At its core, the primary defects of sintering are microstructural flaws that compromise the final part's integrity, such as residual porosity, uncontrolled grain growth, and dimensional inaccuracies like warping. These issues arise from a failure to precisely control the diffusion bonding process at the heart of sintering, where individual powder particles are fused into a solid mass.

While sintering is a powerful method for creating dense components from materials with high melting points, its fundamental challenge lies in managing the delicate balance of heat, time, and pressure. Deviations lead not only to material defects but also expose the process to significant financial and regulatory risks.

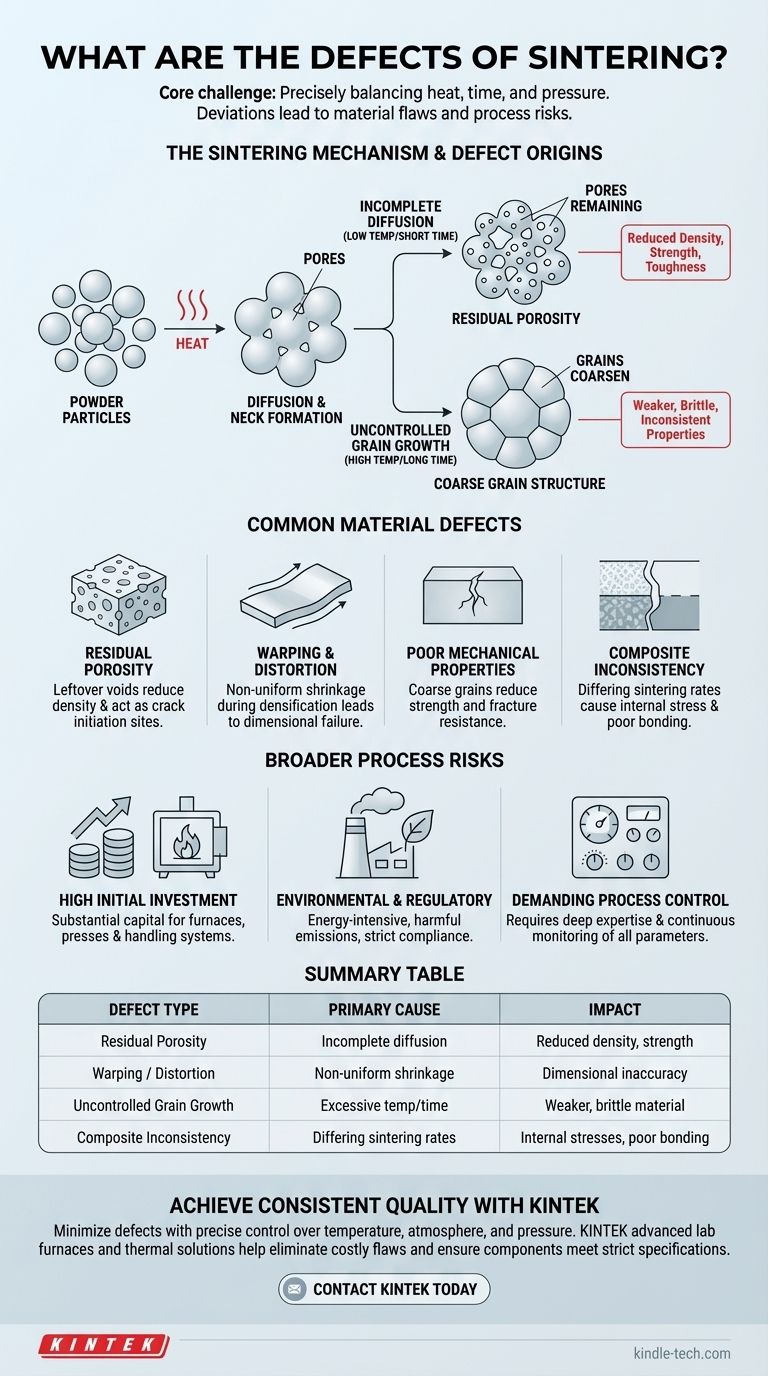

The Source of Defects: The Sintering Mechanism

To understand the defects, we must first understand the process. Sintering transforms a loosely packed "green body" of powder into a dense, solid object.

From Powder to Solid State

The process begins by heating the powdered material to a temperature below its melting point. At these high temperatures, atoms at the contact points between powder particles begin to diffuse, creating and enlarging "necks" that bond the particles together.

As this diffusion continues, the particle centers are pulled closer, systematically eliminating the empty spaces (pores) between them. This is what increases the part's density and strength.

Where Things Go Wrong: Incomplete Diffusion

Defects often originate when this diffusion process is incomplete or non-uniform. If the temperature is too low or the time is too short, the necks between particles won't fully form, and pores will remain trapped within the material.

The Problem of Uncontrolled Grain Growth

Conversely, if the temperature is too high or held for too long, the grains of the material can grow excessively large. While this may eliminate pores, it often leads to a weaker, more brittle final product with inconsistent mechanical properties.

Common Material Defects in Sintered Parts

The challenges in controlling the sintering mechanism manifest as specific, measurable defects in the final component.

Residual Porosity

This is the most common defect. Pores are leftover voids that were not eliminated during densification. High porosity reduces the material's density, strength, and toughness, and can act as initiation sites for cracks under stress.

Warping and Dimensional Inaccuracy

Sintering almost always involves shrinkage as the pores are eliminated. If this shrinkage is not perfectly uniform across the entire part—due to uneven heating or inconsistent powder packing—the component can warp, distort, or fail to meet critical dimensional tolerances.

Poor Mechanical Properties

Even in a fully dense part, defects can exist at the microstructural level. Uncontrolled grain growth leads to a coarse grain structure, which typically reduces material strength and fracture resistance compared to a fine-grained equivalent.

Complexity with Composite Materials

When sintering multiple materials together (composites), the process becomes significantly more complex. Different materials have different sintering temperatures and diffusion rates, making it difficult to achieve a uniform, well-bonded structure without introducing internal stresses or unwanted chemical reactions.

Understanding the Broader Process Risks

Beyond material defects, sintering carries significant operational and financial risks that must be considered.

High Initial Investment

The equipment required for sintering—high-temperature furnaces, high-pressure presses, and powder handling systems—represents a substantial capital investment. For low-volume products, this high barrier to entry can make the process economically unviable.

Environmental and Regulatory Hurdles

Sintering is an energy-intensive process. Furthermore, the initial heating phase often involves burning off organic binders used to shape the green body, which can release harmful emissions. This subjects operations to strict environmental regulations that can impact production rates and increase compliance costs.

Demanding Process Control

Sintering is not a simple "set it and forget it" process. Achieving consistent, high-quality results requires deep expertise and tight, continuous control over key parameters like temperature profiles, pressure, atmosphere, and the initial powder characteristics (particle size and shape).

Making the Right Choice for Your Goal

Evaluating sintering requires weighing its unique capabilities against its inherent challenges. Your primary objective should guide your decision.

- If your primary focus is achieving maximum density and strength: You must invest in precise process control to minimize porosity and manage grain size, as these are the biggest threats to mechanical integrity.

- If your primary focus is producing complex, near-net-shape parts: Your main challenge will be managing non-uniform shrinkage, requiring careful tooling design and potentially process modeling to avoid warping.

- If your primary focus is cost-sensitive or low-volume production: You must seriously evaluate the high capital cost of sintering equipment against alternative manufacturing methods.

Understanding these potential defects and process risks is the critical first step toward successfully leveraging the unique capabilities of sintering.

Summary Table:

| Defect Type | Primary Cause | Impact on Final Part |

|---|---|---|

| Residual Porosity | Incomplete diffusion (low temp/short time) | Reduced density, strength, and toughness |

| Warping / Distortion | Non-uniform shrinkage during densification | Dimensional inaccuracy, failure to meet tolerances |

| Uncontrolled Grain Growth | Excessive temperature or time | Weaker, more brittle material with inconsistent properties |

| Composite Inconsistency | Differing sintering rates of materials | Internal stresses, poor bonding, chemical reactions |

Achieve consistent, high-quality sintered parts with KINTEK.

Minimizing defects like porosity and warping requires precise control over temperature, atmosphere, and pressure. KINTEK specializes in advanced lab furnaces and thermal processing solutions designed for the demanding requirements of sintering. Our equipment helps you eliminate costly flaws, improve material properties, and ensure your components meet strict specifications.

Let our experts help you optimize your sintering process. Contact KINTEK today to discuss your laboratory's specific needs.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- How does an industrial vacuum drying oven contribute to the post-processing of gradient cathode material precursors?

- What is the difference between vertical and horizontal furnace semiconductors? Unlock Superior Yield and Uniformity

- How does a high-temperature sintering furnace transform c-LLZO green bodies into dense ceramic electrolytes? Expert Guide

- What furnace is used for heat treatment? Match Your Process to the Perfect Equipment

- What are the hazards of quenching? Avoid Material Failure and Personnel Injury

- Why is a high-vacuum high-temperature furnace necessary for Zr-4 alloy annealing? Ensure Superior Coating Adhesion

- What is the difference between plasma nitriding and nitrocarburizing? Choosing the Right Surface Hardening Process

- Does radiation happen through vacuum? Yes, It's the Only Heat Transfer Method That Can