The primary disadvantages of a muffle furnace are its slower heating speed, higher energy consumption, and potential for damage to its internal heating elements. Additionally, conventional designs can be bulky, and the enclosed chamber can make accessing and placing materials more difficult compared to open-heating methods.

The core trade-off of a muffle furnace lies in its fundamental design. The very feature that makes it valuable—an isolated chamber for contamination-free heating—also acts as an thermal barrier, leading to inherent inefficiencies in speed and energy usage.

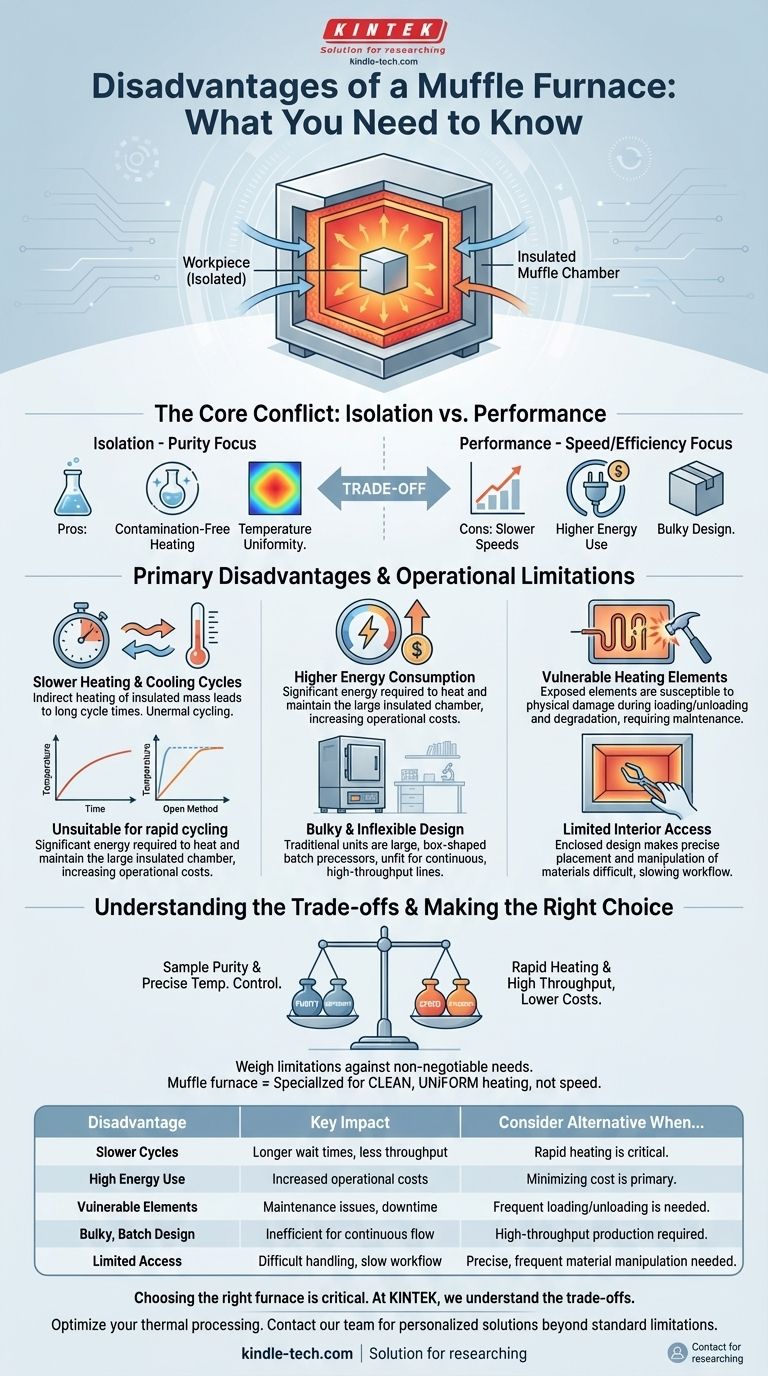

The Core Conflict: Isolation vs. Performance

A muffle furnace's defining characteristic is its "muffle"—an insulated inner chamber that separates the material being heated from the heating elements and any potential contaminants, such as byproducts of combustion in non-electric models. This design is excellent for purity but introduces performance drawbacks.

Slower Heating and Cooling Cycles

The furnace must first heat the entire mass of the insulated muffle chamber before that heat can be effectively transferred to the workpiece inside.

This indirect heating process inherently takes longer to reach the target temperature compared to direct-heating methods like an open flame or induction furnace. This makes it less ideal for applications requiring very quick thermal cycling.

Higher Energy Consumption

Heating the large, insulated thermal mass of the furnace chamber requires a significant amount of energy.

Conventional designs, in particular, are noted for high energy consumption because of the extended time needed to reach and maintain high temperatures. This can translate to higher operational costs, especially in production environments.

Operational and Design Limitations

Beyond thermal performance, the physical design of many muffle furnaces presents practical challenges.

Vulnerable Heating Elements

In many conventional electric designs, the resistance wire heating elements are exposed within the furnace structure.

This exposure can make them susceptible to physical damage during loading and unloading or to degradation over time, leading to maintenance and reliability issues.

Bulky and Inflexible Form Factor

Traditionally, muffle furnaces are bulky, box-shaped units with the control systems housed in a separate module. This can take up considerable lab or floor space.

Their fixed, batch-processing nature (using a single door for loading and unloading) makes them unsuitable for continuous or high-throughput manufacturing lines.

Limited Interior Access

The enclosed, often deep chamber design can make it difficult to precisely place or manipulate materials inside the furnace.

This requires careful handling with tongs or other tools and can slow down the workflow, especially when dealing with multiple small samples.

Understanding the Trade-offs

The disadvantages of a muffle furnace only become critical when misaligned with the application's goals. The choice to use one is a conscious trade-off between purity and performance.

Purity vs. Speed

The muffle furnace's greatest strength is isolating the workpiece from contaminants, ensuring a clean heating process.

If sample purity is your top priority (as in many chemical analyses or specialized material treatments), the slower speed is an acceptable price to pay. If speed is critical and slight contamination is tolerable, other methods may be superior.

Temperature Uniformity vs. Throughput

The enclosed and insulated chamber of a modern muffle furnace provides excellent temperature uniformity, ensuring the entire workpiece is treated homogeneously.

However, this precision comes at the cost of throughput. Its nature as a batch-processing tool with longer cycle times makes it inefficient for applications demanding rapid, continuous production.

Making the Right Choice for Your Application

To determine if a muffle furnace is appropriate, you must weigh its limitations against the non-negotiable requirements of your work.

- If your primary focus is sample purity and precise temperature control: The muffle furnace is likely the correct tool, and its slower performance is a necessary trade-off.

- If your primary focus is rapid heating and high throughput: The slower cycle times and batch-processing nature mean you should investigate alternatives like induction or direct-fire furnaces.

- If your primary focus is minimizing operational costs: You must carefully evaluate the high energy consumption of conventional models against the efficiency of newer designs for your specific use case.

Ultimately, a muffle furnace is a specialized instrument designed for clean, uniform heating in a controlled environment, and its disadvantages are the direct consequence of that specialized design.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Slower Heating/Cooling | Indirect heating leads to longer cycle times, unsuitable for rapid thermal cycling. |

| Higher Energy Consumption | Heating the insulated chamber mass increases operational costs. |

| Vulnerable Heating Elements | Exposed elements can be damaged during loading/unloading, requiring maintenance. |

| Bulky, Batch-Process Design | Takes up significant space and is inefficient for continuous, high-throughput production. |

| Limited Interior Access | Enclosed chamber can make material placement and handling more difficult. |

Choosing the right furnace is critical for your lab's efficiency and budget.

At KINTEK, we specialize in lab equipment and understand that the disadvantages of a standard muffle furnace might not align with your specific needs. Whether you require faster heating, better energy efficiency, or a design suited for high-throughput workflows, our experts can help you find the perfect solution.

Let us help you optimize your thermal processing. Contact our team today for a personalized consultation to discuss your application and find the ideal furnace for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the primary functions of using a high-temperature laboratory furnace for the calcination of zirconium dioxide products?

- What is the function of a high-temperature muffle furnace in the preparation of NbOx-SiO2 catalysts? Transform Precursors

- What is the primary purpose of using high-temperature sintering furnaces for post-processing SLM? Unlock Peak Performance

- What is the temperature range of a laboratory muffle furnace? Find the Right Model for Your Application

- What role does a high-temperature muffle furnace play in the post-processing of metal oxide nanomaterials? Key Insights

- How does a laboratory muffle furnace ensure accuracy in biomass ash determination? Optimize Your Material Analysis

- How does a high-temperature muffle furnace function for ferrotitanium oxide pellets? Optimize Phase Transformation

- How is a high-temperature muffle furnace utilized in the performance evaluation of CrSi coatings?