At its core, a colloid mill's primary advantage is its ability to apply intense mechanical shear to a fluid, making it exceptionally effective at particle size reduction, dispersion, and emulsification. This capability allows it to produce stable, homogenous mixtures with a uniform consistency, which is why it is a foundational piece of equipment in the food, pharmaceutical, chemical, and cosmetic industries.

A colloid mill is not a universal grinder, but a specialized high-shear mixer. Its true advantage is providing a robust and cost-effective method for creating stable emulsions and dispersions where a fine, but not necessarily nano-scale, particle size is the goal.

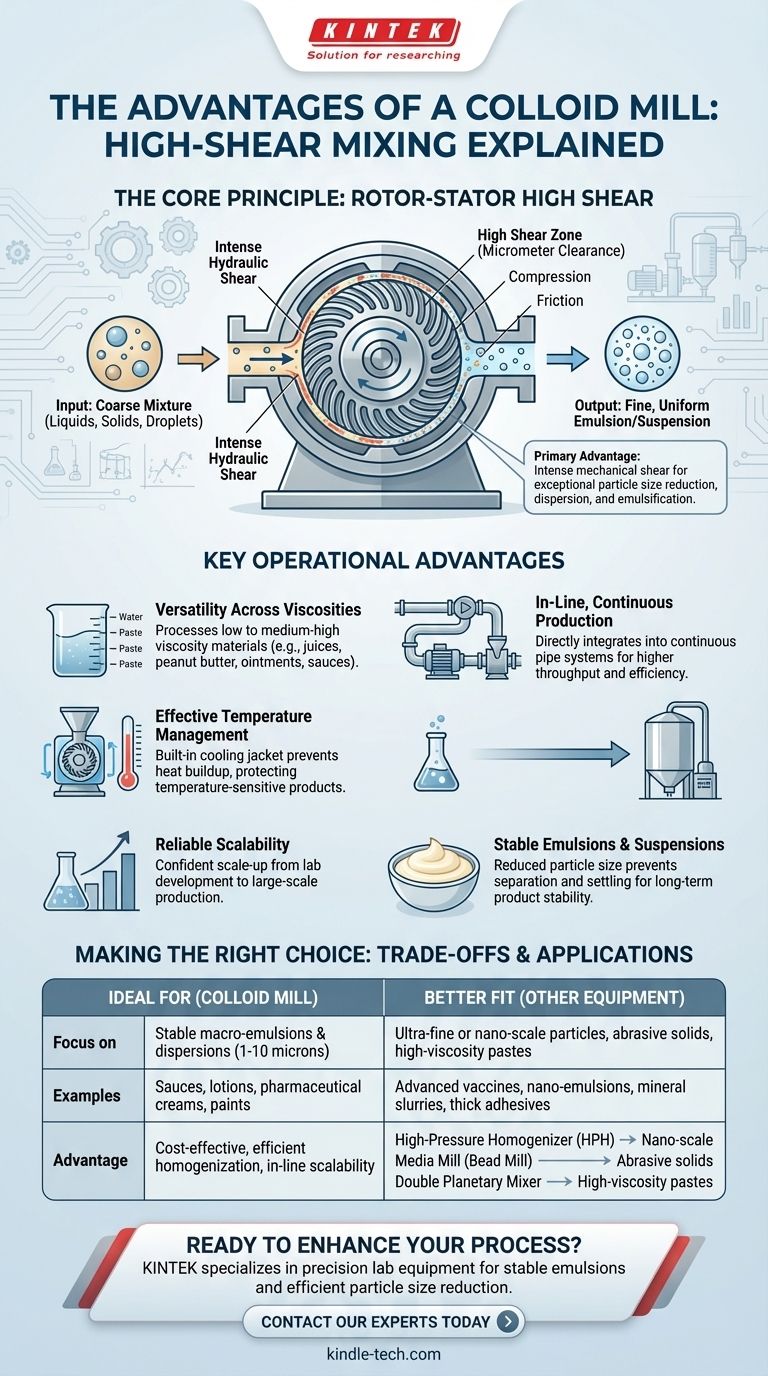

The Core Principle: How High Shear Drives Results

A colloid mill operates on a simple yet powerful principle: the rotor-stator system. Understanding this mechanism is key to grasping its advantages.

The Rotor-Stator Mechanism

A colloid mill consists of a high-speed rotor that spins with very little clearance (often measured in micrometers) relative to a stationary part, the stator. Both the rotor and stator are typically cone-shaped and feature intricate patterns of grooves and teeth.

As the product is fed into the mill, it is subjected to intense hydraulic shear, compression, and friction as it is forced through the narrow gap between the spinning rotor and the fixed stator.

Intense Particle Size Reduction

The primary function of this high shear is to break down particles. For an emulsion (like mayonnaise or salad dressing), it tears apart larger droplets of oil and disperses them uniformly within a water base. For a suspension (like a paint or pharmaceutical cream), it breaks down clumps of solid particles (agglomerates).

This action results in a significantly smaller and more uniform particle size distribution, which is critical for the quality and stability of the final product.

Creating Stable Emulsions and Suspensions

By reducing particle and droplet size, a colloid mill dramatically increases the surface area of the dispersed phase. This makes the resulting mixture far more resistant to separation over time.

A well-milled emulsion will not break, and a suspension will not settle out quickly. This long-term stability is a direct advantage of the effective homogenization process.

Key Operational Advantages

Beyond the core function of high-shear mixing, colloid mills offer several practical benefits that make them a preferred choice for many industrial processes.

Versatility Across Viscosities

Colloid mills can effectively process a wide range of materials, from low-viscosity liquids like juices and inks to medium-to-high viscosity products like peanut butter, ointments, and thick sauces. This flexibility allows a single machine to be used for multiple product lines.

Suitability for In-Line, Continuous Production

Many colloid mills are designed for in-line operation, meaning they can be integrated directly into a continuous production pipe system. This is far more efficient for large-scale manufacturing than batch processing, which requires stopping to load and unload a tank. In-line processing ensures higher throughput and greater product consistency.

Effective Temperature Management

The intense shear action naturally generates heat. To manage this, most industrial colloid mills are built with a cooling jacket. This allows a cooling fluid (like water or glycol) to circulate around the mill, removing excess heat and protecting temperature-sensitive products like dairy or certain active pharmaceutical ingredients.

Scalability from Lab to Factory

The rotor-stator principle scales reliably. A formulation developed on a small, laboratory-scale colloid mill can be confidently scaled up to a large, production-capacity mill. This predictability is crucial for product development and manufacturing efficiency.

Understanding the Trade-offs

To use a colloid mill effectively, you must also understand its limitations. It is a powerful tool, but not the right one for every job.

Limitation 1: Particle Size vs. High-Pressure Homogenizers

While a colloid mill is excellent for creating fine dispersions (typically in the 1-10 micron range), it cannot achieve the ultra-fine or nano-scale particle sizes produced by a high-pressure homogenizer (HPH). For applications requiring the absolute smallest particle size, such as advanced vaccines or nano-emulsions, an HPH is the superior choice.

Limitation 2: Sensitivity to Abrasive Materials

The precise, tight tolerance between the rotor and stator makes the mill vulnerable to wear from hard, abrasive particles. Processing materials with abrasive solids (like mineral slurries) will cause rapid wear on these critical components, leading to increased maintenance costs and reduced performance. In these cases, equipment like a media mill (bead mill) is more appropriate.

Limitation 3: High Viscosity Limits

Although versatile, a colloid mill will struggle with extremely viscous, paste-like materials that do not flow easily. For products like thick adhesives or dense caulks, a double planetary mixer or high-viscosity disperser is a better fit.

Making the Right Choice for Your Application

Selecting the right equipment depends entirely on your product and processing goals.

- If your primary focus is creating stable macro-emulsions like mayonnaise, sauces, or lotions: The colloid mill is an ideal, cost-effective choice for achieving the desired texture and stability.

- If your primary focus is processing abrasive solids or hard-to-grind materials: You should consider media mills or other equipment designed specifically to handle high wear.

- If your primary focus is achieving the smallest possible particle size for applications like vaccines or nano-suspensions: A high-pressure homogenizer is the necessary tool for the job.

- If your primary focus is scaling a process from R&D to large-scale continuous manufacturing: The inherent scalability and in-line capability of a colloid mill make it a strong contender.

By understanding its specific strengths and limitations, you can leverage the colloid mill as a powerful and efficient tool for your processing goals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Intense Mechanical Shear | Effective particle size reduction and dispersion for stable, homogenous mixtures. |

| Versatility Across Viscosities | Processes a wide range of materials, from low-viscosity liquids to thick pastes. |

| In-Line, Continuous Production | Enables high-throughput, consistent manufacturing integrated into pipe systems. |

| Effective Temperature Management | Built-in cooling jacket protects temperature-sensitive products during processing. |

| Reliable Scalability | Easily scale formulations from lab R&D to full-scale production with predictable results. |

Ready to enhance your production process with a high-shear colloid mill?

KINTEK specializes in precision lab equipment, including colloid mills for industries like food, pharmaceuticals, and cosmetics. Whether you're developing a new formulation in the lab or scaling up for continuous manufacturing, our expertise ensures you get the right equipment for stable emulsions and efficient particle size reduction.

Contact our experts today to discuss how a KINTEK colloid mill can improve your product quality and processing efficiency!

Visual Guide

Related Products

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Laboratory Micro Tissue Grinding Mill Grinder

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

People Also Ask

- What is an example of pulverized? From Crushing Rocks to Winning Debates

- What are the different types of laboratory mills? Choose the Right Grinder for Your Sample Material

- What is the primary function of mechanical grinding equipment in PHBV production? Optimize Feedstock for Maximum Yield

- Why is it necessary to grind LAGP samples before XRD? Eliminate Preferred Orientation for Accurate Phase Analysis

- What are the advantages of using a laboratory ultrasonic homogenizer for PHA extraction? Faster Physical Cell Disruption

- Why is an alumina mortar used for grinding dried Yttrium Oxide precursor materials? Ensure Maximum Purity and Quality

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries

- What role does a vibration mill play in Zeta potential measurements? Prepare Ultrafine Samples for Accurate Analysis