In engineering and metallurgy, annealing refers to a family of heat treatment processes, not a single one. The primary types include Full Annealing, Process Annealing, Stress Relief Annealing, and Spheroidizing, each designed to modify a metal's microstructure to achieve a specific outcome, such as softening the material, improving its formability, or increasing its machinability. These processes are distinct from the internal stages a metal undergoes during heating.

The core principle of annealing is using controlled heating and cooling to manipulate a metal's internal crystal structure. The specific "type" of annealing you choose is simply a recipe of temperature, time, and cooling rate tailored to achieve a precise set of final mechanical properties.

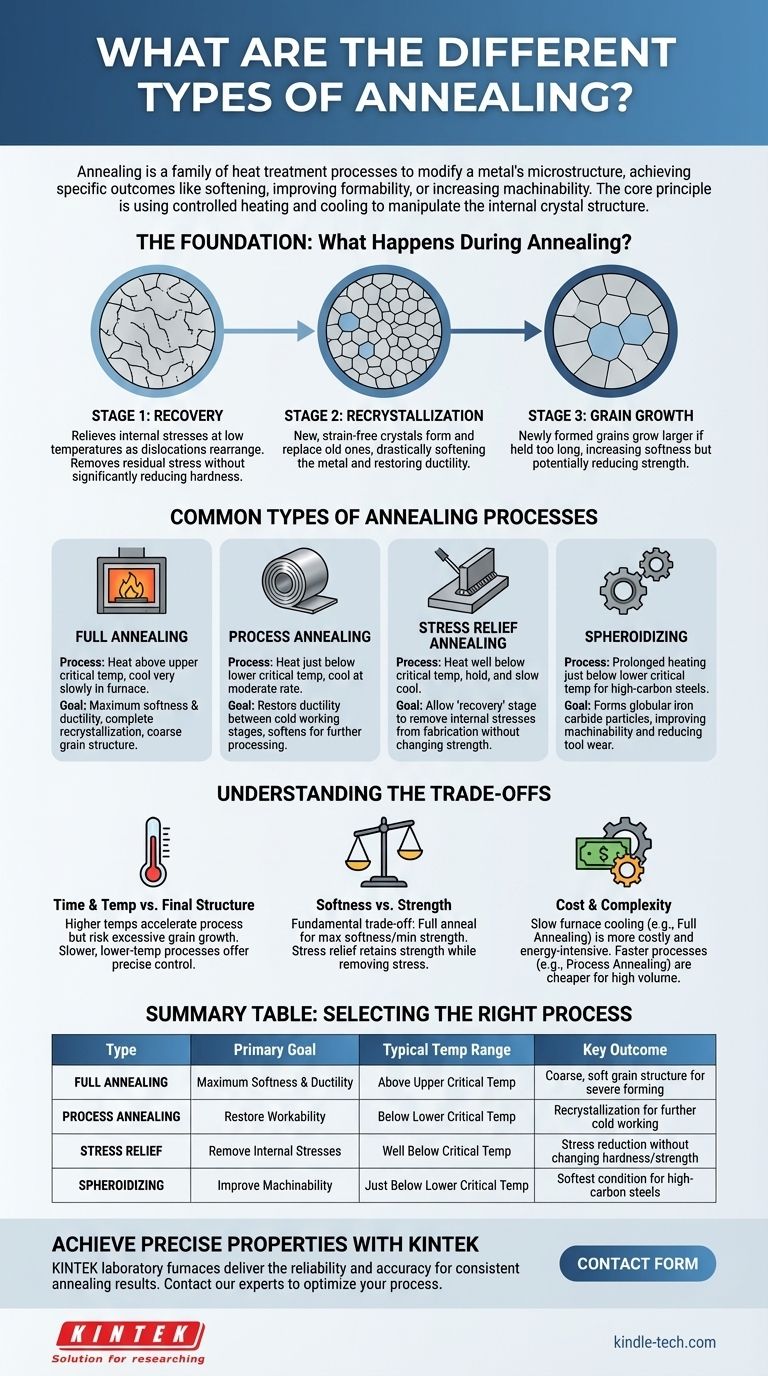

The Foundation: What Happens During Annealing?

Before examining the different industrial processes, it's crucial to understand the three universal microstructural stages that occur as a metal is heated. These stages—Recovery, Recrystallization, and Grain Growth—are the fundamental mechanisms behind any annealing process.

Stage 1: Recovery

At relatively low temperatures, the metal begins to relieve internal stresses. This stage, known as recovery, happens as dislocations (defects in the crystal structure) within the metal move and arrange themselves into lower-energy patterns. It removes residual stress without significantly reducing the material's hardness or strength.

Stage 2: Recrystallization

As the temperature increases to a specific point (the recrystallization temperature), a dramatic change occurs. New, strain-free crystals, or "grains," begin to form and replace the old, deformed ones created during cold working. This stage is the heart of most annealing processes, as it drastically softens the metal and restores its ductility.

Stage 3: Grain Growth

If the metal is held at or above the recrystallization temperature for too long, the newly formed, strain-free grains will begin to merge and grow larger. While this can further increase softness, excessive grain growth is often undesirable as it can reduce the material's strength and toughness. Controlling this stage is key to achieving consistent results.

Common Types of Annealing Processes

Each type of annealing is a practical application of the stages above, designed to achieve a specific engineering goal.

Full Annealing

This process involves heating steel to above its upper critical temperature (where the crystal structure fully transforms) and then cooling it very slowly, typically by leaving it in the furnace to cool.

The goal of full annealing is to produce a metal in its softest, most ductile state. It ensures complete recrystallization and promotes a coarse grain structure, making the material easy to form or machine.

Process Annealing

Also known as subcritical annealing, this process involves heating a metal to a temperature just below its lower critical temperature. The material is held at this temperature long enough for recrystallization to occur and is then cooled at a moderate rate.

Process annealing is used to restore ductility to a workpiece between different stages of cold working (e.g., wire drawing or sheet rolling). It softens the metal enough for further processing without the time and energy cost of a full anneal.

Stress Relief Annealing

This is a low-temperature process where the metal is heated well below its critical temperature, held for a specific time, and then slowly cooled.

The sole purpose of stress relief is to allow the "recovery" stage to occur, removing internal stresses introduced by welding, casting, or heavy machining. It does so without significantly changing the material's strength or hardness, making it ideal for finished or semi-finished components.

Spheroidizing

This specialized process is used primarily for high-carbon steels to improve machinability. It involves prolonged heating at a temperature just below the lower critical temperature, causing the hard iron carbide (cementite) phase to form small, globular particles within the softer ferrite matrix.

A spheroidized structure is the softest possible condition for high-carbon steel, which dramatically reduces tool wear during cutting operations.

Understanding the Trade-offs

Choosing an annealing process requires balancing competing factors. There is no single "best" method; the optimal choice depends entirely on the goal.

Time and Temperature vs. Final Structure

Higher temperatures accelerate the annealing process but increase the risk of excessive grain growth, which can harm the final properties. Slower, lower-temperature processes like spheroidizing offer precise structural control but are significantly more time-consuming.

Softness vs. Strength

The fundamental trade-off in annealing is between softness (ductility) and strength (hardness). A full anneal produces maximum softness but minimum strength. A stress relief anneal, by contrast, retains nearly all of the material's strength while only relieving internal stress.

Cost and Complexity

Processes requiring very slow furnace cooling, like full annealing, occupy equipment for long periods and consume significant energy. Faster processes like process annealing, which may allow for air cooling, are generally cheaper and better suited for high-volume production environments.

Selecting the Right Annealing Process

Your choice should be driven by the material you are working with and your end goal.

- If your primary focus is maximum softness and ductility for severe forming: Use full annealing to create the most malleable structure possible.

- If your primary focus is restoring workability between cold working operations: Use process annealing as a cost-effective way to regain ductility for subsequent steps.

- If your primary focus is removing internal stresses without losing strength: Use stress relief annealing to stabilize the component after fabrication.

- If your primary focus is improving the machinability of high-carbon steel: Use spheroidizing to produce the ideal microstructure for cutting operations.

By matching the specific annealing process to your material and your desired outcome, you gain precise control over its final performance.

Summary Table:

| Type of Annealing | Primary Goal | Typical Temperature Range | Key Outcome |

|---|---|---|---|

| Full Annealing | Maximum Softness & Ductility | Above Upper Critical Temperature | Coarse, soft grain structure for severe forming |

| Process Annealing | Restore Workability | Below Lower Critical Temperature | Recrystallization for further cold working |

| Stress Relief | Remove Internal Stresses | Well Below Critical Temperature | Stress reduction without changing hardness/strength |

| Spheroidizing | Improve Machinability | Just Below Lower Critical Temperature | Softest condition for high-carbon steels |

Achieve Precise Material Properties with KINTEK Laboratory Furnaces

Selecting the right annealing process is critical, but achieving consistent, repeatable results requires precise temperature control. Whether you are conducting full annealing for maximum ductility or spheroidizing to improve machinability, KINTEK's advanced laboratory furnaces are engineered to deliver the reliability and accuracy your research or production demands.

KINTEK specializes in lab equipment and consumables, serving the precise heat treatment needs of metallurgy, materials science, and R&D laboratories. Our furnaces provide the uniform heating and controlled cooling environments essential for successful annealing.

Ready to optimize your annealing processes? Contact our experts today via our Contact Form to discuss how our solutions can enhance your workflow and material performance.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing