The primary disadvantages of an induction furnace are its lack of metallurgical refining capability, operational inflexibility for certain production schedules, and high dependence on the quality of the raw materials being charged. Because heat is generated directly within the metal, there is no secondary heat source to effectively remove impurities via slag, making the quality of the output entirely dependent on the quality of the input.

While prized for its precision, cleanliness, and efficiency, an induction furnace is fundamentally a re-melting device, not a refining one. Its main drawbacks stem from this limitation and the operational constraints it imposes, particularly for continuous or large-scale operations.

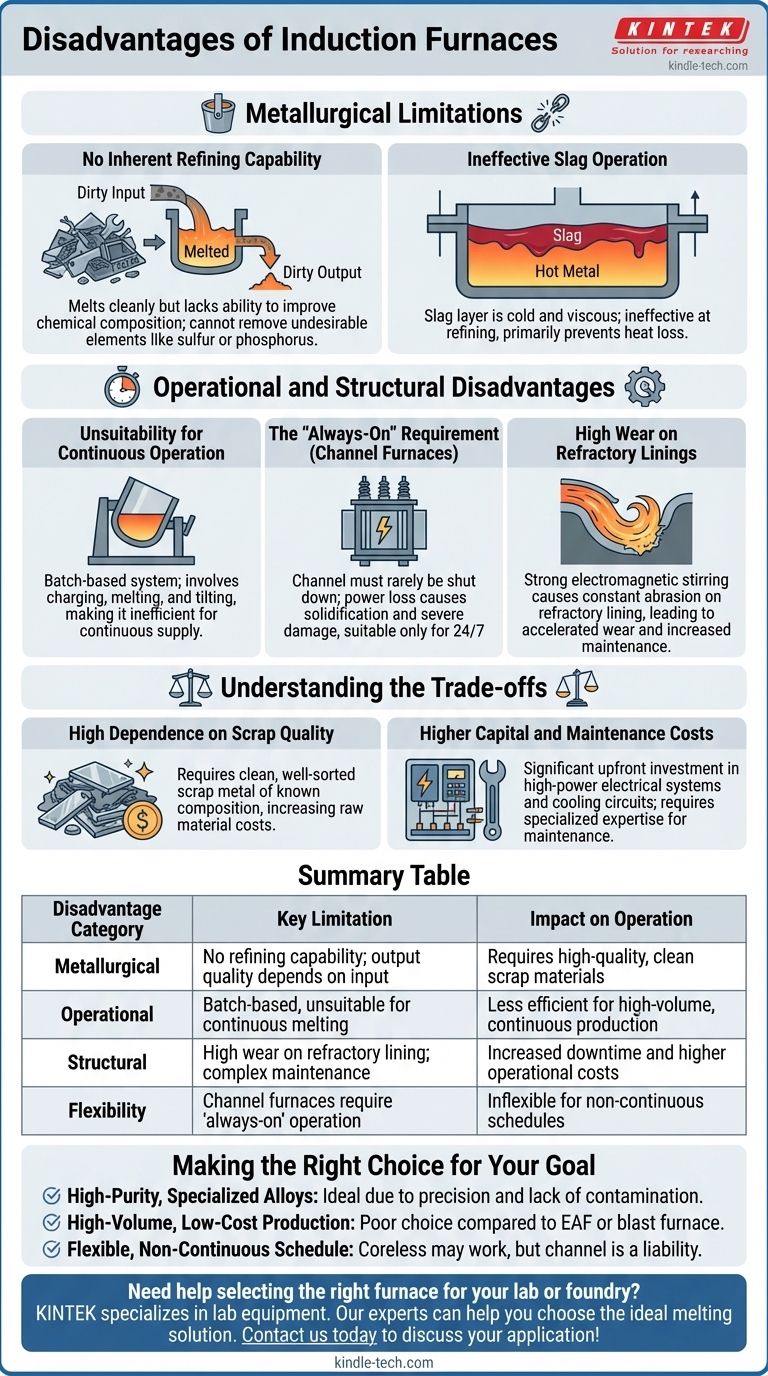

The Metallurgical Limitations

The core principle of induction heating—generating heat within the charge itself—is both its greatest strength and the source of its key weakness. It melts material cleanly but offers almost no ability to improve its chemical composition.

No Inherent Refining Capability

An induction furnace simply melts the charge material. Unlike an Electric Arc Furnace (EAF), it lacks the high-intensity arc and chemical reactions needed to remove undesirable elements like sulfur and phosphorus.

The final product's chemical makeup will be nearly identical to that of the scrap and alloys you put in. This means you cannot use it to upgrade low-quality, contaminated scrap into high-quality metal.

Ineffective Slag Operation

In other furnace types, a layer of molten slag on top of the metal is superheated, allowing it to absorb impurities. In an induction furnace, the metal is hotter than the slag.

This results in a relatively cold and viscous slag layer that is ineffective at refining. Its primary function is simply to prevent heat loss and oxidation, not to clean the metal.

Operational and Structural Disadvantages

Beyond metallurgy, induction furnaces present several operational challenges that can make them unsuitable for certain types of foundries or production schedules.

Unsuitability for Continuous Operation

Most induction furnaces are batch-based systems. The process involves charging the furnace, melting the material, and then tilting the entire vessel to pour the metal into a ladle or mould.

This cycle of charging and tilting makes it less efficient for applications that require a continuous, uninterrupted supply of molten metal.

The "Always-On" Requirement for Channel Furnaces

A specific type, the channel induction furnace, operates like a transformer where a loop of molten metal acts as the secondary coil. This design is highly efficient but comes with a major drawback.

The furnace can rarely be shut down. If power is lost or the furnace is turned off, the metal in the channel will solidify, which can severely damage the refractory lining and require a very costly and time-consuming restart. This makes them suitable only for 24/7 operations.

High Wear on Refractory Linings

The electromagnetic field that heats the metal also creates a strong stirring action. While this is excellent for creating a homogenous, evenly mixed alloy, it also causes constant movement of the molten metal against the furnace's refractory lining.

This continuous abrasive action can lead to accelerated wear and tear on the lining, increasing maintenance costs and requiring more frequent downtime for repairs.

Understanding the Trade-offs

Choosing an induction furnace involves accepting a clear set of compromises. Its precision and cleanliness come at the cost of flexibility and refining power.

High Dependence on Scrap Quality

The inability to refine material means the entire business model for an induction furnace foundry relies on sourcing clean, well-sorted scrap metal of a known composition.

This can significantly increase raw material costs compared to operations that can use cheaper, lower-grade scrap and refine it in the furnace.

Higher Capital and Maintenance Costs

The high-power electrical systems, including power supplies, capacitor banks, and heavy-duty water-cooling circuits, represent a significant upfront investment.

Furthermore, maintaining these complex electrical systems and managing the regular replacement of refractory linings requires specialized expertise and adds to the ongoing operational budget.

Making the Right Choice for Your Goal

Ultimately, the disadvantages of an induction furnace are only disadvantages if they conflict with your specific production requirements.

- If your primary focus is producing high-purity, specialized alloys from clean inputs: The precision and lack of contamination are ideal, making the trade-offs acceptable.

- If your primary focus is high-volume, low-cost steel or iron production: The batch nature and inability to refine low-grade scrap make an induction furnace a poor choice compared to an EAF or blast furnace.

- If your primary focus is operating a flexible, non-continuous schedule: A coreless induction furnace may work, but a channel furnace's "always-on" requirement is a significant liability.

Choosing the right furnace technology requires a clear understanding of not just what it does well, but also what it fundamentally cannot do.

Summary Table:

| Disadvantage Category | Key Limitation | Impact on Operation |

|---|---|---|

| Metallurgical | No refining capability; output quality depends on input | Requires high-quality, clean scrap materials |

| Operational | Batch-based, unsuitable for continuous melting | Less efficient for high-volume, continuous production |

| Structural | High wear on refractory lining; complex maintenance | Increased downtime and higher operational costs |

| Flexibility | Channel furnaces require 'always-on' operation | Inflexible for non-continuous schedules |

Need help selecting the right furnace for your lab or foundry? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you choose the ideal melting solution based on your specific production goals and material requirements. Contact us today to discuss your application and ensure you get the performance you need!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What materials can be heated with induction? A Guide to Efficient Metal Heating

- What is the frequency range of an induction furnace? Unlock the Key to Efficient Metal Melting

- How does a high vacuum induction melting furnace optimize FATT50? Enhancing Metal Toughness and Purity

- What is the frequency of induction melting furnace? Optimize Your Melting Process with the Right Frequency

- What is a furnace used in melting non-ferrous metals? Choose Between Induction & Fuel-Fired

- How does an induction heating treatment chamber optimize molybdenum alloy tubes? Achieve Superior Material Integrity

- What is the purpose of an induction furnace? Achieve Clean, Efficient Metal Melting

- How does an induction heating furnace work? Discover the Power of Internal, Contactless Heating