At its core, heat treatment for steel involves a controlled sequence of heating and cooling operations to intentionally alter the metal's internal microstructure. The primary processes are annealing, normalizing, hardening (which involves quenching and tempering), and case hardening. Each process is designed to achieve a specific set of mechanical properties, such as softness, hardness, toughness, or wear resistance.

The key to understanding heat treatment is to see it not as a list of separate recipes, but as a toolkit for manipulating a single trade-off: the balance between hardness and toughness. By controlling the heating and cooling rates, you are precisely controlling the steel's internal structure to meet a specific engineering demand.

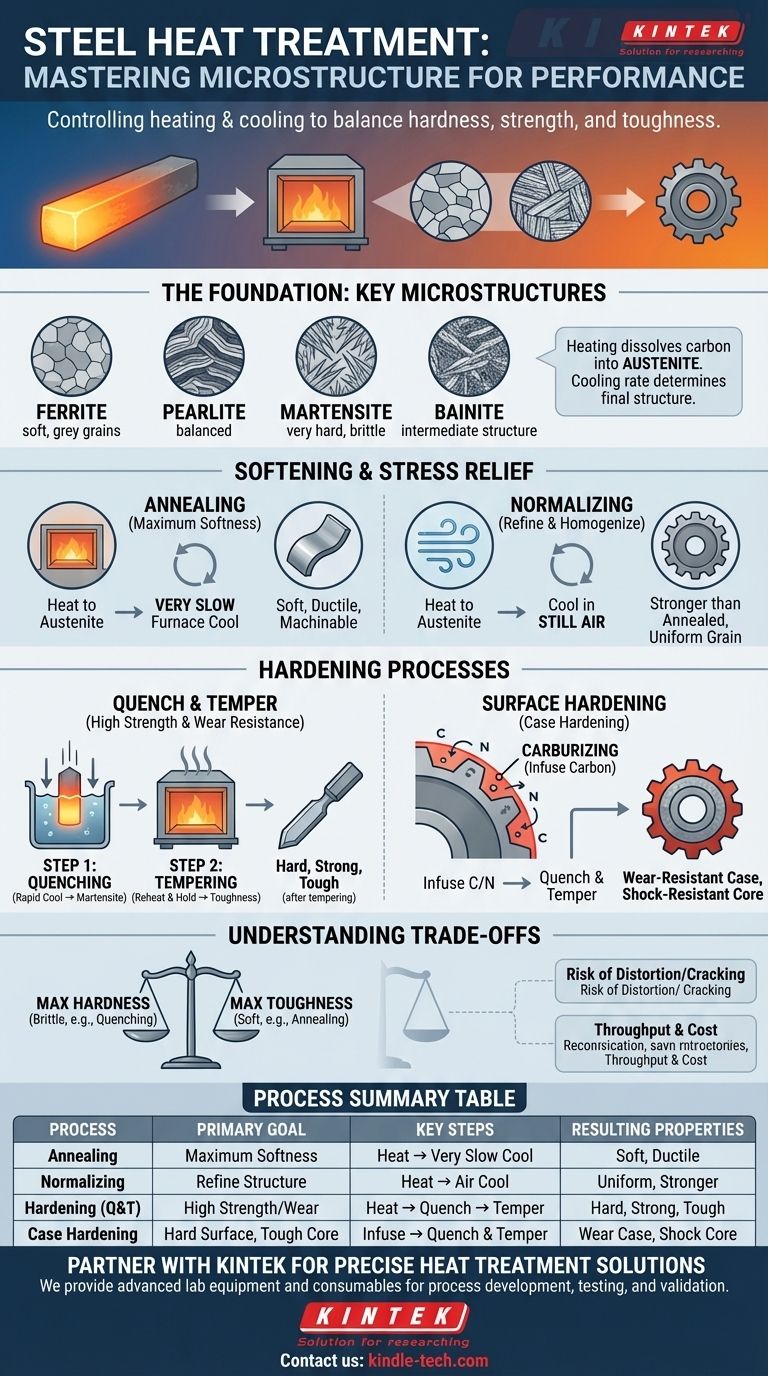

The Foundation: Why Heat Treat Steel?

The properties of steel are determined by its microscopic crystalline structure, or microstructure. Heat treatment works by transforming this structure from one form to another.

The Role of Temperature and Carbon

Heating steel above a critical temperature (the austenitizing temperature) dissolves carbon into a uniform structure called austenite.

How you cool the steel from this austenitic state determines the final microstructure and, therefore, its mechanical properties.

The Key Microstructures

- Ferrite: A soft, ductile structure formed by very slow cooling.

- Pearlite: A mix of ferrite and hard iron carbide, formed by moderate cooling. It offers a balance of strength and ductility.

- Martensite: A very hard, brittle, needle-like structure formed by rapid cooling (quenching). This is the basis for most hardening operations.

- Bainite: A structure with properties between pearlite and martensite, formed by specific cooling rates.

Softening and Stress Relief Processes

These processes are typically used to make steel easier to machine, form, or to remove internal stresses built up during manufacturing.

Annealing: For Maximum Softness

Annealing involves heating steel into the austenite region and then cooling it extremely slowly, often by leaving it inside the furnace as it cools.

This slow cooling process produces a coarse pearlite and ferrite microstructure, resulting in the softest, most ductile, and most easily machinable state for the steel.

Normalizing: To Refine and Homogenize

Normalizing also involves heating to the austenitic range, but the steel is then cooled in still air.

This faster cooling rate produces a finer, more uniform grain structure than annealing. The result is a steel that is slightly harder and stronger than an annealed steel but less brittle than a hardened one. It is often used to improve the consistency of as-forged or as-rolled parts.

Hardening Processes

Hardening is a two-step process used to create a combination of high strength, wear resistance, and adequate toughness.

Step 1: Quenching for Maximum Hardness

First, the steel is heated to form austenite and then cooled rapidly by plunging it into a quenching medium like water, oil, or forced air.

This rapid cooling, or quenching, prevents the formation of softer structures and instead transforms the austenite into martensite, the hardest possible microstructure. In this as-quenched state, the steel is extremely hard but also very brittle and unsuitable for most applications.

Step 2: Tempering for Toughness

After quenching, the brittle part must be reheated to a lower temperature (below the austenitizing temperature) and held for a specific time. This process is called tempering.

Tempering relieves the internal stresses from quenching and allows some of the martensite to transform, reducing hardness but significantly increasing toughness. The higher the tempering temperature, the softer and tougher the steel becomes.

Surface Hardening (Case Hardening)

Case hardening creates a part with a hard, wear-resistant outer shell (the "case") and a softer, tougher inner core. This is ideal for components like gears and bearings that need to resist surface wear while also withstanding impact loads.

Carburizing

Carburizing is the most common method. It involves heating a low-carbon steel in a carbon-rich atmosphere. Carbon diffuses into the surface of the part.

After the carbon is infused, the part is quenched and tempered. This hardens the high-carbon case into martensite while the low-carbon core remains softer and tougher.

Other Surface Methods

Other methods like Nitriding (infusing nitrogen) or Induction Hardening (using electromagnetic fields to rapidly heat only the surface) can achieve similar results without changing the chemical composition of the surface layer.

Understanding the Trade-offs

Heat treatment is not a magic bullet; every process involves balancing competing properties and risks.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off. Processes that maximize hardness (like quenching) inherently create a brittle material. Processes that increase toughness (like tempering and annealing) do so at the expense of hardness and strength.

Risk of Distortion and Cracking

The rapid temperature changes and structural transformations involved in quenching introduce massive internal stresses. If not managed carefully, these stresses can cause the part to warp, distort, or even crack during the process.

Throughput and Cost

Processes with very long cooling cycles, like full annealing, can take many hours and consume significant energy, adding to the final cost of the component. Quenching and tempering is a much faster, but more complex, operation.

Selecting the Right Process for Your Goal

Your choice of heat treatment must be directly linked to the final application of the steel component.

- If your primary focus is maximum machinability or formability: Choose annealing to put the steel in its softest possible state.

- If your primary focus is high strength and wear resistance: Use hardening (quench and temper) to create a strong, tough martensitic structure.

- If your primary focus is a wear-resistant surface with a shock-resistant core: Use a case hardening process like carburizing.

- If your primary focus is improving the structural uniformity of a raw part: Use normalizing as a preparatory or final step.

Ultimately, heat treatment empowers you to precisely tailor the properties of steel to meet the demands of almost any engineering challenge.

Summary Table:

| Process | Primary Goal | Key Steps | Resulting Properties |

|---|---|---|---|

| Annealing | Maximum Softness / Stress Relief | Heat to austenite, then very slow furnace cool | Soft, ductile, easy to machine |

| Normalizing | Refine & Homogenize Grain Structure | Heat to austenite, then cool in still air | Stronger & harder than annealed, uniform structure |

| Hardening (Quench & Temper) | High Strength & Wear Resistance | Heat to austenite, quench (rapid cool), then temper | Hard, strong, and tough (after tempering) |

| Case Hardening | Hard Surface, Tough Core | Infuse carbon/nitrogen into surface, then quench & temper | Wear-resistant case, shock-resistant core |

Ready to Specify the Perfect Heat Treatment for Your Steel Components?

Choosing the right heat treatment process is critical to achieving the precise balance of hardness, strength, and toughness your application demands. The experts at KINTEK are here to help you navigate these critical decisions.

We provide the advanced lab equipment and consumables you need to develop, test, and validate your heat treatment processes, ensuring consistent, high-quality results.

Contact our team today to discuss how our solutions can support your laboratory's specific needs in metallurgy and materials testing.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How do high-temperature furnaces facilitate the pre-treatment of minerals? Optimize Solid-Solid Reactions

- How do high-precision programmable temperature-controlled furnaces contribute to the evaluation of catalytic performance?

- What is furnace sintering? A Guide to High-Temperature Powder Bonding for Stronger Parts

- What role does a high-temperature constant temperature oven play in PDMS membrane preparation? Curing for Durability

- What is powder sintering process? A Guide to Solid-State Metal & Ceramic Fabrication

- Can a muffle furnace be used for calcination? Achieve Pure, Controlled Thermal Decomposition

- What function does a muffle furnace serve in catalyst activation? Unlock Optimal Zr-Mo Performance

- What role does a muffle furnace play in Li2SiOx coating for NMC811? Optimize Cathode Stability & Performance