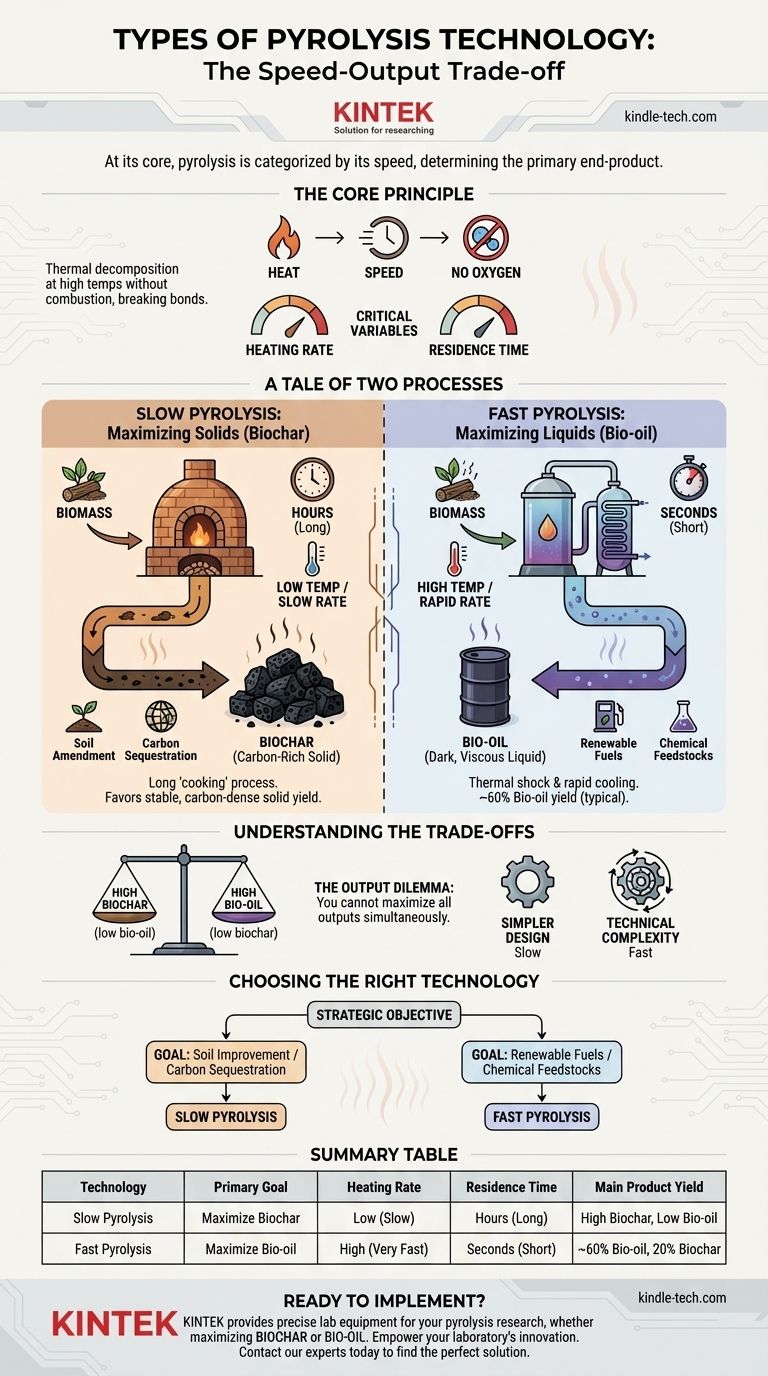

At its core, pyrolysis technology is categorized by its speed. The primary types are slow and fast pyrolysis, distinguished by the rate of heating and the duration of the process. Slow pyrolysis takes hours and is designed to maximize the solid output, biochar, while fast pyrolysis is completed in seconds and optimized to produce liquid bio-oil.

The choice between pyrolysis technologies is not about which is "better," but about defining your target end-product. The speed of the process is the fundamental lever that determines whether you will primarily yield a solid soil amender (biochar) or a liquid fuel source (bio-oil).

The Core Principle: Heat, Speed, and Oxygen

What is Pyrolysis?

Pyrolysis is a process of thermal decomposition. It uses high temperatures to break down materials, such as biomass or plastic, in a near-total absence of oxygen.

Preventing combustion is critical. Instead of burning, the material's chemical bonds break apart, reforming into a mix of solid, liquid, and gas products.

The Critical Variables

The outcome of pyrolysis is controlled by two main variables: heating rate (how fast the temperature rises) and residence time (how long the material is held at the target temperature).

Manipulating these two factors allows you to precisely steer the process toward your desired output.

A Tale of Two Processes: Slow vs. Fast Pyrolysis

Slow Pyrolysis: Maximizing Solids (Biochar)

Slow pyrolysis operates at relatively low temperatures with very slow heating rates. The entire process can take several hours to complete.

This long, slow "cooking" process systematically breaks down the feedstock, favoring the formation of a stable, carbon-rich solid known as biochar. The yield is primarily biochar, with smaller amounts of bio-oil and syngas produced as byproducts.

Think of it like making charcoal in a traditional kiln. The goal is to slowly transform the structure of the wood into a solid, carbon-dense product.

Fast Pyrolysis: Maximizing Liquids (Bio-oil)

Fast pyrolysis is the opposite. It uses high temperatures and an extremely rapid heating rate, completing the reaction in a matter of seconds.

This thermal shock rapidly vaporizes the biomass. The vapors are then quickly cooled and condensed into a dark, viscous liquid known as bio-oil, which can be used as a fuel or a source for renewable chemicals.

According to typical yields, fast pyrolysis converts feedstock into approximately 60% bio-oil, 20% biochar, and 20% syngas. This makes it the most widely used system for liquid fuel production goals.

Understanding the Trade-offs

The Output Dilemma

You cannot maximize all outputs simultaneously. Optimizing for high biochar yield through slow pyrolysis inherently reduces your bio-oil yield, and vice versa.

Your objective must be clear from the start, as it dictates the entire design and operation of the pyrolysis unit.

Technical Complexity

Fast pyrolysis systems are generally more complex. They require precise control over temperature, rapid heat transfer mechanisms, and often involve finely ground, dry feedstock to work effectively.

Slow pyrolysis reactors can be simpler in design and more tolerant of variations in feedstock moisture and size, making them potentially more robust for certain smaller-scale applications.

Choosing the Right Technology for Your Goal

Selecting the correct pyrolysis approach depends entirely on your strategic objective. There is no single best method; there is only the best method for your specific application.

- If your primary focus is soil improvement or carbon sequestration: Slow pyrolysis is the superior choice because it is designed to maximize the yield of stable, high-quality biochar.

- If your primary focus is producing renewable liquid fuels or chemical feedstocks: Fast pyrolysis is the necessary technology to maximize the yield of bio-oil.

Ultimately, understanding the relationship between process speed and final output empowers you to select the precise tool for your intended goal.

Summary Table:

| Technology | Primary Goal | Heating Rate | Residence Time | Main Product Yield |

|---|---|---|---|---|

| Slow Pyrolysis | Maximize Biochar | Low (Slow) | Hours (Long) | High Biochar, Low Bio-oil |

| Fast Pyrolysis | Maximize Bio-oil | High (Very Fast) | Seconds (Short) | ~60% Bio-oil, 20% Biochar |

Ready to Implement the Right Pyrolysis Technology for Your Lab?

Choosing between slow and fast pyrolysis is a critical decision that hinges on your target end-product. At KINTEK, we specialize in providing the precise lab equipment you need to conduct your pyrolysis research and development effectively.

Whether your goal is to maximize biochar for soil science and carbon sequestration studies or to produce bio-oil for renewable fuel and chemical feedstock research, we have the solutions to support your work.

Let KINTEK empower your laboratory's innovation. Our expertise in pyrolysis systems can help you achieve accurate, reliable results.

Contact our experts today to discuss your specific application and find the perfect equipment for your needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success