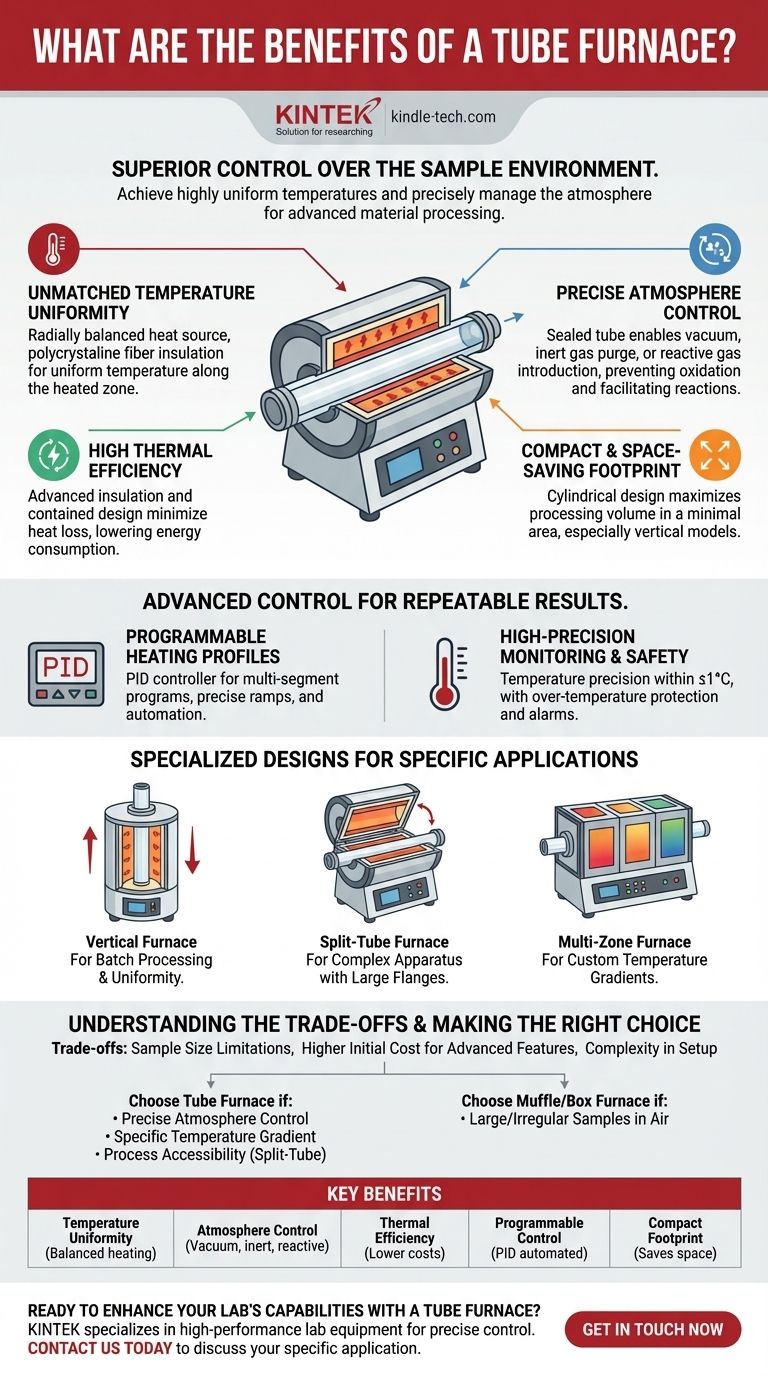

At its core, a tube furnace offers superior control over the sample environment. Its primary benefits are the ability to achieve highly uniform temperatures and to precisely manage the atmosphere, from creating a vacuum to introducing specific reactive or inert gases, making it an indispensable tool for advanced material processing.

The true advantage of a tube furnace is not just its ability to heat a sample, but its capacity to create a highly controlled, repeatable, and isolated micro-environment. This makes it the superior choice for processes where temperature precision and atmospheric conditions are critical to the outcome.

The Core Advantages of a Tube Furnace Design

A tube furnace's unique cylindrical structure is the source of its most significant benefits, setting it apart from more general-purpose equipment like muffle or box furnaces.

Unmatched Temperature Uniformity

The heating elements in a tube furnace are arranged around the central tube, creating a radially balanced heat source. This design, often enhanced with advanced insulation materials like polycrystalline fiber, results in an exceptionally uniform temperature field along the heated zone. This consistency is critical for reliable and repeatable material processing.

Precise Atmosphere Control

This is arguably the most important advantage. The sealed tube allows you to completely control the gaseous environment around your sample. You can purge the air and introduce an inert gas to prevent oxidation, create a vacuum for degassing, or introduce reactive gases to facilitate a specific chemical reaction. This level of control is simply not possible in a standard muffle furnace.

High Thermal Efficiency

Modern tube furnaces are built with mature technology focused on efficiency. The contained design and high-quality insulation minimize heat loss to the surrounding environment. This results in lower energy consumption and higher thermal efficiency, saving significant operational costs over the long term.

Compact and Space-Saving Footprint

For the processing volume they provide, tube furnaces have a remarkably compact design. This is particularly beneficial in crowded laboratories or production facilities where floor space is at a premium. Vertical tube furnaces, in particular, maximize processing capability while minimizing the required footprint.

Advanced Control for Repeatable Results

Modern tube furnaces have evolved from simple heaters into sophisticated, programmable instruments designed for precision and automation.

Programmable Heating Profiles

Most tube furnaces are equipped with a PID (Proportional-Integral-Derivative) controller, which enables highly precise temperature management. This system allows users to set up complex, multi-segment programs with defined ramps for temperature rise and fall, ensuring processes can be automated and repeated perfectly.

High-Precision Monitoring and Safety

These systems offer exceptional temperature control precision, often within ±1°C. They are also equipped with critical safety features, such as over-temperature protection and alarms for thermocouple failure, which protect both the sample and the equipment.

Specialized Designs for Specific Applications

The basic tube furnace design has been adapted into several specialized forms to meet unique processing challenges.

Vertical Furnaces: For Batch Processing & Uniformity

Orienting the tube vertically simplifies the loading and unloading of samples, especially for batch processing. This orientation can also leverage gravity and natural convection to further enhance temperature uniformity along the tube's length.

Split-Tube Furnaces: For Complex Apparatus

A split-tube furnace is hinged, allowing it to open into two halves. This feature is essential when the work tube has large flanges or fittings on the ends that would make it impossible to slide into a standard, non-split furnace.

Multi-Zone Furnaces: For Custom Temperature Gradients

For highly advanced applications like crystal growth or chemical vapor deposition, multi-zone furnaces are used. These feature multiple, independently controlled heating zones along the tube's length, allowing the user to create a precise, tailored temperature gradient or profile.

Understanding the Trade-offs

While powerful, tube furnaces are not the universal solution for all heating applications. Understanding their limitations is key to making an informed decision.

Sample Size Limitations

The most obvious trade-off is sample size. The diameter of the tube inherently restricts the dimensions of the material you can process. For large or bulky items, a box or muffle furnace is often a more practical choice.

Higher Initial Cost for Advanced Features

While a basic tube furnace can be affordable, models with advanced features like multi-zone control, high-vacuum compatibility, or specialized gas handling systems represent a more significant capital investment than simpler furnaces.

Complexity in Setup

Achieving precise atmospheric control requires more than just the furnace itself. The setup often involves external gas lines, flow controllers, and vacuum pumps, adding a layer of complexity compared to a simple "plug-and-play" muffle furnace.

Making the Right Choice for Your Process

Selecting the right heating equipment depends entirely on the specific requirements of your material and process.

- If your primary focus is precise atmosphere control: A tube furnace is the definitive choice for any process requiring an inert, reactive, or vacuum environment.

- If your primary focus is creating a specific temperature gradient: A multi-zone tube furnace offers unparalleled control for complex thermal profiles in material synthesis or crystal growth.

- If your primary focus is heating large or irregularly shaped samples in air: A muffle or box furnace is a more practical and cost-effective solution.

- If your primary focus is process accessibility for complex reactor tubes: A split-tube furnace provides the control of a tube design with the critical ability to accommodate non-standard apparatus.

Ultimately, choosing a tube furnace is a decision to prioritize control and precision over sheer volume.

Summary Table:

| Key Benefit | Description |

|---|---|

| Temperature Uniformity | Radially balanced heating for consistent results. |

| Atmosphere Control | Create vacuum, inert, or reactive gas environments. |

| Thermal Efficiency | Energy-efficient design lowers operational costs. |

| Programmable Control | PID controllers for automated, repeatable processes. |

| Compact Footprint | Saves valuable lab space, especially vertical models. |

Ready to enhance your lab's capabilities with a tube furnace?

KINTEK specializes in high-performance lab equipment, including tube furnaces designed for precise temperature and atmosphere control. Whether your research requires uniform heating, inert gas environments, or complex programmable profiles, our solutions deliver the reliability and precision you need.

Contact us today to discuss your specific application and find the perfect furnace for your laboratory. Let KINTEK be your partner in achieving superior material processing results.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How hot does a quartz test tube get? Unlock Superior Heat Resistance for Your Lab

- Is quartz chemically reactive? The Hidden Danger of Freshly Fractured Dust

- Why is vacuum sealing in a quartz tube required for Na3PS4 synthesis? Ensure High Ionic Conductivity and Purity

- Why are quartz glass tube reactors preferred for microwave-driven hydrogen production? Boost Your Efficiency

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- What is the purpose of using high-temperature muffle or tube furnaces after incipient wetness impregnation of catalysts?

- What is the difference between a muffle furnace and a tube furnace? Choose the Right High-Temp Tool

- Why are quartz tube vacuum sealing and getters used during high-temperature annealing of stainless steel? Guard Purity