapid prototyping or low-volume runs: The high tooling cost and long lead time make methods like 3D printing or CNC machining far more suitable.

- If your primary focus is creating identical, high-precision parts: Injection molding excels at repeatability, making it ideal for products requiring tight tolerances across thousands of units.

Ultimately, choosing injection molding is a strategic decision to trade significant upfront investment for unparalleled efficiency and precision at scale.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Cost | Extremely low per-unit cost at high volumes | Very high initial tooling and mold cost |

| Speed & Volume | Fast cycle times, ideal for mass production | Long lead times for mold creation; not for low volumes |

| Precision & Quality | High repeatability and complex part capability | Design restrictions (draft angles, wall thickness) |

| Flexibility | Wide range of usable materials (plastics, rubber) | Inflexible once mold is made; changes are costly |

Ready to optimize your mass production process?

Choosing the right manufacturing method is critical to your project's success and budget. At KINTEK, we specialize in providing the lab equipment and consumables needed to support your R&D and quality control for injection molding and other processes.

Let our experts help you:

- Select the right materials for your application.

- Ensure quality control with precise testing equipment.

- Streamline your workflow from prototyping to production.

Don't let manufacturing challenges slow you down. Contact KINTEK today to discuss how our solutions can bring precision and efficiency to your laboratory and production line.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the difference between injection molding and pressure molding? A Guide to Choosing the Right Process

- What is the injection molding process? A Guide to High-Volume Part Production

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing

- What is the application of injection moulding machine? Powering Mass Production for Complex Parts