In essence, a colloidal mill excels at producing extremely stable emulsions and suspensions through intense mechanical shear. Its primary advantages are its ability to achieve significant particle size reduction for soft materials, its high throughput for continuous industrial processes, and its robust, relatively simple design.

The core value of a colloidal mill lies not just in making particles smaller, but in imparting the high-energy shear necessary to create uniform, stable, and finely dispersed mixtures that are critical for product quality in the food, pharmaceutical, and chemical industries.

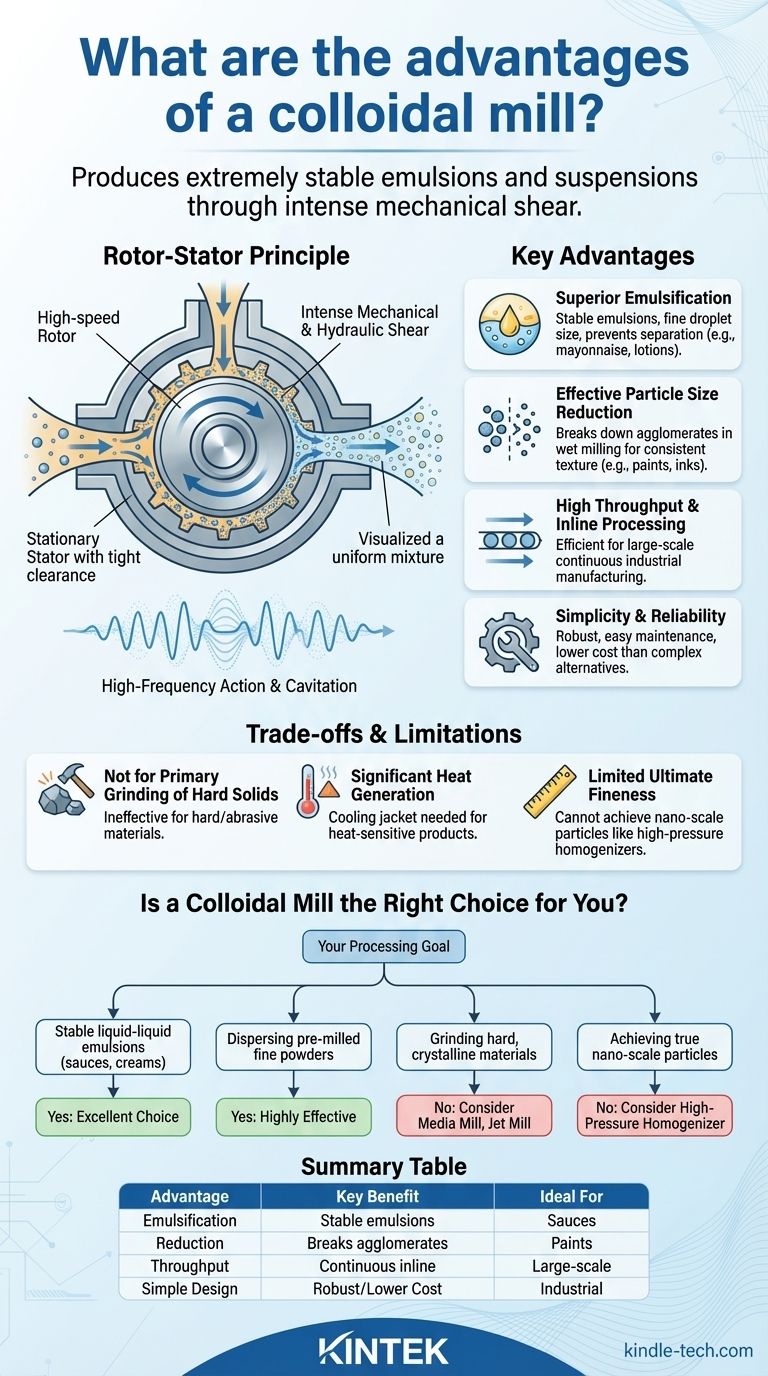

How a Colloidal Mill Achieves Its Results

A colloidal mill's effectiveness stems from a simple but powerful mechanical principle. Understanding this mechanism is key to appreciating its advantages.

The Rotor-Stator Principle

The heart of the mill is a high-speed rotor that spins with very tight clearance (often measured in micrometers) inside a stationary housing called the stator. Both the rotor and stator are typically cone-shaped and may be toothed or grooved.

Intense Mechanical and Hydraulic Shear

As material is fed into the gap between the rotor and stator, it is subjected to immense shearing forces. The high rotational speed creates a massive velocity difference across a tiny space, literally tearing apart droplets and soft particle agglomerates.

High-Frequency Action

The material is also subjected to intense vibration, impact, and cavitation as it is centrifugally forced through the intricate grooves or teeth of the rotor and stator. This combination of forces ensures a thorough and uniform processing effect.

Key Advantages Explained

The unique operating principle of a colloidal mill translates directly into several key processing advantages.

Superior Emulsification and Homogenization

The intense shear is exceptionally effective at breaking down and dispersing immiscible liquid droplets, such as oil in water. This creates a highly stable emulsion with a fine droplet size, preventing separation and improving product texture and shelf life, as seen in products like mayonnaise, sauces, and lotions.

Effective Particle Size Reduction

For wet milling applications, a colloidal mill excels at breaking down agglomerates of solid particles and dispersing them uniformly throughout a liquid base. This is critical for producing paints, inks, pharmaceutical suspensions, and other products where a smooth, consistent texture is required.

High Throughput and Inline Processing

Colloidal mills are easily integrated into continuous production lines. Their ability to process material at a high flow rate makes them far more efficient for large-scale manufacturing than batch-style mixers.

Simplicity and Reliability

Compared to more complex technologies like high-pressure homogenizers, colloidal mills have a relatively simple and robust mechanical design. This results in greater operational reliability, easier maintenance, and a lower initial capital cost.

Understanding the Trade-offs and Limitations

To use a colloidal mill effectively, it is critical to understand what it is not designed to do. No single technology is a universal solution.

Not for Primary Grinding of Hard Solids

A colloidal mill is not a primary grinder. It is ineffective for breaking down hard, abrasive, or crystalline materials from a large starting size. That task is better suited for technologies like hammer mills or ball mills.

Significant Heat Generation

The intense energy input from the high-shear action generates considerable heat. For temperature-sensitive materials, such as certain pharmaceuticals or food products, a cooling jacket around the mill housing is often a necessity to prevent product degradation.

Limited Ultimate Fineness

While excellent for creating fine dispersions in the micron range, a colloidal mill generally cannot achieve the sub-micron or nano-scale particle sizes possible with high-pressure homogenizers or media (bead) mills. Its effectiveness diminishes as particle size becomes extremely small.

Is a Colloidal Mill the Right Choice for You?

Selecting the correct milling technology depends entirely on your material and your final product goals.

- If your primary focus is creating stable liquid-liquid emulsions (e.g., sauces, creams, lotions): A colloidal mill is an excellent, industry-standard choice for achieving the required stability and texture.

- If your primary focus is dispersing pre-milled fine powders into a liquid (e.g., pigments, APIs): It is highly effective for breaking up agglomerates and ensuring a uniform, homogenous suspension.

- If your primary focus is grinding hard, crystalline materials from a coarse state: You should investigate other technologies like a media mill, jet mill, or ball mill.

- If your primary focus is achieving true nano-scale particle sizes for advanced applications: A high-pressure homogenizer is the more appropriate and powerful tool for the job.

Understanding these core capabilities ensures you select a technology that aligns perfectly with your processing goals and product quality requirements.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Superior Emulsification | Creates stable, fine emulsions | Sauces, lotions, creams |

| Particle Size Reduction | Breaks down soft agglomerates | Paints, inks, suspensions |

| High Throughput | Enables continuous inline processing | Large-scale manufacturing |

| Simple & Reliable Design | Robust, easy to maintain, lower cost | Industrial applications |

Ready to enhance your production line with a colloidal mill? KINTEK specializes in high-performance lab equipment and consumables, providing reliable colloidal mills that deliver stable emulsions, uniform dispersions, and efficient continuous processing for industries like food, pharmaceuticals, and chemicals. Let our experts help you achieve superior product quality and throughput. Contact us today to find the perfect solution for your laboratory needs!

Visual Guide

Related Products

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Hybrid Tissue Grinding Mill

- Three-dimensional electromagnetic sieving instrument

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

People Also Ask

- How does jet milling equipment operate when producing ultrafine biomass powders? Achieve High-Purity Micronized Results

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries

- What is an example of pulverized? From Crushing Rocks to Winning Debates

- How does the argon atmosphere protection in a ball mill affect the final quality of CuCr50 alloy powder? Explained

- What is the particle size for XRF? Achieve Accurate and Reliable Elemental Analysis

- Which is the mill preferred for wet grinding? Choose the Right Mill for Your Particle Size Goal

- Why are high-precision ball mills necessary for alkaline earth metal oxide catalysts? Optimize Reactivity and Precision

- What are the disadvantages of producing a laboratory sample from a gross sample by crushing and grinding? Avoid Contamination and Data Errors