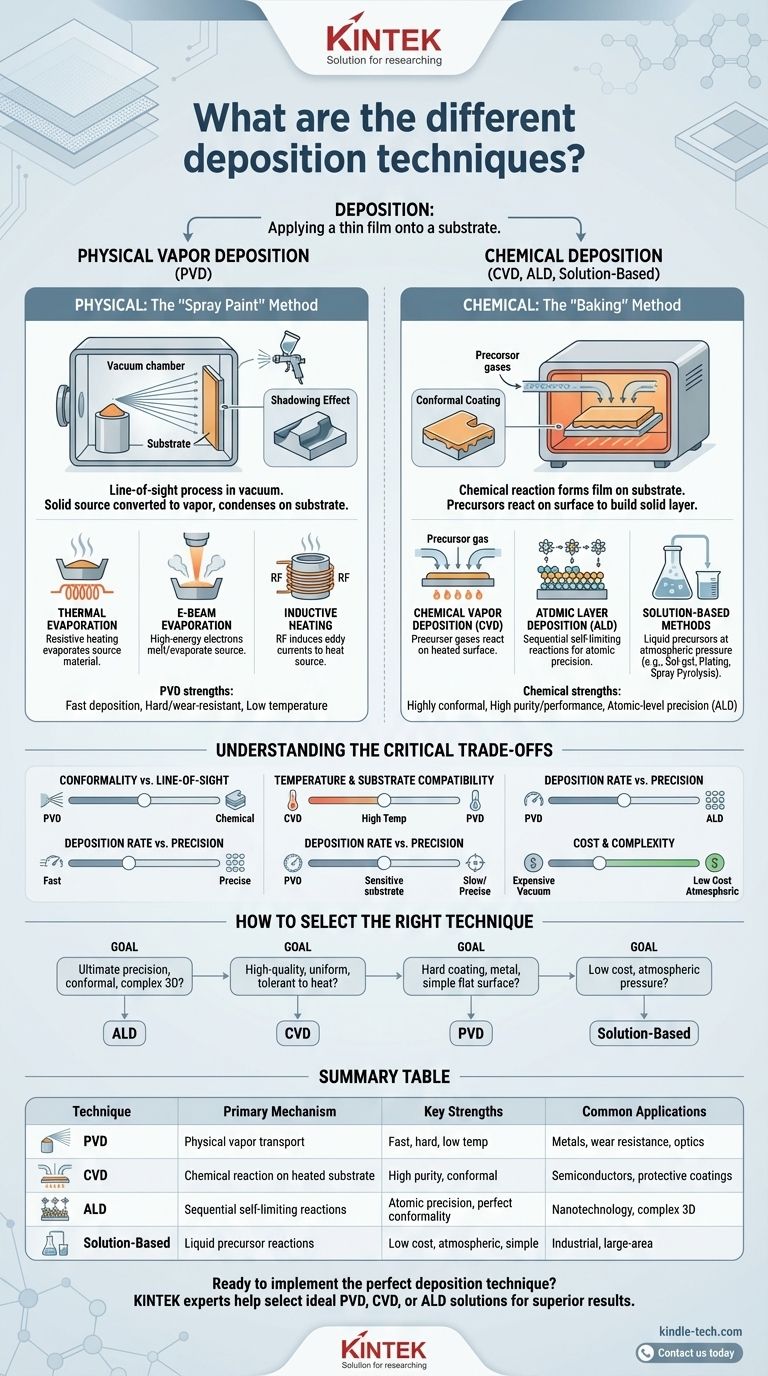

At its core, a deposition technique is any process used to apply a thin film of material onto a surface, known as a substrate. The major categories of these techniques are Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), Atomic Layer Deposition (ALD), and a range of solution-based chemical methods like plating, sol-gel, and spray pyrolysis.

The crucial difference between deposition techniques lies in how they deliver material to the substrate. Some methods physically transport solid material through a vacuum, while others use chemical reactions that occur directly on the substrate's surface. This distinction dictates the film's quality, uniformity, and suitability for a given application.

The Foundational Divide: Physical vs. Chemical

All deposition techniques follow three fundamental steps: creating the material species to be deposited, transporting them to the substrate, and ensuring they adhere to form a film. The two main families of techniques accomplish this in vastly different ways.

Physical Deposition: The "Spray Paint" Method

Physical Vapor Deposition (PVD) is a "line-of-sight" process that occurs in a vacuum. A solid source material is converted into a vapor, which then travels in a straight line and condenses on the substrate.

Think of this like using a can of spray paint. The paint particles travel directly from the nozzle to the surface, but they cannot easily coat the underside or hidden corners of an object.

Chemical Deposition: The "Baking" Method

Chemical deposition methods use a chemical reaction to form the film. Precursor materials, often in a gas or liquid state, are introduced to the substrate, where they react and form a new, solid material layer.

This is more like baking a cake. You mix liquid ingredients (precursors), and heat causes them to react and form a solid cake (the film) that perfectly conforms to the shape of the pan (the substrate).

Exploring Physical Vapor Deposition (PVD)

PVD is a family of vacuum-based techniques ideal for creating hard, wear-resistant, or metallic coatings.

Thermal Evaporation

This is one of the simplest PVD methods. A resistive heat source, like a super-heated wire, is used to heat the source material in a vacuum until it evaporates and coats the substrate.

Electron-Beam (E-Beam) Evaporation

For materials with very high melting points, a focused beam of high-energy electrons is used to melt and evaporate the source material. This allows for the deposition of durable metals and ceramics.

Inductive Heating

In this technique, radio frequency (RF) power is passed through a coil wrapped around a crucible containing the source material. This induces eddy currents that heat the material to its evaporation point, offering a path to very high-purity films.

Exploring Chemical Deposition Methods

Chemical methods are defined by their ability to produce highly conformal coatings that uniformly cover even the most complex 3D shapes.

Chemical Vapor Deposition (CVD)

CVD involves flowing precursor gases over a heated substrate. The heat triggers a chemical reaction on the surface, depositing a high-purity, high-performance film. It is a workhorse for the semiconductor and materials science industries.

Atomic Layer Deposition (ALD)

ALD is a powerful subtype of CVD that builds a film one single atomic layer at a time. It uses a sequence of self-limiting chemical reactions, providing unparalleled precision, thickness control, and perfect conformality.

Solution-Based and Plating Methods

Techniques like sol-gel, chemical bath deposition, spray pyrolysis, and plating (both electro- and electroless) do not require a vacuum. They rely on liquid precursors and are often simpler and less expensive, making them suitable for a wide range of industrial applications where cost is a primary driver.

Understanding the Critical Trade-offs

No single technique is universally superior. The choice always involves a set of engineering trade-offs.

Conformality vs. Line-of-Sight

Chemical methods (CVD, ALD) excel at coating complex shapes uniformly. PVD is a line-of-sight process and suffers from a "shadowing" effect, making it difficult to coat non-flat surfaces evenly.

Temperature and Substrate Compatibility

CVD often requires very high temperatures to drive the surface reactions, which can damage sensitive substrates like plastics or certain electronic components. Many PVD processes can operate at lower temperatures.

Deposition Rate vs. Precision

PVD techniques can deposit material very quickly, making them efficient for thick coatings. At the other extreme, ALD is exceptionally slow due to its layer-by-layer nature but offers unmatched control.

Cost and Complexity

Vacuum systems for PVD, CVD, and ALD are expensive to purchase and operate. Solution-based methods that work at atmospheric pressure are generally far more cost-effective.

How to Select the Right Technique

Choosing a deposition method requires aligning the technique's strengths with your primary project goal.

- If your primary focus is ultimate precision and conformality on complex 3D structures: ALD is the definitive choice, despite its slow speed.

- If you need a high-quality, uniform coating on many parts and the substrate can tolerate heat: CVD offers a strong balance of quality and throughput.

- If you are depositing a hard coating, metal, or simple ceramic onto a relatively flat surface: PVD techniques are a highly effective and mature choice.

- If your priority is low cost and you are working at atmospheric pressure: Solution-based methods like plating or spray pyrolysis are the most practical options.

Understanding these core principles moves you from simply listing techniques to strategically selecting the right tool for your engineering goal.

Summary Table:

| Technique | Primary Mechanism | Key Strengths | Common Applications |

|---|---|---|---|

| PVD | Physical vapor transport in vacuum | Fast deposition, hard coatings, low temperature | Metal coatings, wear resistance, optics |

| CVD | Chemical reaction on heated substrate | High purity, good conformality, high performance | Semiconductors, protective coatings |

| ALD | Sequential self-limiting reactions | Atomic-level precision, perfect conformality | Nanotechnology, complex 3D structures |

| Solution-Based | Liquid precursor reactions | Low cost, atmospheric pressure, simplicity | Industrial coatings, large-area applications |

Ready to implement the perfect deposition technique for your project? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision deposition systems. Our experts can help you select the ideal PVD, CVD, or ALD solution to achieve superior thin-film results. Contact us today to discuss your specific application requirements and discover how our equipment can enhance your research or production process.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings