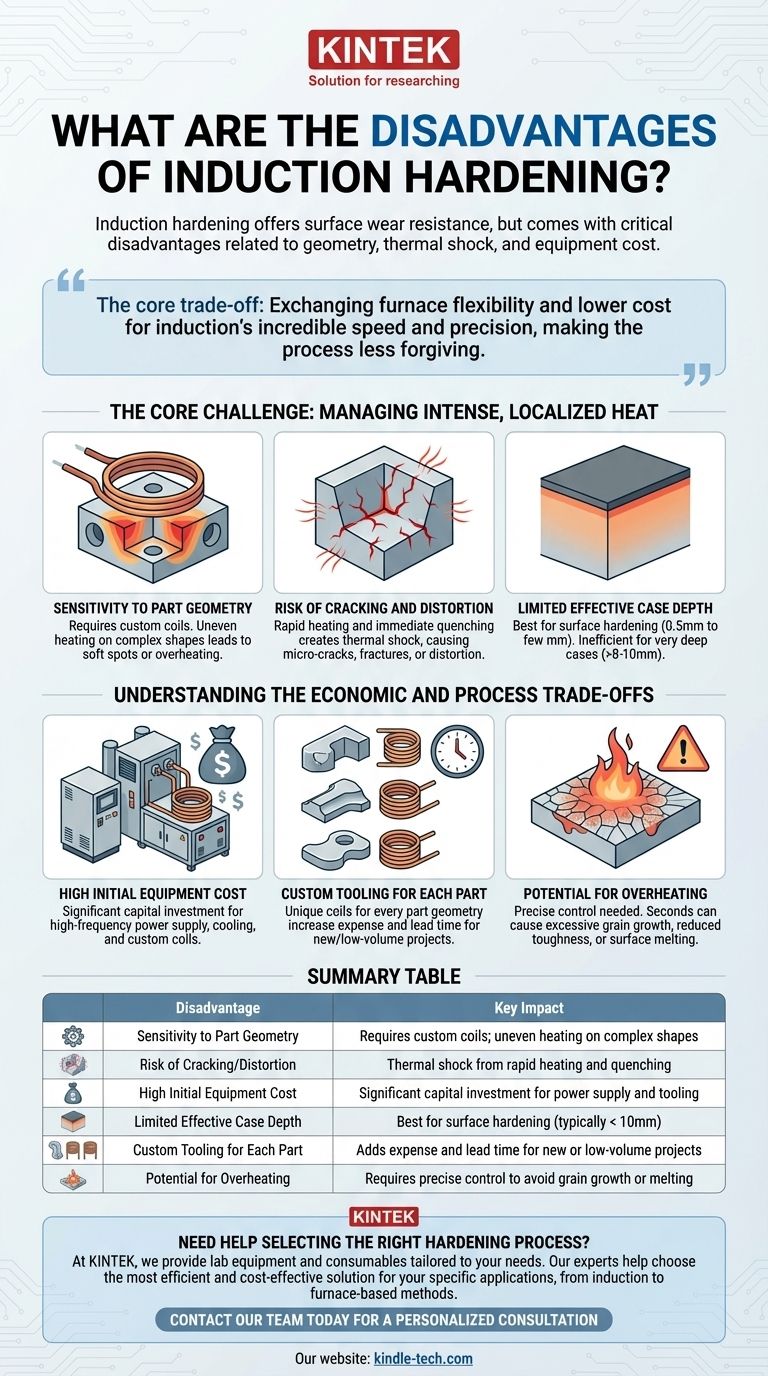

While induction hardening is a highly effective method for increasing surface wear resistance, it is not a universal solution and presents several critical disadvantages. The primary drawbacks stem from its sensitivity to part geometry, the inherent risk of cracking or distortion due to thermal shock, and the significant initial investment required for specialized equipment.

The core trade-off of induction hardening is exchanging the flexibility and lower equipment cost of furnace-based methods for incredible speed and precision. This exchange, however, makes the process less forgiving and more dependent on part geometry and material composition.

The Core Challenge: Managing Intense, Localized Heat

Induction hardening's primary advantage—its ability to deliver rapid, localized heat—is also the source of its main technical challenges. The entire process hinges on carefully managing this intense thermal cycle.

Sensitivity to Part Geometry

The induction coil, which generates the heating electromagnetic field, must closely match the shape of the part being hardened. A uniform gap between the coil and the part surface is essential for even heating.

For parts with complex shapes, sharp corners, holes, or keyways, designing an effective coil is difficult and expensive. Uneven heating in these areas can lead to soft spots or localized overheating.

Risk of Cracking and Distortion

The process involves extremely rapid heating followed by immediate quenching. This creates a massive thermal shock in the material.

If a part has sharp internal corners or drastic changes in thickness, this thermal stress can cause micro-cracks or even full-blown fracture. Thin sections may warp or distort under this rapid cycle.

Limited Effective Case Depth

Induction hardening is fundamentally a surface-hardening process. It excels at creating a hard case from 0.5mm to a few millimeters deep.

Achieving very deep case depths (e.g., over 8-10mm) is inefficient and can be more effectively accomplished with through-hardening or other methods like carburizing, which allow carbon to diffuse deep into the part over time.

Understanding the Economic and Process Trade-offs

Beyond the technical physics, the practical and economic realities of induction hardening are crucial factors in any decision.

High Initial Equipment Cost

Induction hardening systems, which include a high-frequency power supply, cooling systems, and custom coils, represent a significant capital investment. This cost is often much higher than that of a conventional hardening furnace.

This makes the process better suited for high-volume production where the cost per part can be justified over a long run.

Custom Tooling for Each Part

A new induction coil must be designed, manufactured, and tested for nearly every unique part geometry. This "tooling" cost adds to the expense and lead time for new projects or low-volume runs.

In contrast, furnace-based treatments can typically handle a wide variety of part shapes simultaneously with no custom tooling required.

Potential for Overheating

The heating rate is measured in seconds. Without precise control of power and time, it is very easy to overheat the surface of the part.

Overheating can lead to excessive grain growth, which reduces the material's toughness and impact resistance, or even cause surface melting. This requires sophisticated process controls and skilled operators to prevent.

Making the Right Choice for Your Application

Choosing the correct hardening process requires aligning the method's strengths and weaknesses with your primary goal.

- If your primary focus is high-volume production of simple, symmetrical parts (like shafts, gears, or pins): Induction hardening is often the most cost-effective and efficient choice due to its speed and repeatability.

- If your primary focus is treating parts with highly complex geometries or in low volumes: Consider furnace hardening or nitriding, which are far less sensitive to part shape and have lower initial tooling costs.

- If your primary focus is achieving a very deep hardened case on low-carbon steel: Carburizing is the superior method, as it chemically alters the surface to allow for deep and uniform hardening.

Ultimately, understanding these limitations is the key to leveraging induction hardening's power effectively without encountering costly failures.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Sensitivity to Part Geometry | Requires custom coils; uneven heating on complex shapes |

| Risk of Cracking/Distortion | Thermal shock from rapid heating and quenching |

| High Initial Equipment Cost | Significant capital investment for power supply and tooling |

| Limited Effective Case Depth | Best for surface hardening (typically < 10mm) |

| Custom Tooling for Each Part | Adds expense and lead time for new or low-volume projects |

| Potential for Overheating | Requires precise control to avoid grain growth or melting |

Need help selecting the right hardening process for your lab or production line?

At KINTEK, we specialize in providing lab equipment and consumables tailored to your specific needs. Whether you're working with high-volume symmetrical parts or complex geometries, our experts can help you choose the most efficient and cost-effective solution—from induction hardening systems to furnace-based alternatives.

Let us enhance your material processing capabilities. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Small Injection Molding Machine for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is the efficiency of an induction furnace? Achieve 75-95% Energy Savings with Direct Heating

- What is the function of an induction melting furnace in titanium recovery from red mud? High-Heat Separation Guide

- What is the function of a vacuum induction arc furnace in AFA steel? Optimize Your High-Performance Alloy Synthesis

- What is the role of a high-frequency induction melting furnace in ZrCu alloy synthesis? Achieve Maximum Purity

- What materials can be used for induction heating? A Guide to Efficient and Effective Material Selection

- Why is high-purity argon gas essential as a shielding gas during the arc melting of Ti-6Al-4V alloy?

- Does induction heating work on graphite? Achieve High-Temperature Precision and Efficiency

- What is the water quality for induction furnace? Ensure Safe, Efficient Melting with the Right Coolant