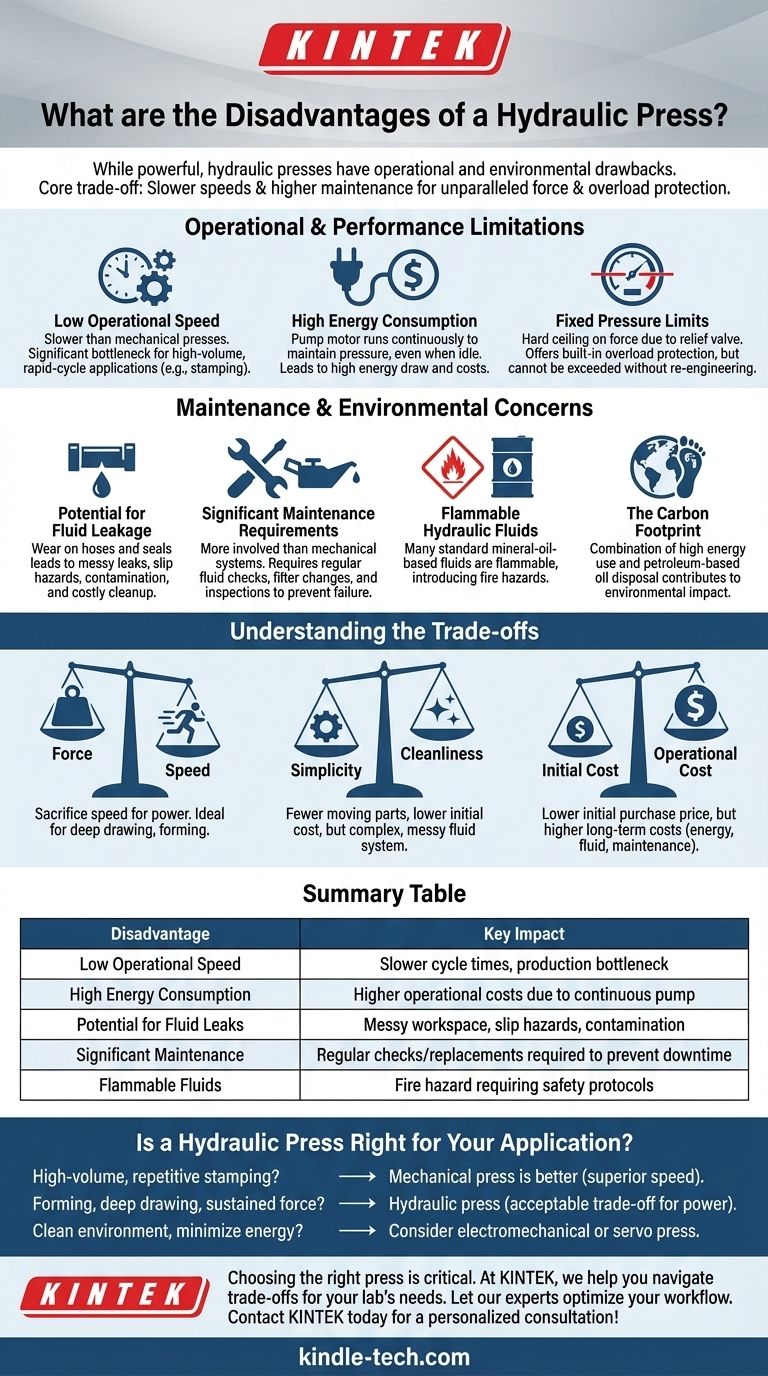

While incredibly powerful, hydraulic presses are not without their operational and environmental drawbacks. Their primary disadvantages stem from low operational speeds, the potential for messy fluid leaks, high energy consumption, and significant maintenance requirements compared to their mechanical counterparts.

The core trade-off of a hydraulic press is accepting slower speeds and higher maintenance in exchange for unparalleled force and overload protection. Understanding these limitations is key to determining if its power is right for your application.

Operational and Performance Limitations

While known for generating immense pressure, the method a hydraulic press uses to achieve this creates several performance constraints.

Low Operational Speed

A hydraulic press generates force by pumping fluid into a cylinder, which takes time. This process is inherently slower than the direct crank action of a mechanical press.

For high-volume, rapid-cycle applications like stamping, this lower speed can become a significant production bottleneck.

High Energy Consumption

The hydraulic pump motor often runs continuously to maintain system pressure, even when the press is idle between strokes.

This constant power draw can lead to high energy consumption and operational costs, especially when compared to mechanical presses that only draw peak power during the actual pressing motion.

Fixed Pressure Limits

Every hydraulic system is designed with a maximum pressure setting, regulated by a relief valve. While this provides excellent built-in overload protection (a key advantage), it also means there is a hard ceiling on the force you can apply.

You cannot exceed this designed limit without re-engineering the system.

Maintenance and Environmental Concerns

The reliance on hydraulic fluid introduces a unique set of challenges related to upkeep, safety, and environmental impact.

Potential for Fluid Leakage

Hydraulic systems rely on a network of hoses, fittings, and seals. Over time, these components can wear out, leading to fluid leaks.

Leaks are not only messy but also create workplace slip hazards, can contaminate parts, and require costly cleanup and fluid replacement.

Significant Maintenance Requirements

Maintaining a hydraulic system is more involved than a simple mechanical one. It requires regular checks of fluid levels, filter changes, and inspections of all seals and hoses to prevent failure.

Neglecting this routine maintenance can lead to unexpected downtime and expensive repairs.

Flammable Hydraulic Fluids

Many standard hydraulic fluids are mineral-oil-based and therefore flammable. This introduces a fire hazard into the workspace that must be managed with proper safety protocols and equipment.

While fire-resistant fluids are available, they are often more expensive and may have different performance characteristics.

The Carbon Footprint

The combination of high energy consumption and the use of petroleum-based oils gives hydraulic presses a notable environmental footprint. The oils require proper, regulated disposal at the end of their service life.

Understanding the Trade-offs

The disadvantages of a hydraulic press do not exist in a vacuum. They are direct trade-offs for its primary benefits.

Force vs. Speed

You sacrifice speed for power. A hydraulic press can deliver its maximum force at any point in the stroke, making it ideal for deep drawing, forming, and assembly applications where sustained pressure is critical. Mechanical presses only deliver maximum force at the very bottom of their stroke.

Simplicity vs. Cleanliness

The design of a hydraulic press is simple, with fewer moving parts than a mechanical press. This often leads to a lower initial cost and greater durability. However, this mechanical simplicity is traded for the complexity and potential messiness of a fluid-based system.

Initial Cost vs. Operational Cost

For high-tonnage applications, a hydraulic press often has a lower initial purchase price. However, the long-term operational costs related to energy consumption, fluid replacement, and routine maintenance can be higher.

Is a Hydraulic Press Right for Your Application?

By evaluating your primary goal, you can determine if these disadvantages are acceptable trade-offs.

- If your primary focus is high-volume, repetitive stamping: A mechanical press is likely a better fit due to its superior speed.

- If your primary focus is forming, deep drawing, or applications requiring immense, sustained force: The disadvantages of a hydraulic press are often an acceptable trade-off for its unmatched power and control.

- If your primary focus is a clean environment or minimizing energy costs: You should strongly consider an electromechanical or servo press as a modern alternative.

By weighing these inherent disadvantages against its formidable power, you can confidently select the right tool for the job.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Low Operational Speed | Slower cycle times, production bottleneck for high-volume work |

| High Energy Consumption | Pump runs continuously, leading to higher operational costs |

| Potential for Fluid Leaks | Messy workspace, slip hazards, part contamination |

| Significant Maintenance | Regular checks of fluid, filters, seals, and hoses required |

| Flammable Fluids | Introduces a fire hazard, requiring specific safety protocols |

Choosing the right press is critical for your lab's efficiency and safety. The disadvantages of a hydraulic press—like high maintenance and energy costs—might make it unsuitable for your specific application. At KINTEK, we specialize in lab equipment and consumables, helping you navigate these trade-offs to find the perfect press for your needs, whether hydraulic, mechanical, or a modern servo alternative.

Let our experts help you optimize your workflow and control costs. Contact KINTEK today for a personalized consultation!

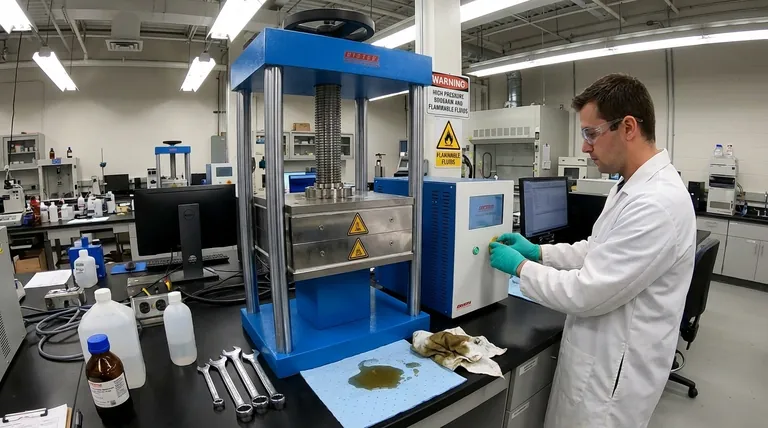

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

People Also Ask

- How is a laboratory hydraulic press utilized in the fabrication of Na3SbS4 pellets? Achieve High-Density Electrolytes

- What metal is used in a hydraulic press? The Critical Role of Steel in High-Force Applications

- Why is a hydraulic press used to apply 380 MPa to battery bilayers? Achieve Superior Density & Safety

- What are the three applications of a hydraulic press? From Metal Forming to Lab Precision

- How do you prepare a sample for fluorescence spectroscopy? A Step-by-Step Guide for Accurate Results

- How do laboratory hydraulic presses ensure solid-state electrolyte performance? Optimize Battery Density & Conductivity

- How do you calculate hydraulic tonnage of a press? Master the Force Formula for Your Lab Press

- How do you prepare KBr pellets for FTIR? Master the Technique for High-Quality IR Analysis