At its core, a pelletizer is classified by its die design. The two primary types of pellet machines are the flat die pelletizer and the ring die pelletizer. The fundamental difference between them dictates their scale, efficiency, and ideal application.

The choice between a pelletizer is not about which is universally "better," but which is the correct tool for your operational scale. Flat die machines are suited for smaller-scale production, while ring die machines are built for high-volume, industrial applications.

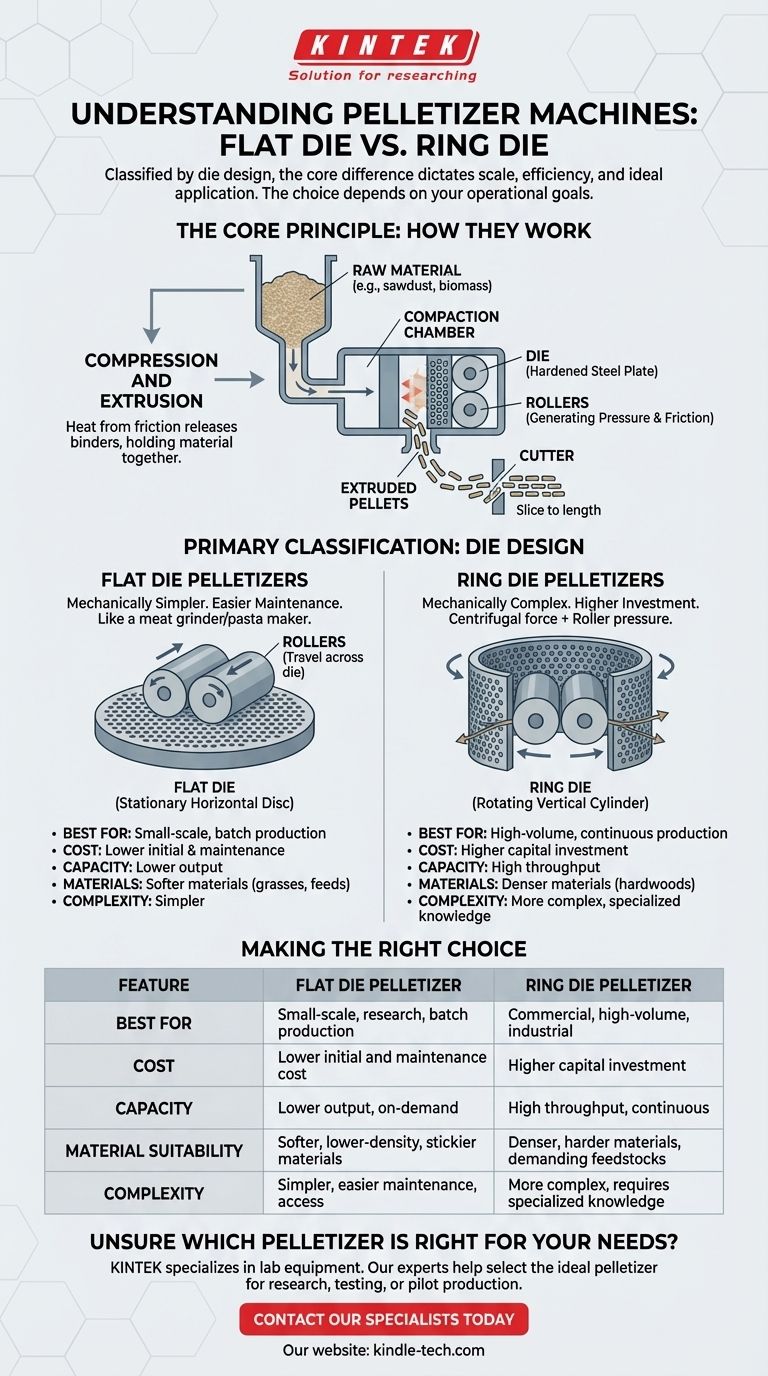

How Pelletizers Work: The Core Principle

The Mechanism of Compaction

All pelletizers operate on a simple, powerful principle: compression and extrusion. Raw, conditioned material (like sawdust, biomass, or animal feed) is fed into a chamber where it is forced through the holes of a hardened steel plate, known as a die.

Pressure and Heat Create the Pellet

This process generates immense pressure and friction. The heat created by this friction helps to release natural lignins in wood or activate binders in feed, which act as a glue to hold the compressed material together as it exits the die. A cutter then slices the extruded material into pellets of a desired length.

The Primary Classification: Die Design

The orientation and movement of the die and rollers are the most significant differentiators in pelletizer technology.

Flat Die Pelletizers

In a flat die machine, the die is a horizontal, perforated disc. Rollers travel across the top surface of this stationary disc, pressing the raw material down through the holes.

This design is mechanically simpler and generally easier to maintain. It is often compared to a meat grinder or a pasta maker in its basic concept of forcing material through a fixed plate.

Ring Die Pelletizers

In a ring die machine, the die is a vertical, perforated cylinder or "ring" that rotates at high speed. Rollers are positioned on the inside of the ring, remaining stationary as the die spins around them.

Centrifugal force flings the raw material against the inner surface of the rotating die. The rollers then press the material outward through the die holes, forming pellets on the exterior circumference.

A Second Classification: Drive System & Scale

While die design is the main distinction, machines can also be categorized by their power source and operational complexity.

Drive Mechanism

The power source is determined by the machine's size and intended location. Common types include electric motors for stationary industrial use, diesel engines for portable or off-grid applications, and even Power Take-Off (PTO) systems that connect to a tractor.

Operational Scale

This refers to the machine's output capacity and level of automation. It ranges from small, manual-feed press machines with a specific load capacity (measured in kilonewtons, or kN) to fully automated systems integrated into a larger production line. Typically, flat die designs are found in smaller-scale machines, while ring die designs dominate large, automated systems.

Understanding the Trade-offs: Flat Die vs. Ring Die

Choosing the right machine requires understanding its inherent advantages and limitations.

Cost and Complexity

Flat die machines are significantly less expensive to purchase and maintain. Their simpler construction means fewer complex parts and easier access for die and roller changes.

Ring die machines represent a major capital investment. They are more complex mechanically, requiring more specialized knowledge for operation and maintenance.

Production Capacity and Efficiency

Ring die pelletizers are the clear choice for high-volume, continuous production. Their design is inherently more efficient for large-scale operations, offering higher throughput and consistency.

Flat die pelletizers are best suited for smaller batches or on-demand production. Their output is considerably lower, making them impractical for commercial industrial plants.

Material Suitability

Flat die machines can be more forgiving with softer, lower-density, or stickier materials like grasses and some animal feeds, as the downward force is direct.

Ring die machines excel with denser, harder-to-pelletize materials like hardwoods. The high speed and intense pressure ensure consistent compaction for demanding industrial feedstocks.

Durability and Wear

The die on a ring die machine typically has a longer service life, as it wears more evenly and can often be used on both its inner and outer edges.

Flat die plates tend to wear more quickly due to the direct, downward pressure of the rollers. However, they are also much cheaper and easier to replace.

Making the Right Choice for Your Application

Your final decision should be guided by your production goals, raw materials, and budget.

- If your primary focus is small-scale production or research: A flat die pelletizer offers the most cost-effective and manageable solution for creating pellets for a small farm, personal home heating, or lab testing.

- If your primary focus is commercial, high-volume production: A ring die pelletizer is the necessary investment for an industrial operation like a large feed mill or a commercial wood pellet plant.

Ultimately, understanding this core distinction transforms the decision from a complex comparison of features to a clear choice based on your operational scale.

Summary Table:

| Feature | Flat Die Pelletizer | Ring Die Pelletizer |

|---|---|---|

| Best For | Small-scale, batch production | High-volume, continuous production |

| Cost | Lower initial and maintenance cost | Higher capital investment |

| Capacity | Lower output | High throughput |

| Material Suitability | Softer materials (grasses, feeds) | Denser materials (hardwoods) |

| Complexity | Simpler, easier maintenance | More complex, specialized knowledge needed |

Still unsure which pelletizer is right for your lab or production needs?

KINTEK specializes in lab equipment and consumables, serving precise laboratory requirements. Our experts can help you select the ideal pelletizer machine—whether for small-scale research, material testing, or pilot plant production—ensuring you get the performance and efficiency your work demands.

Contact our specialists today for a personalized consultation!

Visual Guide

Related Products

- Twin Screw Extruder Plastic Granulation Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Mini Planetary Ball Mill Machine for Laboratory Milling

People Also Ask

- What does a tablet punching machine consist of? Core Components for Efficient Tablet Production

- What is the working principle of pelletizing machine? Transform Powders into Dense, Uniform Pellets

- What is the use of single punch tablet press? For Precise R&D and Small-Batch Tablet Production

- What size are pellet mill die sizes? Master the L/D Ratio for Perfect Pellets

- What are pill presses called? The Correct Term is Tablet Press for Pharmaceutical Manufacturing

- What is a tablet punching machine called? Choosing the Right Press for Your Production Scale

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production