At its core, an electric arc furnace (EAF) is a high-powered system designed to melt steel scrap and other metallic inputs using an intense electric arc. The fundamental components include a steel shell lined with heat-resistant material, a set of large graphite electrodes to conduct electricity, a roof that can be moved for loading, and a tilting mechanism to pour the molten metal.

The essential purpose of an electric arc furnace is not just to contain heat, but to act as a focused delivery system for massive amounts of electrical energy, creating a contained, high-temperature arc—like a man-made lightning bolt—to melt a metal charge with precision and efficiency.

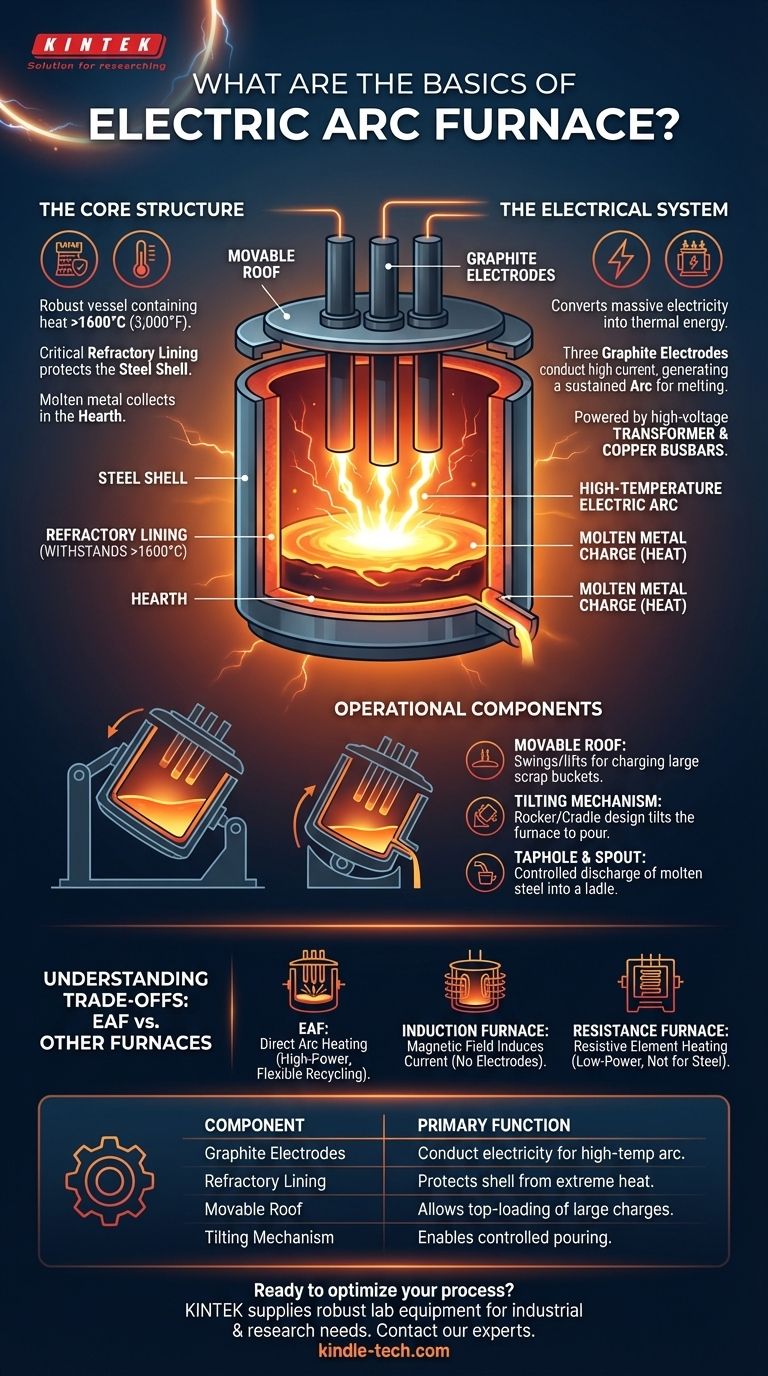

The Core Structure: Containing the Heat

The primary structure of the EAF is a robust vessel designed to withstand extreme temperatures exceeding 1,600°C (3,000°F).

The Shell and Sidewalls

The furnace itself is a large, cylindrical steel shell. This outer casing provides the structural integrity for the entire vessel.

The Refractory Lining

Inside the shell, a thick layer of refractory bricks or other heat-resistant material forms the lining. This critical layer protects the steel shell from the intense heat of the molten metal and the electric arc.

The Hearth

The hearth is the bowl-shaped bottom of the furnace. This is where the molten metal, known as the "heat" or "melt," collects before it is poured.

The Electrical System: Generating the Arc

The true work of the EAF is done by its powerful electrical system, which converts electricity into thermal energy.

The Graphite Electrodes

Three large graphite electrodes are the heart of the system. These cylindrical rods, often over two feet in diameter, are lowered through holes in the furnace roof.

A massive electric current is passed through the electrodes, and they are lowered close to the metal charge. The electricity then jumps the gap, creating a sustained electric arc that transfers immense heat directly to the metal, causing it to melt.

The Power Supply System

This system requires an extremely powerful transformer to step down high-voltage electricity from the grid to the lower-voltage, high-current power needed for the arc. This current is delivered to the electrodes via heavy, water-cooled copper busbars.

Operational Components: Loading and Pouring

The furnace is not a static vessel; it is a dynamic piece of machinery with components designed for loading raw materials and discharging finished liquid steel.

The Roof

The roof of the furnace is also lined with refractory material and can be swung aside or lifted off completely. This allows large buckets of steel scrap (the "charge") to be dropped directly into the furnace.

The Tilting Mechanism

The entire furnace shell is mounted on a rocker or cradle. This mechanism uses powerful hydraulic or electric drives to tilt the furnace forward, allowing the molten steel to be poured out in a controlled manner.

The Taphole and Spout

A taphole is a dedicated opening in the furnace wall. When the furnace is tilted, molten metal flows through this hole and down a refractory-lined spout (or gutter) into a ladle for transport.

Understanding the Trade-offs: EAF vs. Other Furnaces

The term "electric furnace" can be confusing. The EAF's method of direct arc heating is fundamentally different from other electric heating technologies.

EAF vs. Induction Furnace

An induction furnace also uses electricity but operates on a different principle. It uses an induction coil to generate a powerful magnetic field that induces electrical currents within the metal itself, causing it to heat up and melt from the inside out. It does not use electrodes or an arc.

EAF vs. Resistance Furnace

A resistance furnace, such as one found in a home's heating system, works by passing electricity through a resistive heating element, causing it to glow red hot. Heat is then transferred to the surrounding air or material via radiation and convection. This is a much lower-power application and is not suitable for melting steel.

Making the Right Choice for Your Goal

Understanding the EAF's design is about recognizing how each part contributes to its primary function: efficient, large-scale metal recycling.

- If your primary focus is steel recycling: The EAF's top-loading design and direct-arc melting make it the most flexible and efficient technology for turning scrap metal into new, high-quality steel.

- If your primary focus is the core principle: Remember that the EAF's magic lies in converting electrical energy into a powerful arc, a method that transfers heat far more intensely than simply heating an element.

- If your primary focus is operational mechanics: The key components to understand are the movable roof for charging and the tilting mechanism for tapping the molten steel.

Ultimately, the electric arc furnace is a carefully engineered system where each component serves the singular goal of safely mastering immense electrical power to melt and recycle metal.

Summary Table:

| Component | Primary Function |

|---|---|

| Graphite Electrodes | Conduct electricity to create a high-temperature arc for melting. |

| Refractory Lining | Protects the steel shell from extreme heat (exceeding 1600°C). |

| Movable Roof | Allows for top-loading of large scrap metal charges. |

| Tilting Mechanism | Enables controlled pouring of molten steel into a ladle. |

Ready to optimize your metal melting or recycling process? The principles of the electric arc furnace demonstrate the power of precise, high-temperature equipment. At KINTEK, we specialize in supplying robust lab equipment and consumables for demanding industrial and research applications. Whether you're scaling up operations or need reliable tools for material testing, our experts can help. Contact KINTEK today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vertical Laboratory Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How is temperature controlled in a furnace? Mastering Precise Thermal Management

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?