At its core, an electric induction furnace offers a clean, precise, and highly efficient method for melting metals. Unlike traditional furnaces that burn fuel or use an electric arc to generate heat externally, an induction furnace uses the principle of electromagnetic induction to generate heat directly within the metal charge itself. This fundamental difference is the source of its most significant advantages in material quality, operational speed, and environmental safety.

The primary advantage of an electric induction furnace stems from its unique heating method. By generating heat inside the material, it eliminates combustion-related contamination and provides precise temperature control, resulting in higher quality melts, less material waste, and superior energy efficiency.

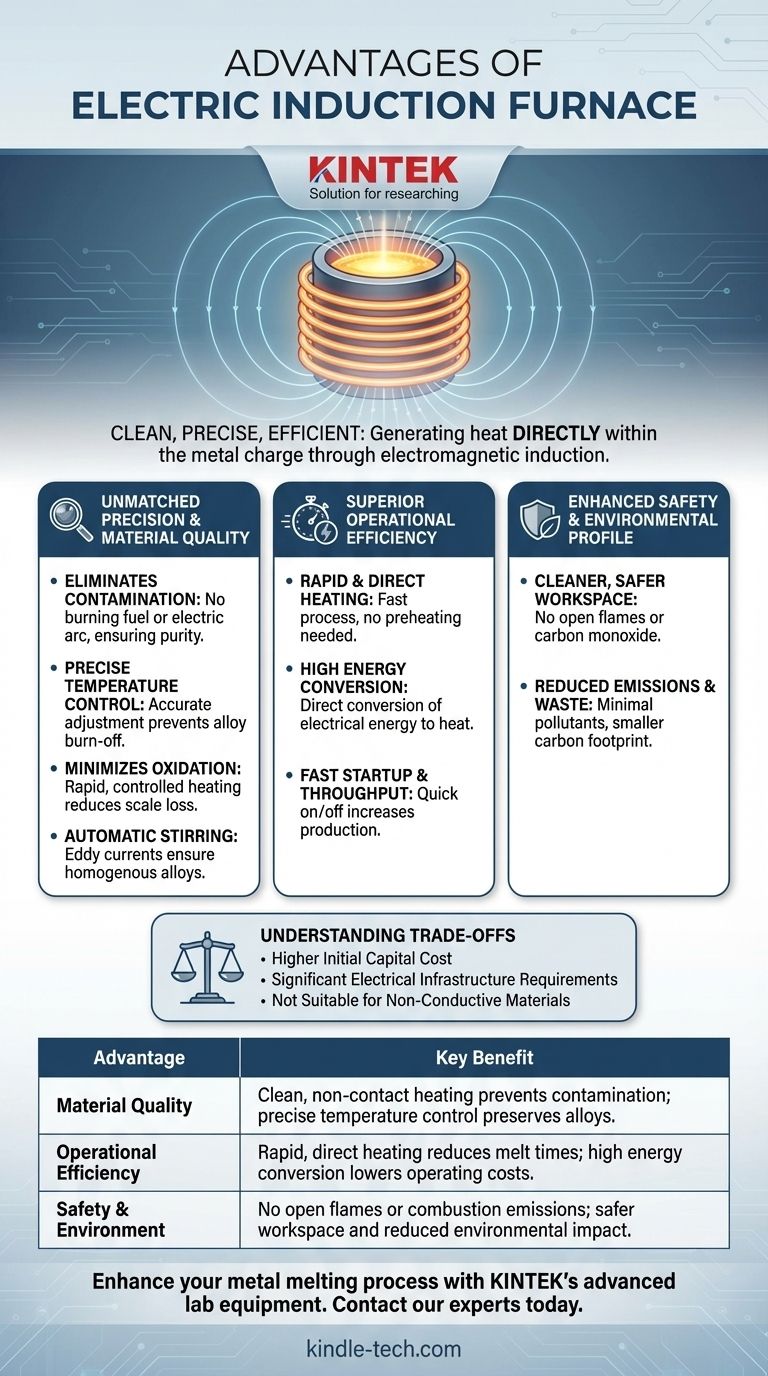

Unmatched Precision and Material Quality

The quality of the final product is often the most critical factor in metallurgical operations. Induction technology provides a level of control that is difficult to achieve with other methods.

How Induction Eliminates Contamination

Because an induction furnace does not rely on burning fuel or an electric arc, the melting process is inherently clean. There are no byproducts of combustion, such as gases or carbon, that can be introduced into the melt and contaminate the final metal.

Precise Temperature Control

The furnace's power can be adjusted with extreme accuracy, allowing for precise temperature control. This prevents the overheating that can cause valuable and sensitive alloying elements to burn off, ensuring the final chemical composition of the metal is exactly as specified.

Minimizing Oxidation and Decarburization

The rapid heating and controlled environment significantly reduce the amount of time the molten metal is exposed to oxygen. This results in far less oxidation (scale loss) and decarburization, saving valuable material that would otherwise be lost.

Automatic Stirring for Homogeneity

The electromagnetic field that heats the metal also creates a natural stirring action known as an eddy current effect. This ensures the molten bath is constantly mixed, leading to a perfectly uniform temperature and a homogenous distribution of alloys throughout the melt.

Superior Operational Efficiency

In a production environment, speed and cost-effectiveness are paramount. Induction furnaces excel by delivering energy exactly where it is needed.

Rapid and Direct Heating

Since heat is generated directly within the charge material, the process is incredibly fast and responsive. There is no need to first heat the furnace walls or crucible and wait for that heat to transfer to the metal, dramatically reducing melting times.

High Energy Conversion

Induction heating is highly efficient. Unlike fuel-fired furnaces that lose a significant amount of heat through exhaust flues and general radiation, an induction system converts a much higher percentage of its electrical energy directly into useful heat.

Fast Startup and Throughput

The ability to start and stop the furnace quickly without long warm-up or cool-down periods provides significant operational flexibility. This on-demand capability increases overall production throughput and reduces energy consumption during idle periods.

Understanding the Trade-offs

No technology is without its limitations. Acknowledging the trade-offs is essential for making an informed decision.

Initial Capital Cost

The initial purchase and installation cost of an induction furnace system, including its specialized power supply, can be higher than that of a traditional combustion furnace of a similar capacity.

Electrical Infrastructure Requirements

These furnaces have significant power requirements. A facility must have a robust and stable electrical supply capable of handling the high-power draw, which may necessitate infrastructure upgrades.

Material Constraints

Induction heating works by inducing a current in electrically conductive materials. It is therefore highly effective for most metals but is not suitable for melting non-conductive materials like ceramics or glass.

Enhanced Safety and Environmental Profile

Modern industrial operations face increasing pressure to improve both worker safety and environmental performance.

A Cleaner, Safer Workspace

By eliminating open flames and the combustion of fossil fuels, induction furnaces remove the risks associated with fuel storage and byproducts like carbon monoxide. This creates a significantly safer and healthier environment for workers.

Reduced Emissions and Waste

With no direct emissions from combustion, induction furnaces offer a much smaller carbon footprint. They generate minimal waste, smoke, and pollutants, simplifying environmental compliance and contributing to cleaner air.

Making the Right Choice for Your Application

Selecting the correct furnace technology depends entirely on your operational priorities.

- If your primary focus is high-purity alloys and minimal material loss: The clean, non-contact heating and precise control of induction technology make it the ideal choice to protect valuable materials.

- If your primary focus is production speed and energy efficiency: The rapid, direct heating of an induction furnace offers unmatched performance for high-throughput operations.

- If your primary focus is environmental compliance and worker safety: The flameless, low-emission nature of an induction furnace provides a clear advantage over traditional fuel-fired systems.

Ultimately, the electric induction furnace represents a strategic investment in quality, efficiency, and a cleaner operational future.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Quality | Clean, non-contact heating prevents contamination; precise temperature control preserves alloys. |

| Operational Efficiency | Rapid, direct heating reduces melt times; high energy conversion lowers operating costs. |

| Safety & Environment | No open flames or combustion emissions; safer workspace and reduced environmental impact. |

Ready to enhance your metal melting process with precision and efficiency? KINTEK specializes in advanced lab equipment, including electric induction furnaces, to meet the demanding needs of metallurgical laboratories. Our solutions deliver the high-purity results, operational speed, and safety standards your research requires. Contact our experts today to find the perfect furnace for your application and see how we can support your laboratory's success.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity