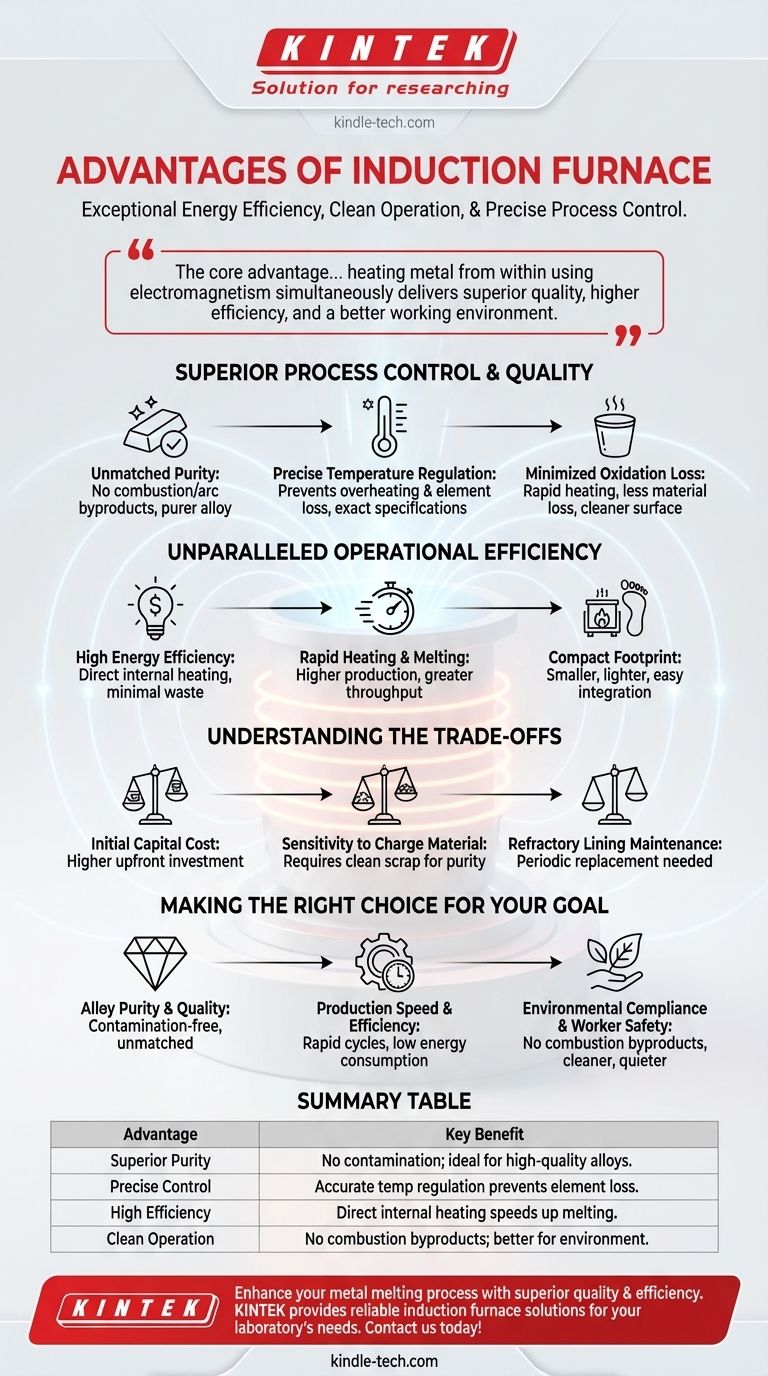

In short, the primary advantages of an induction furnace are its exceptional energy efficiency, clean operation, and precise process control. Unlike traditional furnaces that rely on burning fuel or electric arcs, an induction furnace uses an electromagnetic field to generate heat directly within the metal itself, resulting in a faster, cleaner, and more controllable melting process.

The core advantage of induction technology is not just one feature, but how its fundamental principle—heating metal from within using electromagnetism—simultaneously delivers superior quality, higher efficiency, and a better working environment.

Superior Process Control and Quality

The main driver for adopting an induction furnace is often the pursuit of higher-quality metal. The heating method directly prevents common issues found in other furnace types.

Unmatched Purity

Because an induction furnace does not use combustion or an electric arc, there are no byproducts like gas or carbon that can be introduced into the melt.

The heat is generated within the charge material, eliminating contact with external heating elements. This is critical for applications where even minor contamination is unacceptable, resulting in a purer final alloy.

Precise Temperature Regulation

The power supplied to the induction coil can be controlled with extreme accuracy. This allows for precise regulation of the metal's temperature.

This level of control is essential for preventing the overheating and loss of valuable and volatile alloying elements, ensuring the final chemical composition of the metal meets exact specifications.

Minimized Oxidation Loss

Induction heating is incredibly fast, which significantly reduces the time the molten metal is exposed to the atmosphere.

This rapid process, combined with precise temperature control, minimizes oxidation and decarburization. The result is less material loss (scale) and lower costs for forging dies, as the metal surface is cleaner.

Unparalleled Operational Efficiency

Induction furnaces are designed to maximize throughput and minimize waste, directly impacting the bottom line of any melting operation.

High Energy Efficiency

The heat is generated directly inside the metal being melted. This means very little energy is wasted heating the furnace walls or the surrounding environment.

This method is far more energy-efficient than combustion furnaces, where a significant portion of heat is lost through exhaust gases and general radiation.

Rapid Heating and Melting

The direct transfer of energy allows for exceptionally fast melting and heating cycles.

This speed translates directly to higher production efficiency and greater throughput, allowing foundries to process more material in less time.

Compact Footprint

Compared to other furnace types with similar capacity, induction furnaces are often smaller and lighter. This makes them easier to integrate into existing facilities and more flexible for plant layout design.

Understanding the Trade-offs

While highly advantageous, induction furnaces are not a universal solution. Understanding their limitations is key to making an informed decision.

Initial Capital Cost

The technology behind induction furnaces, including the power supply and water-cooled copper coils, generally results in a higher upfront investment compared to simpler combustion furnaces.

Sensitivity to Charge Material

The process itself does not refine the metal. Any contaminants on the scrap material, such as oil, paint, or excessive rust, will be introduced into the melt. Achieving the highest purity requires using clean, well-sorted charge material.

Refractory Lining Maintenance

The crucible or refractory lining that holds the molten metal is subject to intense thermal and electromagnetic stress. This lining wears over time and requires regular monitoring and periodic replacement, which is a key operational cost.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on your operational priorities.

- If your primary focus is alloy purity and quality: The contamination-free, precisely controlled environment of an induction furnace is unmatched.

- If your primary focus is production speed and energy efficiency: The rapid heating cycles and low energy consumption offer significant advantages for high-throughput foundries.

- If your primary focus is environmental compliance and worker safety: The lack of combustion byproducts and a cleaner, quieter operating environment make induction a superior choice.

Ultimately, the induction furnace provides a modern, integrated solution that excels at balancing metallurgical quality with operational and environmental responsibility.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Purity | No contamination from combustion or arcs; ideal for high-quality alloys. |

| Precise Control | Accurate temperature regulation prevents loss of volatile elements. |

| High Efficiency | Direct internal heating minimizes energy waste and speeds up melting. |

| Clean Operation | No combustion byproducts; better for the environment and worker safety. |

Ready to enhance your metal melting process with superior quality and efficiency?

KINTEK specializes in advanced lab equipment and consumables, providing reliable induction furnace solutions tailored to your laboratory's needs. Our expertise ensures you achieve precise temperature control, high purity melts, and significant energy savings.

Contact us today to discuss how our induction furnaces can optimize your operations and deliver the metallurgical quality your research demands!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the different heating methods for brazing? A Guide to Choosing the Right Process

- What is the difference between induction furnace and electric furnace? Uncover the Best Heating Method for Your Lab

- What is the highest temperature for an induction furnace? Unlocking 2000°C for High-Purity Melting

- How hot can an induction furnace get? Unlocking Temperatures Up to 2000°C

- What are the primary functions of an induction furnace lining? Essential Safety & Efficiency Roles in Metal Melting

- Can induction furnace melt aluminum? Achieve Fast, Clean Melting for Your Lab

- Why use vacuum induction melting and water atomization for Cu-Re powders? Achieve Purity and High Density.

- What are the advantages of vacuum induction melting? Achieve Ultimate Purity & Precision for High-Performance Alloys