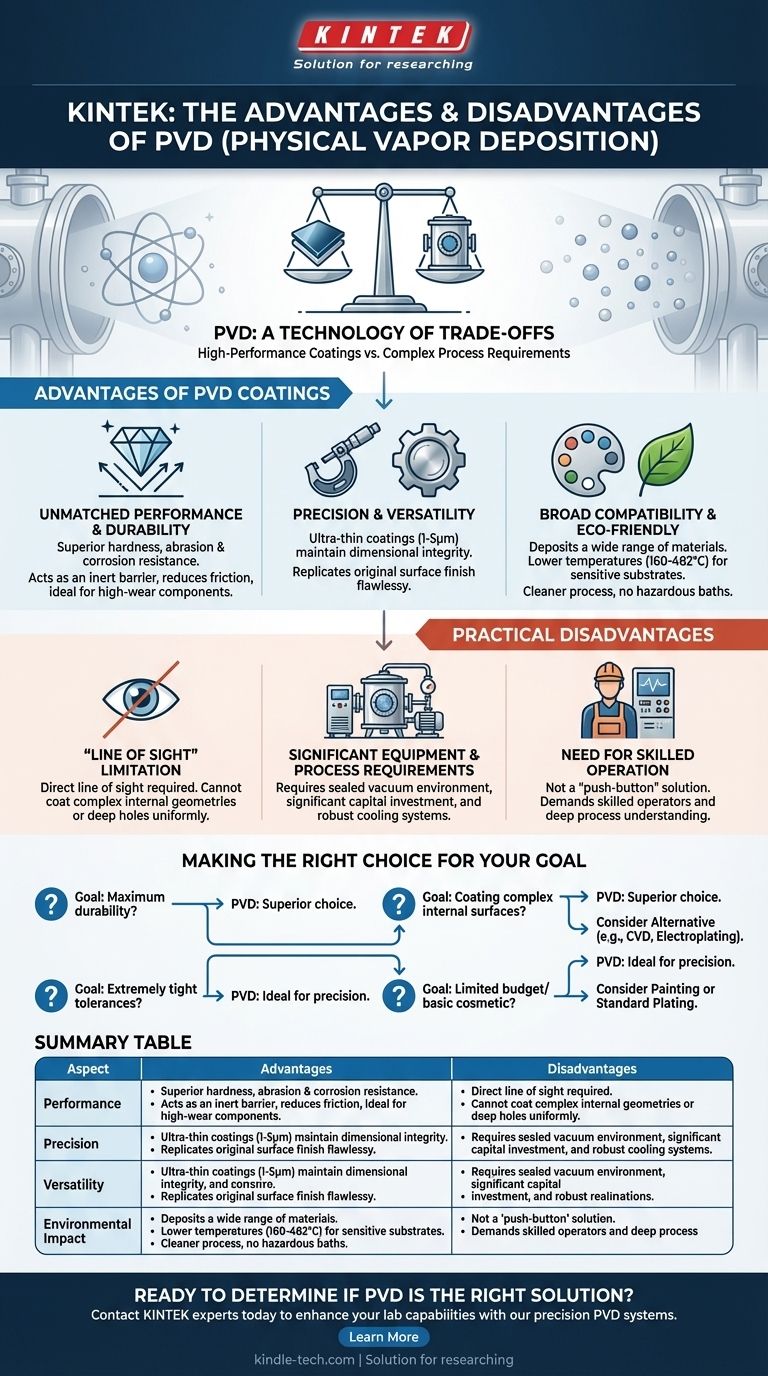

At its core, Physical Vapor Deposition (PVD) is a technology of trade-offs, offering exceptionally high-performance, thin-film coatings in exchange for a process that demands significant investment and control. It produces coatings that are harder, more corrosion-resistant, and more precise than many traditional methods, but its operational requirements, including a vacuum environment and line-of-sight application, make it a specialized solution rather than a universal one.

The decision to use PVD hinges on a simple question: Does the required performance of the final product justify the cost and complexity of a high-precision, vacuum-based coating process? For applications demanding extreme durability and dimensional accuracy, the answer is often a definitive yes.

The Core Advantages of PVD Coatings

PVD's primary benefits stem from its ability to create thin, highly adherent films with superior physical properties. This makes it an invaluable tool in advanced manufacturing.

Unmatched Performance and Durability

PVD coatings create a powerful physical bond to the substrate, resulting in finishes that are far more durable than methods like electroplating. They provide exceptional abrasion resistance and hardness, which is why they are a standard for high-performance cutting tools.

These coatings also serve as an inert barrier against the environment, offering superior corrosion resistance and thermal stability. The resulting surface is often lubricious, significantly reducing friction on moving components.

Precision and Versatility

The PVD process allows for extremely thin coatings, typically in the range of 1 to 5 micrometers (.00004 to .0002 inches). This ensures that the dimensional integrity of the original part is maintained, making it ideal for components with tight tolerances.

Furthermore, PVD flawlessly replicates the original surface finish. A polished substrate will result in a polished coating, and a textured substrate will yield a textured coating, with no excessive build-up on edges or corners.

Broad Material and Substrate Compatibility

One of PVD's greatest strengths is its versatility. It can be used to deposit nearly any inorganic material and even some organic ones, creating a vast palette of potential coating properties.

Crucially, PVD operates at lower temperatures (typically 160-482°C / 320-900°F) than alternative methods like Chemical Vapor Deposition (CVD). This allows it to coat temperature-sensitive substrates that would be damaged or have their core properties altered by higher-heat processes.

Environmental and Safety Benefits

Compared to conventional methods like electroplating, PVD is a significantly cleaner, more environmentally friendly process. It does not use the hazardous chemical baths common in plating, which simplifies waste disposal and reduces operator risk.

Understanding the Practical Disadvantages

The high-performance nature of PVD comes with distinct operational costs and limitations. These factors are critical to consider when evaluating it against other technologies.

The "Line of Sight" Limitation

PVD is a "line of sight" process. The coating material travels in a straight line from the source to the substrate. If a surface cannot be seen directly from the source, it will not be coated.

This is a major constraint for parts with complex internal geometries or deep, narrow holes. Such components often require rotation on complex fixtures to achieve full coverage, and some designs are simply impossible to coat uniformly.

Significant Equipment and Process Requirements

PVD is not a simple process. It must take place within a sealed vacuum chamber, which represents a significant capital investment and adds complexity to production.

The process also generates a substantial amount of heat, necessitating a robust cooling water system to prevent the chamber and internal components from overheating.

Need for Skilled Operation

Because of the vacuum, temperature, and high-voltage plasma environment, PVD equipment requires skilled and well-trained operators. It is not a "push-button" solution and demands a deep understanding of the process parameters to achieve consistent, high-quality results.

Making the Right Choice for Your Goal

Ultimately, PVD is a strategic choice. Its advantages are profound, but its limitations are real. Use your primary objective to guide your decision.

- If your primary focus is maximum durability and wear resistance: PVD is a superior choice over most other methods for high-wear components like cutting tools, dies, and aerospace parts.

- If you are coating parts with complex, non-visible internal surfaces: You must account for PVD's line-of-sight limitation and may need to consider alternative methods like CVD or electroplating.

- If your priority is maintaining extremely tight dimensional tolerances: PVD is ideal due to its thin, uniform application that preserves the precise geometry of the underlying part.

- If your project has a limited budget or only requires basic cosmetic or corrosion protection: The capital and operational costs of PVD may be excessive, making painting or standard plating a more practical choice.

Understanding these fundamental trade-offs empowers you to select PVD not just for its capabilities, but for its strategic fit with your specific engineering goal.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Performance | Superior hardness, wear, and corrosion resistance | Requires high capital investment |

| Precision | Maintains dimensional accuracy; replicates surface finish | Line-of-sight process limits complex geometries |

| Versatility | Works with various materials and temperature-sensitive substrates | Demands skilled operation and training |

| Environmental Impact | Cleaner process; no hazardous chemical baths | Significant energy and cooling water requirements |

Ready to determine if PVD is the right coating solution for your lab or manufacturing needs? At KINTEK, we specialize in providing advanced lab equipment and consumables, including PVD systems tailored for precision and durability. Our experts can help you navigate the trade-offs to achieve optimal performance for your specific application. Contact us today to discuss your project requirements and discover how KINTEK’s solutions can enhance your laboratory’s capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition