While your question mentions ion beam assisted evaporation, the common and direct comparison is typically between electron beam (e-beam) evaporation and standard thermal evaporation. E-beam evaporation provides significant advantages, including the ability to deposit materials with very high melting points, achieve higher film purity by minimizing crucible contamination, and produce denser, more uniform coatings with greater control over the deposition rate.

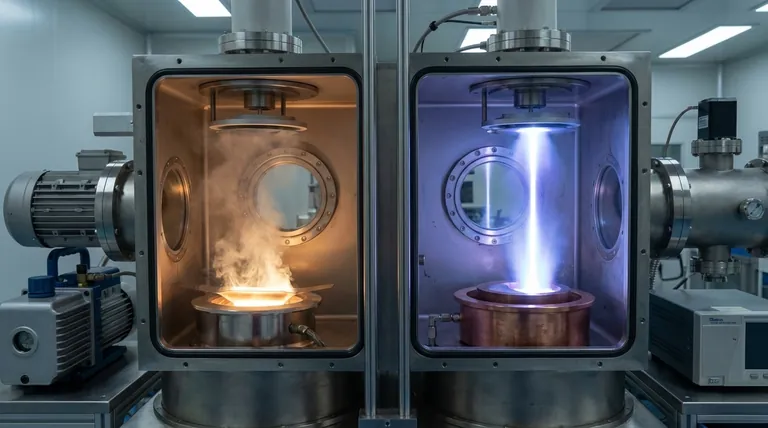

E-beam evaporation uses a focused beam of electrons to deliver precise, intense energy directly to the source material. This fundamental difference makes it a more versatile and higher-performance technique than thermal evaporation, which relies on resistively heating an entire boat or crucible.

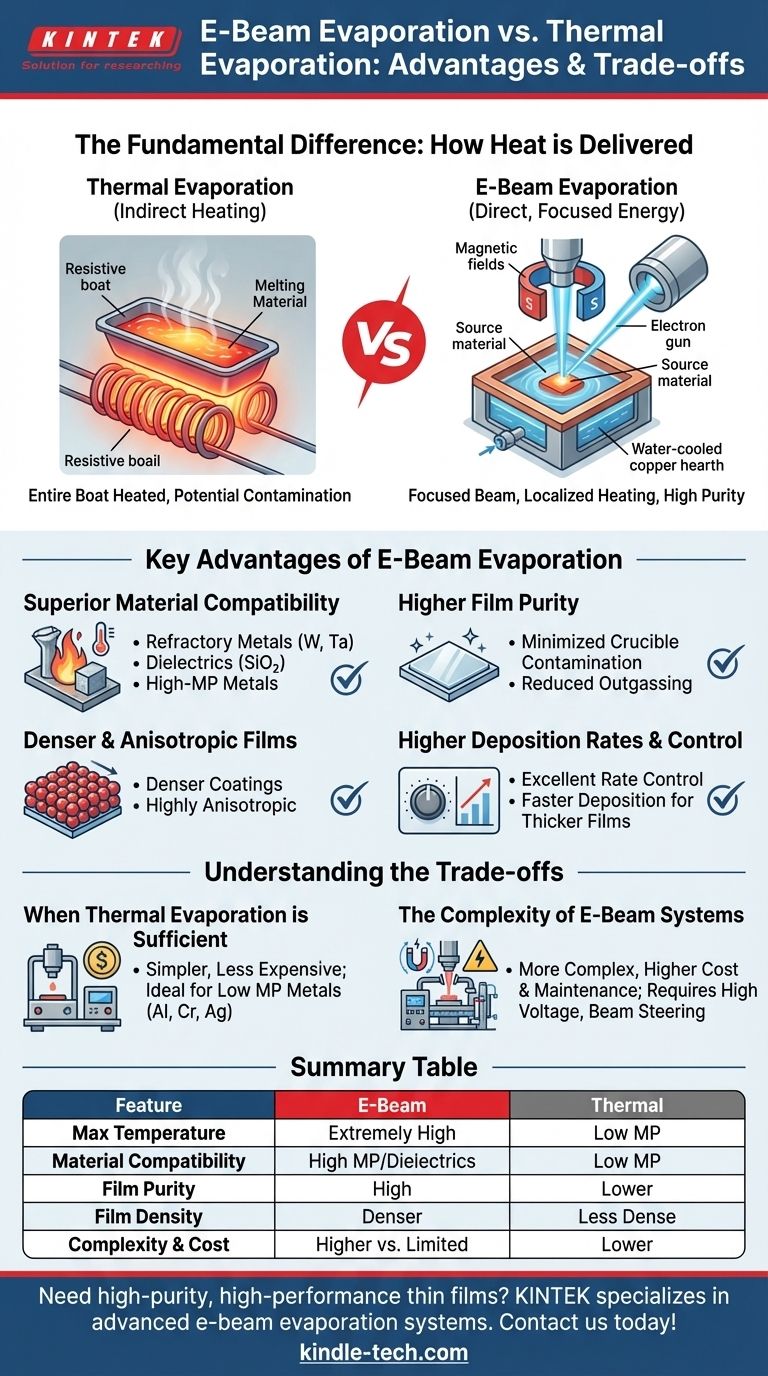

The Fundamental Difference: How Heat is Delivered

The advantages of e-beam evaporation stem directly from its more advanced method of heating the source material. Understanding this is key to choosing the right process.

Thermal Evaporation: Indirect Heating

In thermal evaporation, an electrical current is passed through a resistive "boat" or crucible containing the source material.

This boat heats up significantly, which in turn melts and then evaporates the material inside it. The entire crucible becomes a source of heat and potential contamination.

E-Beam Evaporation: Direct, Focused Energy

E-beam evaporation uses a high-energy beam of electrons, guided by magnetic fields, to strike the surface of the source material directly.

This concentrates an immense amount of energy onto a very small spot. This direct heating is far more efficient and localized, vaporizing the material without significantly heating the surrounding water-cooled copper hearth.

Key Advantages of E-Beam Evaporation

This direct heating method gives e-beam evaporation several distinct advantages over the thermal process.

Superior Material Compatibility

Because it can generate extremely high temperatures, e-beam evaporation can deposit materials that are impossible for thermal evaporators to handle.

This includes refractory metals like tungsten and tantalum, and dielectrics or oxides like silicon dioxide (SiO₂). It is also excellent for high-melting-point metals like platinum and gold.

Higher Film Purity

In e-beam evaporation, the heating is confined to the source material itself. The water-cooled copper crucible remains relatively cool.

This dramatically reduces the risk of impurities from the crucible melting or outgassing and contaminating the deposited thin film. Thermal evaporation, by contrast, heats the entire crucible, which can introduce contaminants.

Denser and More Anisotropic Films

E-beam evaporation generally produces denser thin film coatings compared to those from thermal evaporation.

The line-of-sight nature of the process also results in highly anisotropic coatings, meaning the atoms arrive at the substrate from a single direction. This is highly beneficial for certain microfabrication processes like lift-off.

Higher Deposition Rates and Control

The ability to precisely control the electron beam's power allows for excellent control over the deposition rate. This is critical, as the rate can significantly influence the final properties of the film.

E-beam systems can also achieve much higher deposition rates than thermal evaporation, making the process more efficient for thicker films.

Understanding the Trade-offs

Despite its advantages, e-beam evaporation is not always the necessary choice. The primary trade-off is complexity and cost.

When Thermal Evaporation is Sufficient

Thermal evaporation systems are mechanically simpler and generally less expensive than e-beam systems.

For materials with low melting temperatures, such as aluminum, chromium, or silver, thermal evaporation is often a perfectly adequate, cost-effective, and straightforward solution.

The Complexity of E-Beam Systems

E-beam evaporators are more complex machines. They require high-voltage power supplies, magnetic fields for beam steering, and more sophisticated control systems. This added complexity increases both the initial cost and the operational maintenance requirements.

Making the Right Choice for Your Application

Selecting the correct deposition technique requires matching the process capabilities to your material requirements and desired film quality.

- If your primary focus is depositing high-melting-point materials or achieving maximum film purity: E-beam evaporation is the definitive choice for its temperature range and reduced contamination.

- If your primary focus is simplicity and cost-effectiveness for common, low-temperature metals: Thermal evaporation is often the most practical and efficient solution.

- If your primary focus is creating dense, highly controlled films for advanced applications: E-beam evaporation provides the superior control over deposition rate and film structure.

Ultimately, the right choice is dictated by the specific demands of your material and the performance you require from the final thin film.

Summary Table:

| Feature | E-Beam Evaporation | Thermal Evaporation |

|---|---|---|

| Max Temperature | Extremely High (>3000°C) | Limited (lower melting points) |

| Material Compatibility | Refractory metals, oxides (e.g., SiO₂) | Lower melting point metals (e.g., Al, Ag) |

| Film Purity | High (minimized crucible contamination) | Lower (potential crucible outgassing) |

| Film Density | Denser coatings | Less dense coatings |

| Process Complexity & Cost | Higher | Lower |

Need to deposit high-purity, high-performance thin films? KINTEK specializes in advanced lab equipment, including e-beam evaporation systems, to meet your most demanding material science challenges. Our experts can help you select the right technology for your specific application, ensuring optimal film quality and process efficiency. Contact our team today to discuss your project requirements and discover how our solutions can enhance your research or production outcomes.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is vacuum thermal evaporation? A Guide to High-Purity Thin Film Deposition

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab