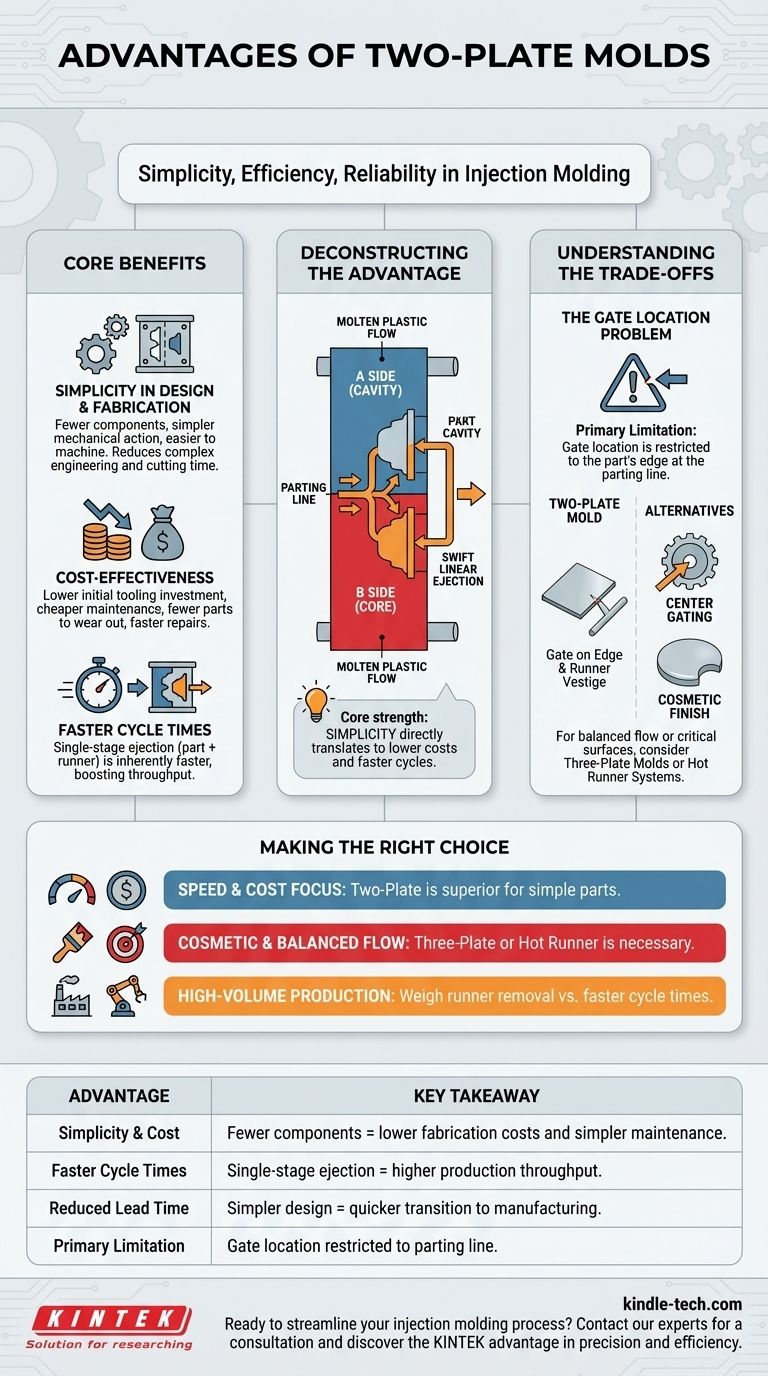

In the world of injection molding, the two-plate mold stands as the foundational design due to its straightforward efficiency and reliability. Its primary advantages are a simple, cost-effective construction, faster production cycle times compared to more complex designs, and a significantly shorter lead time from design to manufacturing.

The core strength of a two-plate mold lies in its simplicity. This fundamental design translates directly into lower fabrication costs and faster production cycles, making it the most efficient choice for parts where gating can be managed at the parting line.

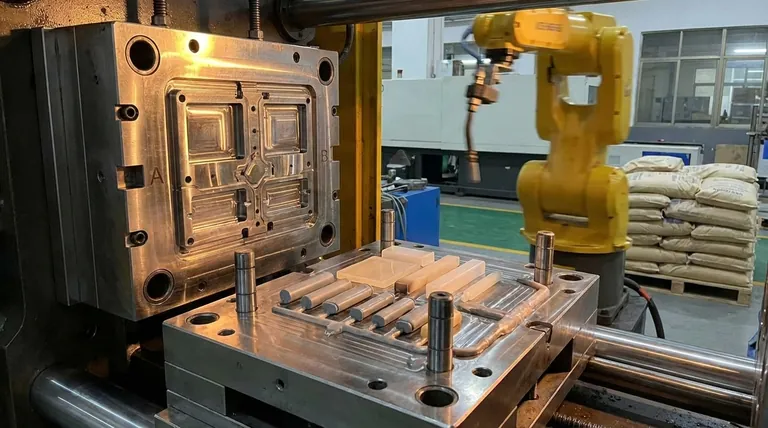

Deconstructing the Two-Plate Mold Advantage

A two-plate mold is constructed from two main halves, the "A" side (cavity) and the "B" side (core), which meet at a single plane known as the parting line. Understanding why this simple structure is so beneficial is key to leveraging it effectively.

Simplicity in Design and Fabrication

The mold's design consists of just two primary plates that separate. This means fewer components, a simpler mechanical action, and less complex engineering.

This simplicity makes the mold easier and faster to machine. Fewer intricate features and moving parts reduce programming, setup, and cutting time, which is a major factor in manufacturing costs.

The Impact on Cost-Effectiveness

Directly tied to its simple design, the cost-effectiveness of a two-plate mold is its most significant advantage. The reduced machining complexity and lower component count drastically cut down on the initial tooling investment.

Furthermore, maintenance is simpler and less expensive over the life of the tool. With fewer things that can wear out or break, troubleshooting and repairs are faster and less frequent.

Faster Cycle Times for Higher Throughput

The molding cycle consists of closing the mold, injecting plastic, cooling, and ejecting the part. In a two-plate mold, the opening and ejection happen in one swift, linear motion.

The part is ejected along with its attached runner system (the channels that deliver the plastic). This single-stage opening is inherently faster than a three-plate mold, which requires an additional movement to separate the runner before part ejection, adding seconds to every cycle time.

Reduced Lead Time from Concept to Production

The combination of simpler design and faster fabrication directly results in a shorter lead time. This means you can get your part into production more quickly, which is a critical advantage in fast-moving markets.

Understanding the Trade-offs: The Gate Location Problem

While highly efficient, the two-plate mold's primary limitation is its lack of flexibility in gate location. This trade-off is the single most important factor when deciding if it's the right choice for your part.

The Inflexible Gating Requirement

In a standard two-plate mold, the gate—the small opening where molten plastic enters the part cavity—must be located on the part's edge, directly at the parting line.

This is because the runner system that feeds the gate resides on the parting line's surface. There is no mechanism to route the plastic to the center or top of the part.

The Runner System Stays Attached

When the part is ejected, the solidified runner and sprue are ejected with it. This requires a secondary operation to separate the runner from the final part.

This separation can be done manually by an operator or through automation, but it adds a step to the process. It also leaves a gate vestige, or mark, on the edge of the part, which may not be acceptable for cosmetic surfaces.

When a Two-Plate Mold is Not the Answer

If your part requires a gate in the center for balanced filling (like a gear or a round lid), a two-plate mold is not suitable. Similarly, if the cosmetic appearance of the part's edge is critical and cannot have a gate mark, you must consider an alternative.

These applications often demand a three-plate mold or a hot runner system, which are designed specifically to overcome the gate location limitations of the two-plate design, albeit at a higher cost and complexity.

Making the Right Choice for Your Project

Selecting the correct mold type is a balance between part requirements, production volume, and budget. The two-plate mold is a powerful tool when used for the right application.

- If your primary focus is cost and speed on simple parts: The two-plate mold is almost always the superior choice due to its low tooling cost and fast cycle time.

- If your primary focus is cosmetic finish or balanced flow: A three-plate or hot runner system is necessary to control the gate location and avoid blemishes on critical surfaces.

- If your primary focus is high-volume, automated production: Weigh the cost of secondary runner-removal automation against the faster cycle time of a two-plate mold; for some parts, it remains the most efficient path.

By understanding these core principles, you can select the right tool for your manufacturing goal, ensuring efficiency and quality from the start.

Summary Table:

| Advantage | Key Takeaway |

|---|---|

| Simplicity & Cost | Fewer components mean lower fabrication costs and simpler maintenance. |

| Faster Cycle Times | Single-stage ejection leads to higher production throughput. |

| Reduced Lead Time | Simpler design allows for a quicker transition from design to manufacturing. |

| Primary Limitation | Gate location is restricted to the parting line, which may not suit all part designs. |

Ready to streamline your injection molding process?

At KINTEK, we specialize in providing the right lab equipment and consumables to support your manufacturing and R&D efforts. Whether you're prototyping a new part or optimizing for high-volume production, our expertise can help you select the most efficient and cost-effective tooling solutions.

Let's discuss how a two-plate mold can benefit your specific project. Contact our experts today for a consultation and discover the KINTEK advantage in precision and efficiency.

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Cylindrical Press Mold for Lab Applications

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is mould in manufacturing? Unlock Mass Production with Precision Tooling

- What are molds used for? Unlock Mass Production of Precision Parts

- What are the factors affecting molding? Master the 4 Keys to Perfect Plastic Parts

- What is the function of high-strength pressure molds for nanostructured copper powders? Achieve High Purity Densification

- Why is a Cold Isostatic Press (CIP) Required for NaSICON? Achieve Maximum Green Density and Ionic Conductivity