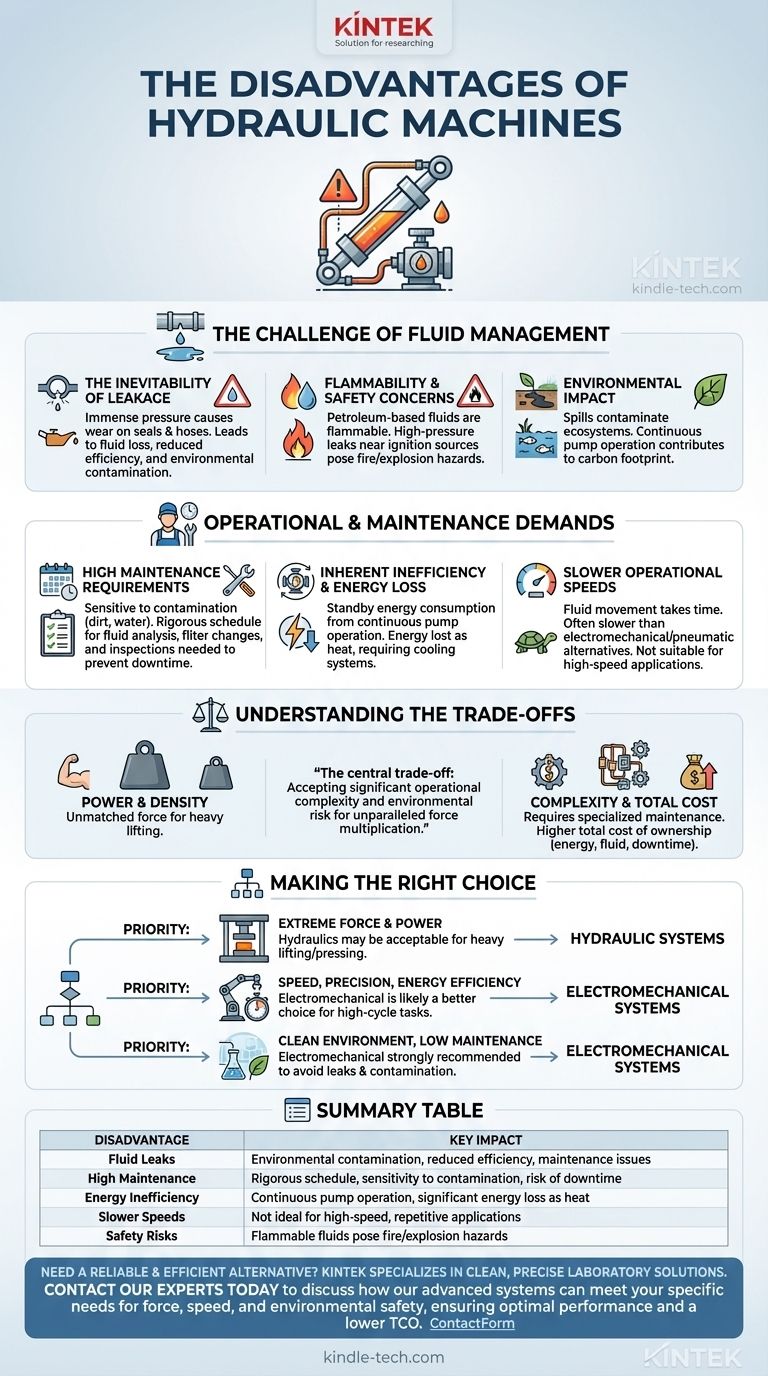

At their core, the disadvantages of hydraulic machines stem from the very fluid that gives them power. Key drawbacks include the potential for fluid leaks, high maintenance requirements, operational inefficiency, slower speeds, and safety risks associated with flammable fluids. These factors create a higher total cost of ownership than may be apparent at first.

The central trade-off of hydraulics is accepting significant operational complexity and potential environmental risk in exchange for unparalleled force multiplication and power density.

The Challenge of Managing Hydraulic Fluid

The defining component of a hydraulic system—its fluid—is also the source of its most significant challenges. Proper management is critical for performance and safety.

The Inevitability of Leakage

Hydraulic systems operate under immense pressure, which puts constant stress on seals, hoses, and fittings. Over time, these components wear out, making fluid leaks a common point of failure.

These leaks are not just a maintenance nuisance; they lead to fluid loss, reduced system efficiency, and potential environmental contamination.

Flammability and Safety Concerns

Many standard hydraulic fluids are petroleum-based and therefore flammable.

If a high-pressure leak atomizes this fluid into a fine mist near an ignition source, it can create a serious fire or explosion hazard, making it unsuitable for certain high-temperature environments without specialized, more expensive fluids.

Environmental Impact

The environmental footprint of hydraulics is twofold. Spilled or leaked hydraulic oil can contaminate soil and water, posing a risk to ecosystems.

Furthermore, the energy required to run the hydraulic pump, often continuously, contributes to the system's overall carbon footprint.

Operational and Maintenance Demands

Beyond fluid management, hydraulic systems present distinct operational challenges that impact efficiency, speed, and long-term cost.

High Maintenance Requirements

Hydraulic systems are sensitive to contamination. Dirt, water, or even air in the fluid can damage precision components like pumps and valves, leading to premature failure.

This sensitivity necessitates a rigorous maintenance schedule, including regular fluid analysis, filter changes, and inspection of seals and hoses to prevent costly downtime.

Inherent Inefficiency and Energy Loss

Most hydraulic systems run a pump continuously to maintain pressure, even when no work is being done. This standby energy consumption is a significant source of inefficiency.

Energy is also lost as heat when the fluid is forced through pipes, valves, and orifices, often requiring large reservoirs or dedicated coolers to dissipate it.

Slower Operational Speeds

The movement of fluid to actuate a cylinder or motor takes time. Consequently, hydraulic machines are often slower than their electromechanical or pneumatic counterparts.

This makes them less suitable for high-speed, repetitive applications where cycle time is a critical factor.

Understanding the Trade-offs

Choosing a hydraulic system means understanding its inherent compromises. The immense power it offers comes with specific costs that must be weighed against your application's needs.

Power vs. Complexity

Hydraulics are unmatched in their ability to generate massive amounts of force from compact components. This is their primary advantage.

However, this power comes with the complexity of managing a fluid system, including pumps, reservoirs, filters, valves, and heat exchangers, all of which require specialized knowledge to maintain.

Initial Cost vs. Total Cost of Ownership

While the initial components for a hydraulic system can be cost-effective, the total cost of ownership is often higher.

Factors like continuous energy consumption, ongoing maintenance, the cost of hydraulic fluid, and potential cleanup expenses must be factored into any long-term financial analysis.

Making the Right Choice for Your Application

The decision to use a hydraulic system must be based on a clear-eyed assessment of its strengths and weaknesses relative to your specific goal.

- If your primary focus is extreme force and power density: The disadvantages are often acceptable trade-offs, as few technologies can match the raw power of hydraulics for heavy lifting and pressing.

- If your primary focus is speed, precision, and energy efficiency: An electromechanical system is almost always a better choice for high-cycle, automated tasks.

- If your primary focus is a clean environment or low maintenance: You should strongly consider electromechanical alternatives to avoid the risks of fluid leaks and contamination.

Ultimately, selecting the right technology requires balancing the need for immense power against the demands of operational cleanliness, efficiency, and maintenance.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Fluid Leaks | Environmental contamination, reduced efficiency, maintenance issues |

| High Maintenance | Rigorous schedule, sensitivity to contamination, risk of downtime |

| Energy Inefficiency | Continuous pump operation, significant energy loss as heat |

| Slower Speeds | Not ideal for high-speed, repetitive applications |

| Safety Risks | Flammable fluids pose fire/explosion hazards in certain environments |

Need a reliable and efficient alternative for your laboratory applications?

While hydraulic systems have their place, many modern labs require cleaner, more precise, and energy-efficient solutions. KINTEK specializes in high-performance lab equipment and consumables designed for accuracy, safety, and low maintenance.

Contact our experts today to discuss how our electromechanical and other advanced systems can meet your specific force, speed, and environmental requirements, ensuring optimal performance and a lower total cost of ownership for your laboratory.

Visual Guide

Related Products

- Manual Lab Heat Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- What is the conclusion of a hydraulic press? Unmatched Force for Industrial Applications

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab