At its core, a hydraulic press offers the significant advantage of generating exceptionally high force within a compact, simple, and cost-effective design. This capability is paired with superior control and built-in overload protection, making it a versatile and reliable tool for a vast range of industrial and laboratory applications.

The fundamental advantage of a hydraulic press is not just the immense force it can generate, but its ability to apply that force with precision and control. This unique combination of power and finesse makes it superior for tasks requiring both strength and repeatability.

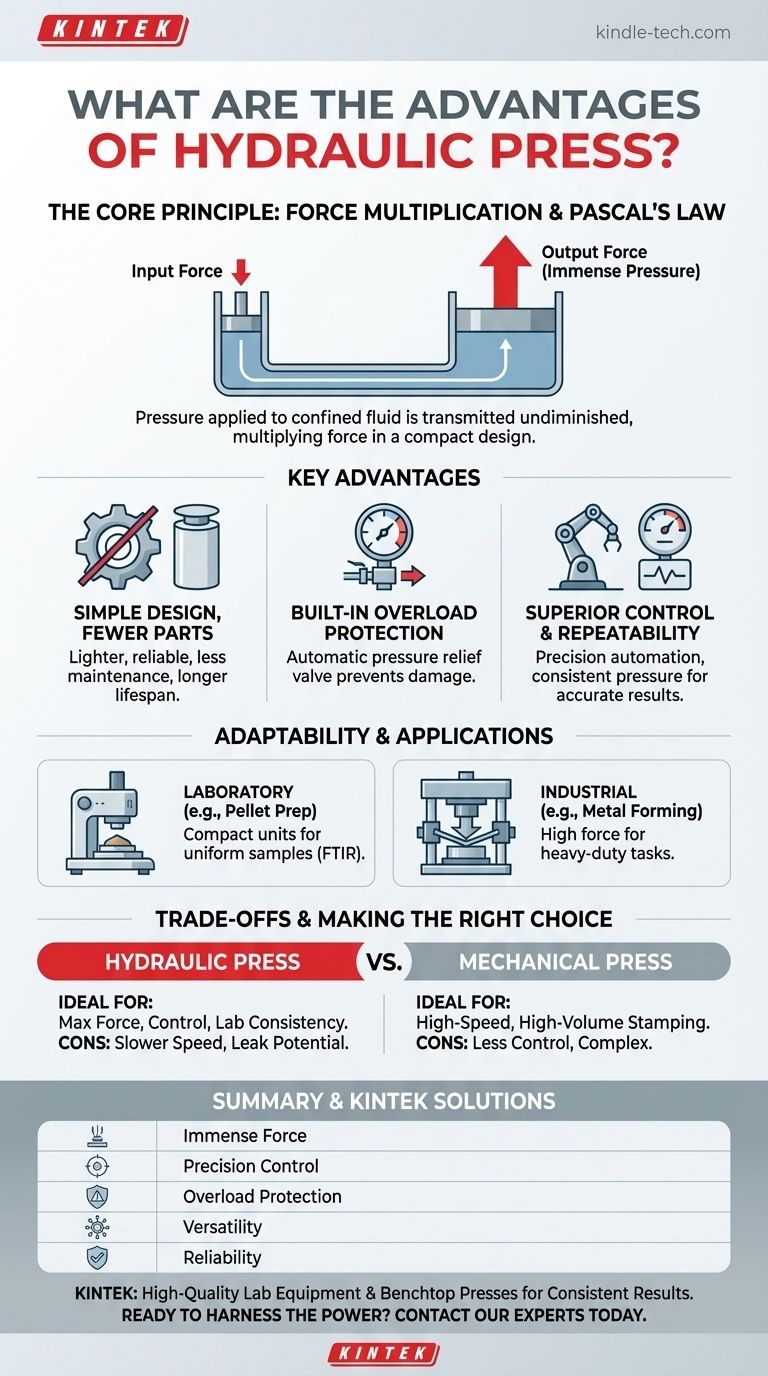

The Core Principle: Force Multiplication in a Compact Design

The primary benefits of a hydraulic press stem from its ingenious use of fluid dynamics. This allows for a mechanically simple machine that delivers disproportionately large outputs.

How Pascal's Law Enables Immense Pressure

A hydraulic press operates on Pascal's principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid.

By applying a small force to a small piston, the system generates immense pressure. This pressure then acts on a much larger piston, multiplying the initial force to produce the massive tonnage hydraulic presses are known for.

Simple Design, Fewer Parts

Compared to complex mechanical presses with gears, cranks, and flywheels, a hydraulic press has a very simple structure consisting mainly of cylinders, pistons, and hydraulic lines.

This simplicity leads to a lighter overall machine with fewer moving parts, which translates to higher reliability, less maintenance, and a longer operational lifespan.

Built-in Overload Protection

Every hydraulic system has a pressure relief valve. If the machine's force exceeds a set limit, this valve automatically opens, preventing damage to the machine or the workpiece.

This feature provides inherent, built-in overload protection that is much more difficult and expensive to implement in a mechanical press.

Superior Control and Repeatability

Beyond raw power, the control over that power is what truly sets the hydraulic press apart, especially in modern automated systems.

Precision Through Automation

Automatic hydraulic presses use electric controls to precisely manage the hydraulic valves. Once programmed, the machine can operate autonomously.

This allows for highly accurate and repeatable results, as the pressure and ram position are controlled by the system, not a human operator. This improves workflow and frees up technicians for other tasks.

Consistent Pressure Application

Many hydraulic presses, including smaller lab-scale models, feature a pressure gauge. This ensures the exact same load can be applied for every cycle.

This capability is critical in laboratory settings, such as creating uniform pellets for FTIR spectroscopy, where sample consistency is paramount for reliable testing. It is a stark contrast to manual hand presses, which lack a method for standardizing pressure.

Adaptability for Various Applications

The ability to control force, speed, and position makes hydraulic presses incredibly versatile. They are used for everything from heavy-duty metal forming to delicate assembly.

In laboratory environments, they are available as compact benchtop units that provide tons of force without taking up excessive space. Specialized versions, like hot presses with heated platens, further expand their utility.

Key Trade-offs and Considerations

While powerful and versatile, hydraulic presses are not the universal solution for every task. Understanding their limitations is key to making an informed decision.

Speed vs. Mechanical Presses

Hydraulic presses are generally slower than mechanical presses. For high-volume, high-speed applications like stamping simple parts, a mechanical press often provides a much higher cycle rate.

Potential for Hydraulic Fluid Leaks

As with any hydraulic system, there is a risk of fluid leaks from hoses, seals, or fittings. This requires diligent maintenance and can be a concern in cleanroom environments.

Noise and Power Consumption

The hydraulic pump motor runs throughout the machine's operation, which can generate more continuous noise and consume more energy at idle compared to a mechanical press that only draws significant power during the stroke.

Making the Right Choice for Your Application

Selecting the right press requires matching the machine's core strengths to your specific operational goal.

- If your primary focus is maximum force and control: The hydraulic press is ideal for deep drawing, molding, forging, and any task that demands immense, controllable pressure over a full stroke.

- If your primary focus is high-speed production: A mechanical press is often the better choice for high-volume, repetitive stamping or blanking operations where raw speed is the priority.

- If your primary focus is lab-scale consistency: A benchtop hydraulic press offers unparalleled repeatability and precision for sample preparation compared to any manual method.

Ultimately, choosing a hydraulic press is a decision to prioritize controllable power and versatility for your application.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Immense Force | Generates high tonnage from a compact, simple design. |

| Precision Control | Automated systems ensure accurate, repeatable results. |

| Overload Protection | Built-in pressure relief valve prevents machine damage. |

| Versatility | Suitable for heavy-duty forming to delicate lab work. |

| Reliability | Fewer moving parts mean less maintenance and longer life. |

Ready to harness the power and precision of a hydraulic press for your lab?

KINTEK specializes in high-quality lab equipment, including benchtop hydraulic presses designed for reliable sample preparation and consistent results. Whether you need to create uniform pellets for FTIR spectroscopy or require a robust press for your R&D workflow, our solutions deliver the control and durability you need.

Contact our experts today to find the perfect hydraulic press for your laboratory's specific requirements!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy