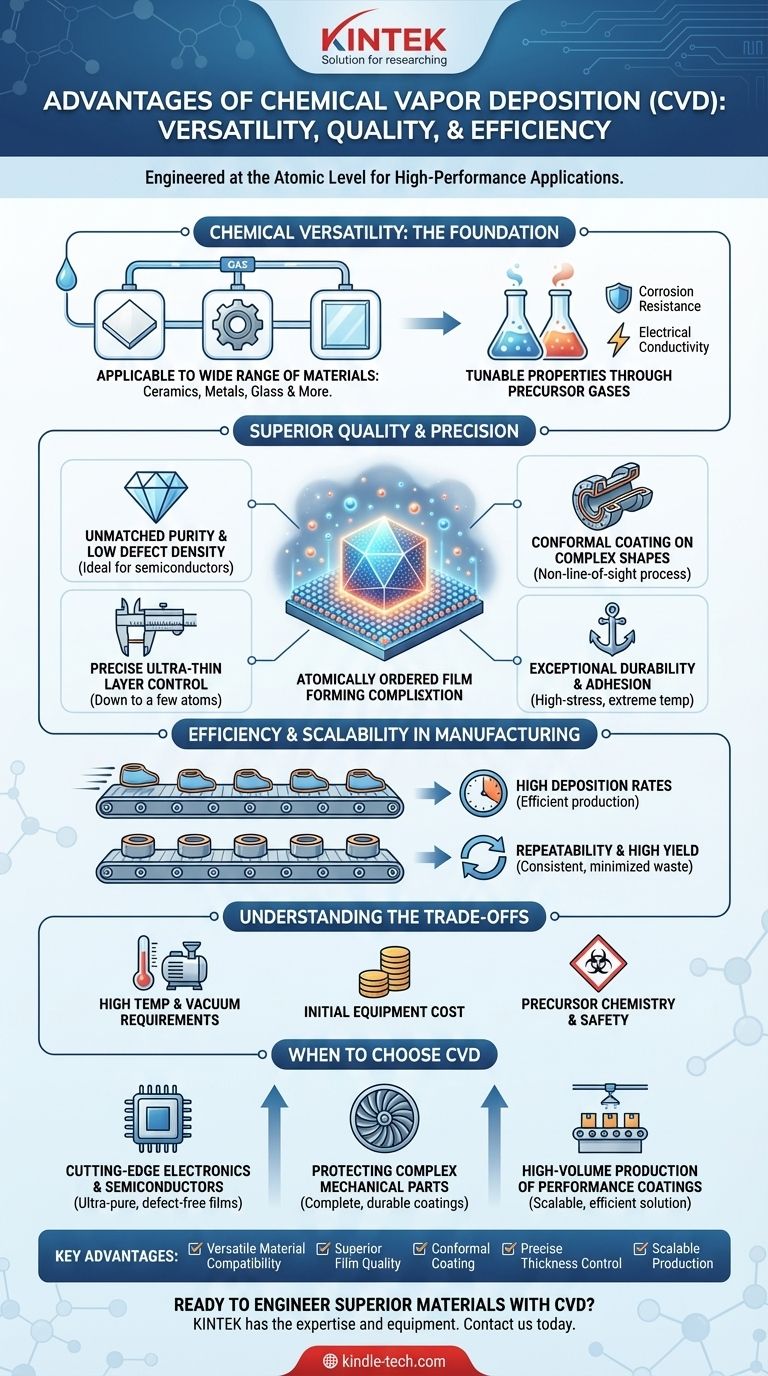

In short, Chemical Vapor Deposition (CVD) offers a powerful combination of versatility, quality, and efficiency. This process is renowned for its ability to produce exceptionally pure, uniform, and durable thin films on a wide variety of materials. Its unique non-line-of-sight nature allows it to coat complex shapes evenly, a feat that many other deposition techniques cannot achieve.

The true advantage of CVD is not just its ability to apply a coating, but its power to precisely engineer material properties at the atomic level. It transforms a surface by building a new, high-performance layer from gaseous chemical precursors, enabling functionality that is otherwise impossible.

The Foundation of CVD's Power: Chemical Versatility

Chemical Vapor Deposition is defined by its use of chemical reactions, which is the source of its immense flexibility. Unlike physical methods that essentially transfer a solid material from a source to a target, CVD builds the film atom by atom from gas.

Applicable to a Wide Range of Materials

CVD is not limited to a specific class of substrate. It can be effectively used to deposit films on ceramics, metals, glass, and many other materials, making it a go-to process for diverse engineering challenges.

Tunable Properties Through Precursor Gases

The final properties of the coating are determined by the precursor gases used in the reaction. By selecting and optimizing these gases, engineers can create films designed for specific purposes, such as extreme corrosion resistance, abrasion resistance, or electrical conductivity.

Achieving Superior Film Quality and Precision

The quality of the deposited film is where CVD truly excels. The process allows for a level of control that is critical for high-performance applications.

Unmatched Purity and Low Defect Density

Because the film is constructed from highly purified gases, the resulting layer is also exceptionally pure. This is crucial for applications like semiconductors and high-performance electronics, where impurities can degrade performance. For materials like graphene, CVD is a leading method for producing large, uniform sheets with a low defect count.

Uniform, Conformal Coatings on Complex Shapes

CVD is a non-line-of-sight process. Think of it like a gas filling every corner of a room, rather than spray paint which can only hit surfaces it can see. This allows CVD to apply a perfectly uniform and conformal coating over intricate and complex geometries, ensuring complete protection and consistent properties.

Precise Control Over Ultra-Thin Layers

The process allows for meticulous control over film thickness, enabling the creation of ultra-thin layers just a few atoms thick. This precision is essential for manufacturing modern electrical circuits, optical coatings, and other micro-scale devices.

Exceptional Durability and Adhesion

The chemical bond formed between the substrate and the deposited film results in commendable adhesion. These coatings are highly durable and can withstand high-stress environments, extreme temperatures, and significant temperature variations without failing.

Understanding the Trade-offs

While powerful, CVD is not a universal solution. Understanding its operational requirements is key to making an informed decision.

High-Temperature and Vacuum Requirements

Many CVD processes require high temperatures to drive the necessary chemical reactions, which can limit the types of substrate materials that can be used. The process is also typically performed in a vacuum chamber, adding to the equipment's complexity and cost.

Precursor Chemistry and Safety

The precursor gases used in CVD can be toxic, flammable, or corrosive, requiring sophisticated handling procedures and safety protocols. The chemistry itself can be complex to develop and optimize for new materials or applications.

Initial Equipment Cost

Compared to simpler coating methods, the initial capital investment for a CVD system can be significant. The need for vacuum systems, gas handling, and temperature control makes it a more advanced manufacturing process.

Efficiency and Scalability in Manufacturing

For the right application, CVD is a highly effective and scalable manufacturing technique.

High Deposition Rates

Once optimized, CVD can achieve relatively high deposition rates compared to some other precision deposition techniques. This makes it efficient for coating parts in a production environment.

Repeatability and High Yield

The precise control over process parameters—such as temperature, pressure, and gas flow—leads to a highly repeatable outcome. This ensures consistency from batch to batch and results in a high manufacturing yield, minimizing wasted material and time.

When to Choose Chemical Vapor Deposition

Your choice of deposition technology should be guided by your end goal.

- If your primary focus is cutting-edge electronics or semiconductors: CVD is the superior choice for creating the ultra-pure, defect-free, and precisely thin films required for high-performance devices.

- If your primary focus is protecting complex mechanical parts: CVD's non-line-of-sight capability provides complete and durable coatings for wear, corrosion, and thermal protection on intricate geometries.

- If your primary focus is high-volume production of performance coatings: A well-established CVD process offers a scalable, efficient, and repeatable solution for manufacturing.

Ultimately, you should choose CVD when the performance, purity, and conformity of the film are more critical than the initial cost and complexity of the setup.

Summary Table:

| Key Advantage | Description |

|---|---|

| Versatile Material Compatibility | Deposits films on ceramics, metals, glass, and more. |

| Superior Film Quality | Creates exceptionally pure, uniform, and durable coatings. |

| Conformal Coating | Non-line-of-sight process evenly coats complex 3D shapes. |

| Precise Thickness Control | Enables the creation of ultra-thin layers, down to a few atoms. |

| Scalable Production | Offers high deposition rates and excellent batch-to-batch repeatability. |

Ready to Engineer Superior Materials with CVD?

If your laboratory demands high-purity, durable thin films for applications in semiconductors, advanced electronics, or protective coatings for complex parts, KINTEK has the expertise and equipment you need. Our CVD solutions are designed to deliver the precision and performance critical to your research and production.

Contact us today using the form below to discuss how our lab equipment can enhance your capabilities and drive your projects forward.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition