While highly effective, conformal coatings introduce significant challenges in application, rework, and cost that must be carefully managed. The primary disadvantages are the difficulty of applying a defect-free layer, the complexity and risk involved in removing the coating for repair, and the potential for the coating itself to create thermal stress on components and solder joints.

The crucial takeaway is that conformal coating is not a simple final step, but a complex sub-process in manufacturing. Its protective benefits are undeniable, but they come at the cost of increased process control, specialized labor, and potential new failure modes if not executed perfectly.

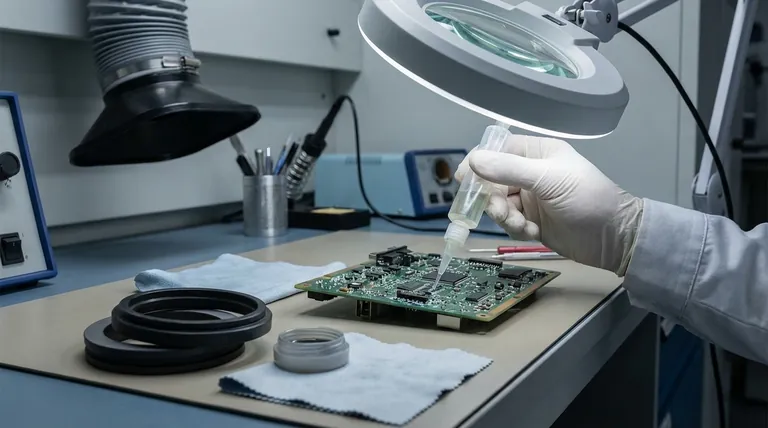

Process and Application Challenges

Applying conformal coating is a precision task where small errors can lead to significant reliability problems. The goal of a perfectly uniform, thin layer is difficult to achieve in practice.

The Intricacies of Application

The coating must be applied at a specific, consistent thickness. Too thin, and it offers inadequate protection. Too thick, and it can shrink during curing, creating mechanical stress on components.

Achieving this consistency requires either highly skilled manual spraying or significant capital investment in automated selective coating systems.

The Masking Requirement

Connectors, test points, and certain components cannot be coated. This necessitates a labor-intensive process called masking, where these areas are manually covered before coating and uncovered afterward.

Masking is a common source of error. Improperly applied masks can lead to coating leaks (contaminating a connector) or "shadowing" (leaving nearby areas uncoated).

The Risk of Coating Defects

Several types of defects can occur during application and curing. Bubbles can form from trapped solvents or air, creating voids in the protective layer. Delamination (peeling) can occur if the board surface is not perfectly clean.

Other issues like crazing (micro-fractures) and improper curing can compromise the coating's integrity, turning a protective layer into a liability that traps moisture instead of repelling it.

Rework and Repair Complications

Perhaps the most significant operational disadvantage is the extreme difficulty of repairing a coated board. The very properties that make a coating a good protectant also make it a formidable barrier.

The Challenge of Removal

Conformal coatings are designed to be durable and chemically resistant. By definition, they are not meant to be easily removed. Removing a coating to replace a single failed component is often more difficult than the repair itself.

Methods and Their Downsides

There is no single perfect removal method. Chemical stripping uses harsh solvents that can damage sensitive components and plastic housings. Thermal removal involves using a soldering iron to burn through the coating, which creates toxic fumes and can damage the board.

Abrasive methods, like micro-blasting, are effective but risk damaging the PCB laminate and nearby components through electrostatic discharge (ESD) or physical impact.

Performance and Reliability Trade-offs

While intended to improve reliability, the coating itself can introduce new failure mechanisms if not chosen and applied correctly.

Thermal Stress and CTE Mismatch

Every material expands and contracts with temperature changes at a different rate, known as its Coefficient of Thermal Expansion (CTE). A hard coating (like epoxy or urethane) with a different CTE than the PCB can exert immense stress on solder joints during thermal cycling.

This mismatch can lead to premature solder joint fatigue and failure, a problem the coating was intended to prevent.

Potential for Trapping Contaminants

Conformal coating is only effective if applied to a perfectly clean and dry surface. If any ionic contaminants (like flux residue) or moisture are present on the board before coating, the coating will seal them in.

This creates a localized corrosion cell, accelerating failure by trapping the destructive elements directly against the circuitry.

The Economic and Logistical Costs

The decision to use conformal coating has direct and indirect financial implications that extend beyond the cost of the material.

Direct Material and Equipment Costs

The coating chemicals themselves can be expensive, particularly specialized materials like Parylene. Furthermore, proper application requires investment in spray booths, curing ovens, and sophisticated inspection systems (like UV lights and automated optical inspection).

Indirect Labor and Training Costs

The processes of masking, de-masking, application, and inspection are all labor-intensive. Technicians require specific training to perform these tasks correctly and safely, especially when handling volatile chemicals.

Impact on Production Cycle Time

Conformal coating adds multiple steps and significant time to the manufacturing process. Application, flash-off (allowing solvents to evaporate), and curing can add hours or even days to the production cycle for a single assembly, impacting overall throughput.

Making the Right Choice for Your Goal

Evaluating these disadvantages against your product's specific requirements is critical for making a sound engineering decision.

- If your primary focus is maximum reliability in harsh environments (aerospace, military): Accept the high cost and complexity as necessary, but invest heavily in process control, operator training, and rigorous board cleaning protocols.

- If your primary focus is high-volume, cost-sensitive production (consumer electronics): Scrutinize whether coating is truly necessary. Consider designing a more protective enclosure or using selective coating on only the most vulnerable areas to minimize cost and complexity.

- If your primary focus is serviceability and repair (industrial equipment): Choose a softer, more easily removable coating like an acrylic or silicone, and ensure your service depots are equipped with the proper, documented procedures and tools for safe removal and reapplication.

Understanding these trade-offs transforms conformal coating from a potential liability into a powerful and predictable tool for enhancing electronic reliability.

Summary Table:

| Disadvantage Category | Key Challenges |

|---|---|

| Process & Application | Defect-prone application, masking requirements, inconsistent thickness |

| Rework & Repair | Difficult coating removal, risk of board damage, toxic fumes |

| Performance & Reliability | CTE mismatch stress, potential for trapping contaminants |

| Economic & Logistical | High material/equipment costs, labor-intensive steps, longer cycle times |

Struggling with conformal coating challenges in your lab? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision tools for PCB protection and reliability testing. Our experts can help you select the right coating application systems, streamline rework processes, and avoid costly defects—ensuring your electronic assemblies meet stringent quality standards. Contact us today to optimize your conformal coating workflow and enhance product durability!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

People Also Ask

- Is diamond coating worth it? Maximize Component Life and Performance

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer