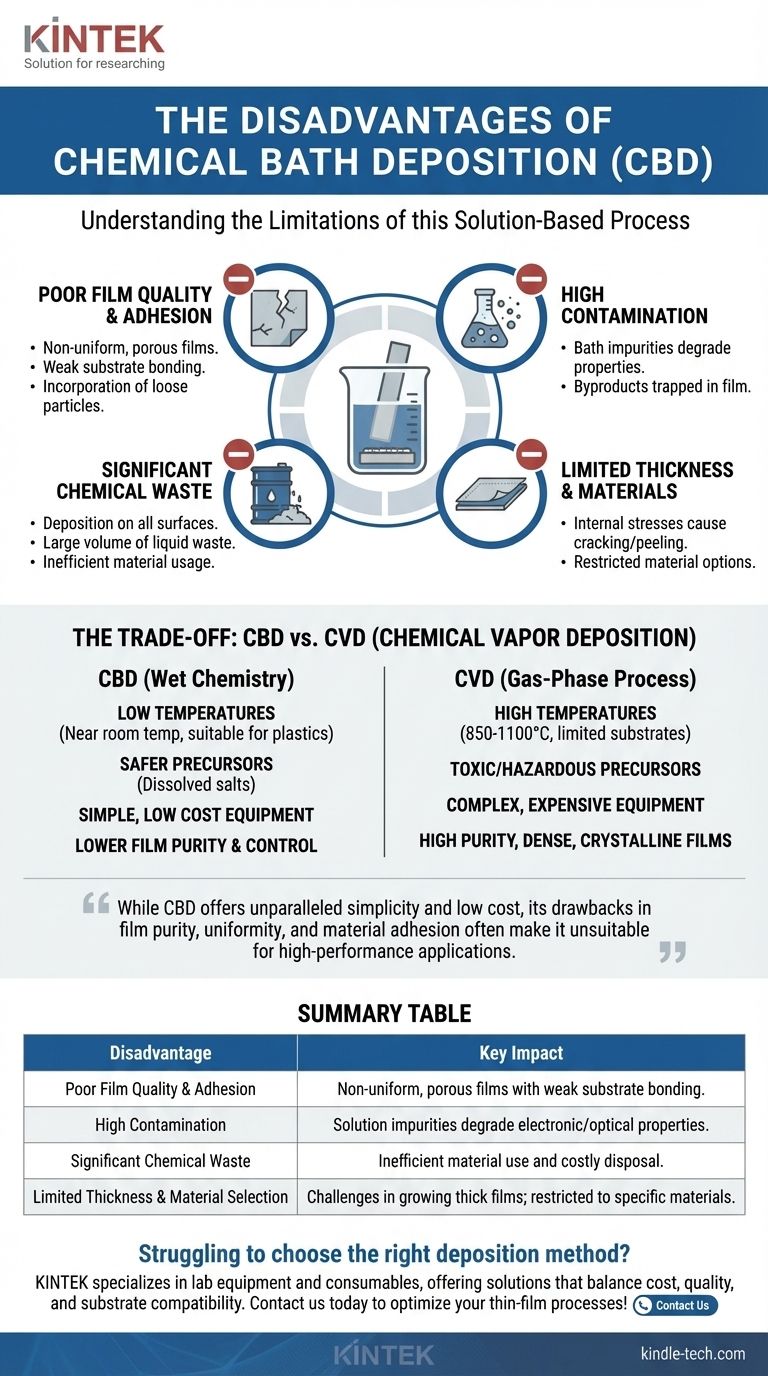

It is critical to distinguish between Chemical Bath Deposition (CBD) and Chemical Vapor Deposition (CVD), as the provided references exclusively discuss the latter. CBD is a solution-based, "wet" chemistry process, while CVD is a gas-phase process. The primary disadvantages of Chemical Bath Deposition (CBD) are poor film quality and adhesion, high levels of contamination from the solution, and significant chemical waste.

While CBD offers unparalleled simplicity and low cost, its drawbacks in film purity, uniformity, and material adhesion often make it unsuitable for high-performance applications, forcing a trade-off between accessibility and quality.

The Core Limitations of Chemical Bath Deposition

Chemical Bath Deposition is a "bottom-up" technique where a substrate is immersed in a liquid solution containing precursor ions. The film forms as these ions react and precipitate onto the substrate surface. While simple, this process introduces several inherent disadvantages.

Film Quality and Adhesion Issues

One of the most significant drawbacks is the resulting film quality. The growth process is often difficult to control precisely, leading to films that can be non-uniform, porous, and poorly adhered to the substrate.

Because deposition occurs throughout the solution, particles also form in the bulk liquid (homogeneous nucleation) and can settle onto the substrate. This incorporation of loose particles disrupts crystal growth and weakens the film's adhesion.

Purity and Contamination Problems

The "bath" itself is a major source of contamination. Any impurities in the precursor chemicals or the solvent (typically water) can easily become incorporated into the growing film, degrading its electronic or optical properties.

Furthermore, byproducts of the chemical reaction remain in the solution and can also be trapped in the film, further reducing its purity and performance.

Inefficient Material Usage and Waste

CBD is an inherently wasteful process. Deposition occurs on all immersed surfaces, including the walls of the beaker and any substrate holders, not just the target substrate.

A significant amount of precursor material is also consumed by a precipitation reaction that forms powders within the solution itself, which are then discarded. This generates a large volume of chemical waste that requires proper and often costly disposal.

Limited Thickness and Material Selection

Achieving thick, high-quality films with CBD is challenging. As the film grows thicker, internal stresses can build up, leading to cracking or peeling. The deposition process also slows and can eventually stop as precursor chemicals are depleted.

While CBD is versatile for certain materials like metal chalcogenides (e.g., CdS, ZnS), it is not suitable for a wide range of materials, particularly elemental metals or complex oxides that require high temperatures or specific atmospheres to form.

Understanding the Trade-offs: CBD vs. CVD

To fully appreciate CBD's limitations, it is useful to contrast it with the gas-phase method of Chemical Vapor Deposition (CVD), which the references describe. They are fundamentally different processes with opposing strengths and weaknesses.

The Problem of Temperature

CVD typically requires very high temperatures (often 850–1100°C) for the chemical reactions to occur. This severely limits the types of substrates that can be used, as many materials cannot withstand such heat without melting, warping, or degrading.

CBD, in contrast, operates at low temperatures, often near room temperature or slightly elevated (e.g., below 100°C). This makes it compatible with a wide variety of substrates, including flexible plastics and inexpensive glass.

The Challenge of Precursors and Byproducts

CVD relies on volatile chemical precursors that must be delivered in a gas phase. These precursors can be highly toxic, flammable, or pyrophoric, posing significant safety risks and requiring complex handling equipment. Its byproducts are also often corrosive and toxic, creating disposal challenges.

CBD uses dissolved chemical salts that are generally safer and easier to handle than their volatile CVD counterparts. However, as noted, it produces a much larger volume of liquid waste.

Film Purity and Control

The controlled, gas-phase environment of CVD allows for the growth of high-purity, dense, and crystalline films with excellent adhesion. By precisely adjusting gas flows and deposition parameters, one can achieve fine control over the film's composition and structure.

CBD's liquid environment makes achieving this level of purity and structural control nearly impossible. It trades quality and precision for operational simplicity and low equipment cost.

Making the Right Choice for Your Application

Choosing a deposition method requires aligning the technique's strengths with your project's final goal.

- If your primary focus is rapid prototyping or low-cost, large-area coating: CBD is an excellent choice, as its low temperature and equipment simplicity are major advantages.

- If your primary focus is high-performance electronic or optical devices: CVD is the superior method, as it delivers the high purity, uniformity, and film quality required for these applications.

- If your primary focus is material compatibility with sensitive substrates: CBD's low-temperature nature makes it one of the few viable options for coating plastics or other temperature-sensitive materials.

Ultimately, your choice depends on a clear understanding of whether your application can tolerate the inherent quality limitations of CBD in exchange for its low barrier to entry.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Poor Film Quality & Adhesion | Non-uniform, porous films with weak substrate bonding. |

| High Contamination | Solution impurities degrade electronic/optical properties. |

| Significant Chemical Waste | Inefficient material use and costly disposal. |

| Limited Thickness & Material Selection | Challenges in growing thick films; restricted to specific materials. |

Struggling to choose the right deposition method for your application? KINTEK specializes in lab equipment and consumables, offering solutions that balance cost, quality, and substrate compatibility. Whether you need the simplicity of CBD or the high performance of CVD, our experts can help you select the ideal setup for your laboratory's unique needs. Contact us today to optimize your thin-film processes!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition