At their core, chemical deposition processes are a family of techniques used to create a solid thin film on a surface through a controlled chemical reaction. The primary methods are Chemical Vapor Deposition (CVD), where gaseous precursors react on a substrate, and liquid-phase methods like Chemical Solution Deposition (CSD) and plating, which use chemical solutions. These processes are distinct from physical deposition, which transfers material without a chemical change.

The critical distinction between chemical deposition methods is not the chemicals themselves, but the phase of the precursor—gas or liquid—used to deliver them. Your choice between them will be a trade-off between film quality, deposition temperature, and process complexity.

The Fundamental Principle: From Chemical to Solid

All deposition techniques aim to build a material layer by layer. The key difference between chemical and physical methods lies in how that material arrives and forms.

The "Chemical" in Chemical Deposition

Chemical deposition involves a two-step process. First, a chemical precursor, a compound containing the atoms you want to deposit, is delivered to a substrate. Second, energy (usually heat) is introduced to trigger a chemical reaction, causing the precursor to decompose and form a new, solid thin film on the substrate's surface.

Contrast with Physical Vapor Deposition (PVD)

To understand chemical deposition, it's helpful to contrast it with its counterpart, PVD. In PVD, a source material is physically ejected—by evaporation or ion bombardment (sputtering)—and travels through a vacuum to coat the substrate. No chemical reaction occurs; it is a direct transfer of the source material.

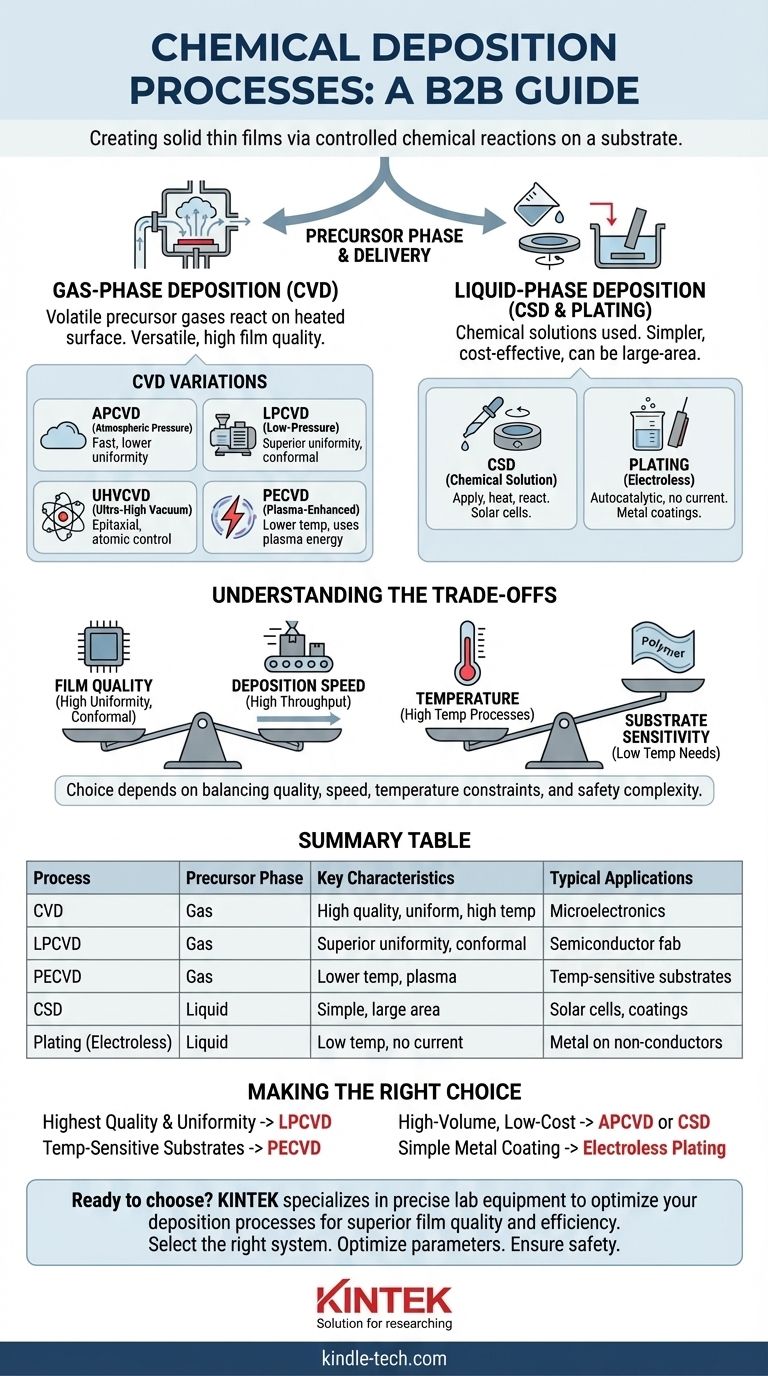

Major Categories of Chemical Deposition

The processes are best understood by grouping them based on whether the precursor is delivered as a gas or a liquid.

Gas-Phase Deposition: Chemical Vapor Deposition (CVD)

CVD is the most prominent and versatile category of chemical deposition. In this process, volatile precursor gases are introduced into a reaction chamber where they flow over a heated substrate. The heat provides the energy needed for the gases to react and/or decompose, leaving behind a solid film.

The properties of the final film are highly dependent on the CVD process conditions.

Liquid-Phase Deposition: CSD and Plating

These methods use a chemical solution instead of a gas.

Chemical Solution Deposition (CSD) involves applying a liquid precursor solution to a substrate (e.g., by spinning or dipping) and then heating it. The heat evaporates the solvent and initiates a chemical reaction to form the desired solid film.

Plating (specifically electroless plating) uses a chemical reducing agent within a solution to deposit a metallic film onto a substrate without an external electrical current. It is an autocatalytic chemical reaction in a liquid bath.

A Deeper Look into CVD Variations

Because CVD is so widely used, several specialized variations have been developed to control the deposition environment. The main variable is the pressure inside the reaction chamber.

The Role of Pressure

Pressure determines how gas molecules travel and interact.

- Atmospheric Pressure CVD (APCVD): Performed at normal atmospheric pressure. This process is fast and relatively inexpensive but can result in lower film uniformity compared to vacuum-based methods.

- Low-Pressure CVD (LPCVD): Performed at reduced pressure. This slows down the deposition but significantly improves the film's uniformity and its ability to conformally coat complex, three-dimensional structures.

- Ultra-High Vacuum CVD (UHVCVD): An extreme version of LPCVD used for creating highly pure, epitaxial films where atomic-level control is required.

The Role of Plasma: PECVD

Some substrates, like plastics or devices with existing circuitry, cannot tolerate the high temperatures required for traditional CVD.

Plasma-Enhanced CVD (PECVD) solves this problem. It uses an electric field to generate a plasma (an ionized gas), which provides the energy for the chemical reaction. This allows high-quality films to be deposited at much lower temperatures.

Understanding the Trade-offs

Choosing a chemical deposition process involves balancing competing factors. There is no single "best" method; the ideal choice depends entirely on the goal.

Film Quality vs. Deposition Speed

There is often a direct trade-off between quality and speed. High-pressure processes like APCVD are fast and suitable for high-throughput applications, but the film may be less uniform. Low-pressure processes like LPCVD are slow but produce superior, highly conformal films required for intricate microelectronics.

Temperature Constraints and Substrate Damage

High temperatures can be destructive. While thermal CVD creates excellent films, it cannot be used on temperature-sensitive materials. In these cases, a lower-temperature process like PECVD is necessary, though it introduces the complexity and cost of plasma generation systems.

Precursor Chemistry and Safety

CVD relies on volatile precursors, which are often highly toxic, flammable, or corrosive gases (e.g., silane, phosphine). Managing these materials requires significant investment in safety protocols, gas handling infrastructure, and exhaust treatment, adding complexity and cost to the operation.

Making the Right Choice for Your Goal

Your application's specific requirements will dictate the most appropriate deposition method.

- If your primary focus is the highest quality and uniformity on complex surfaces: LPCVD is the industry standard for microfabrication and advanced electronics.

- If your primary focus is depositing on temperature-sensitive substrates: PECVD is the essential choice for polymers, organic electronics, or post-processed wafers.

- If your primary focus is high-volume, low-cost coating on stable substrates: APCVD or CSD are excellent for large-area applications like solar cells or protective coatings on glass.

- If your primary focus is a simple, low-temperature metal coating: Electroless plating is a cost-effective method that does not require complex vacuum equipment.

Ultimately, selecting the right chemical deposition process requires a clear understanding of your material, substrate, and performance targets.

Summary Table:

| Process | Precursor Phase | Key Characteristics | Typical Applications |

|---|---|---|---|

| CVD (Chemical Vapor Deposition) | Gas | High film quality, uniform, high temperature | Microelectronics, advanced coatings |

| LPCVD (Low-Pressure CVD) | Gas | Superior uniformity, conformal coating | Semiconductor fabrication |

| PECVD (Plasma-Enhanced CVD) | Gas | Lower temperature, uses plasma | Temperature-sensitive substrates |

| CSD (Chemical Solution Deposition) | Liquid | Simple, cost-effective, large area | Solar cells, protective coatings |

| Plating (Electroless) | Liquid | Low temperature, no electrical current | Metal coatings on non-conductors |

Ready to choose the right deposition process for your application?

The selection between CVD, CSD, and plating is critical for achieving your desired film properties, whether you need high uniformity, low-temperature processing, or cost-effective large-area coating. At KINTEK, we specialize in providing the precise lab equipment and consumables needed for your deposition processes.

Our expertise can help you:

- Select the right system for your specific material and substrate requirements

- Optimize process parameters to achieve superior film quality and performance

- Ensure safety and efficiency with reliable equipment and consumables

Let our team guide you to the optimal solution. Contact KINTEK today to discuss your laboratory needs and discover how our specialized equipment can enhance your research and production outcomes.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is chemical Vapour deposition in simple words? A Simple Guide to 'Painting' with Gas

- What is CVD technique? A Guide to High-Performance Thin Film Manufacturing

- What is the chemical vapor deposition method for CNT? A Guide to Controlled, Scalable Nanotube Synthesis

- How do you deposit silicon carbide? Choosing the Right Method for Thin Films vs. Bulk Material

- What is the pressure range of LPCVD? Master the Key to Superior Film Conformality

- What effects the deposition rate? Master the Key Variables for Optimal Sputtering

- What are the advantages and disadvantages of chemical vapor deposition? A Guide to High-Performance Coating

- Why is a high-precision MFC essential for CVD systems? Ensure Superior Membrane Separation Performance