At its core, cold isostatic pressing (CIP) offers a unique method for compacting powders into a solid form with remarkably uniform density and strength. By using liquid to apply equal pressure from all directions, it overcomes the primary limitations of traditional pressing, making it ideal for creating large, complex parts or components from materials that are otherwise difficult to process.

The fundamental advantage of CIP is its use of uniform, all-sided hydrostatic pressure. This eliminates the die-wall friction inherent in conventional uniaxial pressing, resulting in components with superior density uniformity, predictable final properties, and greater design freedom.

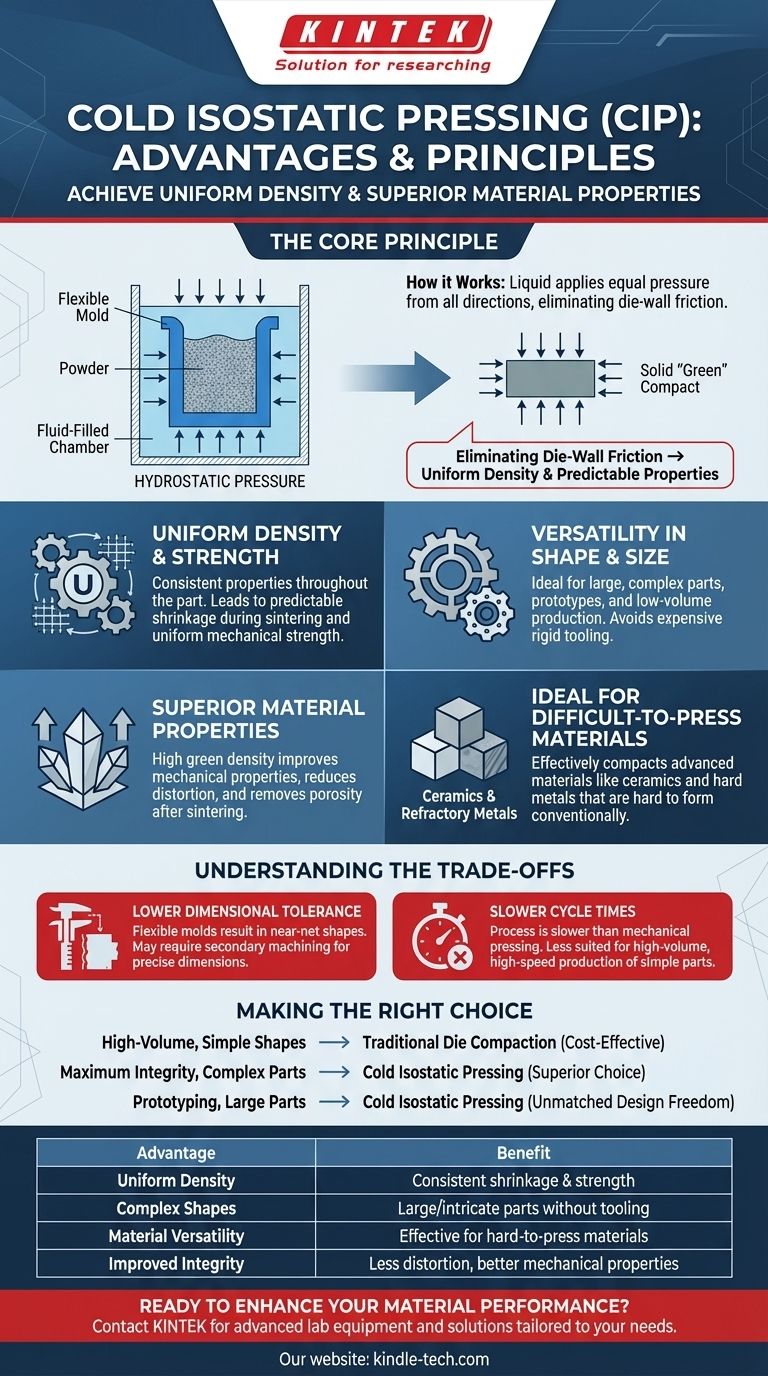

The Principle: Why Uniform Pressure Matters

The advantages of cold isostatic pressing stem directly from its unique method of compaction. Understanding this core principle is key to knowing when to apply it.

How Cold Isostatic Pressing Works

The process is conceptually simple. A powder is first enclosed in a flexible, airtight mold, typically made of an elastomer like rubber or polyurethane. This sealed mold is then submerged in a fluid-filled high-pressure chamber.

As the pressure of the fluid is increased, it acts uniformly on the entire surface of the flexible mold. This hydrostatic force compacts the powder particles together, forming a solid, dense "green" compact.

Eliminating Die-Wall Friction

In traditional uniaxial (one-direction) die pressing, the powder is pushed into a rigid metal die. As the powder moves, it creates significant friction against the die walls.

This friction prevents pressure from being transmitted evenly throughout the powder, resulting in a part with significant density variations. The areas farthest from the punch are often less dense than those closest to it.

CIP completely eliminates this die-wall friction, as the pressure is applied by a liquid directly and evenly to all surfaces.

Achieving Uniform Density and Strength

The direct result of uniform pressure is highly uniform density throughout the entire part, regardless of its size or complexity.

This uniformity is critical because it leads to predictable and consistent shrinkage during the subsequent sintering (firing) stage. It also results in uniform strength and consistent mechanical properties in the final component.

Key Manufacturing Advantages Explained

This fundamental principle gives rise to several distinct advantages in a manufacturing context.

Versatility in Shape and Size

Because CIP does not rely on expensive, rigid metal dies, its capabilities are greatly expanded. The process is ideal for prototyping and low-volume production where the cost of a hard die set would be prohibitive.

It also excels at producing very large or complex shapes that are impossible to form with traditional pressing, such as parts with undercuts or intricate internal cavities.

Superior Material Properties

The higher, more uniform green density achieved with CIP leads to a finished part with improved mechanical properties after sintering.

The process is excellent for densification and removing porosity, creating high-integrity preforms that exhibit very little distortion or cracking when fired.

Ideal for Difficult-to-Press Materials

Certain advanced materials, such as refractory metals, ceramics, and hard metals, do not compress or flow easily in traditional dies.

The uniform, all-encompassing pressure of CIP is highly effective at compacting these challenging powders into a dense, handleable preform for further processing.

Understanding the Trade-offs

While powerful, CIP is not the solution for every application. Its advantages come with inherent trade-offs that are critical to consider.

Lower Dimensional Tolerance

The use of a flexible, elastomeric mold means that the as-pressed "green" part will not have the tight dimensional tolerances of a component formed in a rigid steel die.

CIP parts are typically produced as near-net shapes, requiring secondary machining operations if precise dimensions are critical.

Slower Cycle Times

The process of loading the mold, sealing the pressure vessel, pressurizing, depressurizing, and unloading is inherently slower than the rapid action of a mechanical press.

For this reason, CIP is generally not suited for the high-volume, high-speed production of simple parts where cost per part is the primary driver.

Making the Right Choice for Your Goal

Selecting the right compaction method depends entirely on the technical requirements and business goals of your project.

- If your primary focus is high-volume production of simple shapes: Traditional die compaction is almost always more cost-effective due to its much faster cycle times.

- If your primary focus is maximum material integrity and performance: CIP is the superior choice for creating components with uniform density and predictable properties, especially with complex geometries.

- If your primary focus is prototyping or manufacturing large, complex parts: CIP provides unmatched design freedom and avoids the prohibitive cost and lead time of hard tooling.

Ultimately, choosing CIP is a strategic decision to prioritize material uniformity and design flexibility over raw production speed.

Summary Table:

| Advantage | Benefit |

|---|---|

| Uniform Density | Eliminates die-wall friction for consistent shrinkage and strength. |

| Complex Shapes | Ideal for large, intricate parts or prototypes without expensive tooling. |

| Material Versatility | Effective for hard-to-press materials like ceramics and refractory metals. |

| Improved Integrity | High green density leads to less distortion and better mechanical properties. |

Ready to enhance your material performance with Cold Isostatic Pressing?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your specific needs. Whether you're working with advanced ceramics, refractory metals, or complex component prototypes, our expertise ensures you achieve the uniform density and superior material integrity critical for your success.

Let us help you optimize your process. Contact our experts today to discuss how our solutions can benefit your laboratory.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is a cold press machine? A Guide to Uniform Powder Compaction Without Heat

- What is the function of a Cold Isostatic Press (CIP) in the fabrication of pouch-type all-solid-state batteries?

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- What is the cold isostatic press process? Create Uniform, High-Integrity Parts

- What is isostatic presses used for? Achieve Uniform Density and Superior Material Performance

- What is the significance of using a cold isostatic press (CIP) to achieve pressureless sintering in LLZO? Enhance Density

- How does a uniaxial cold press contribute to the preparation of sulfide solid electrolyte layers? Key to ASSB Density

- Why is an isostatic press used for solid electrolyte pellets? Achieve Maximum Density for Accurate Ionic Conductivity