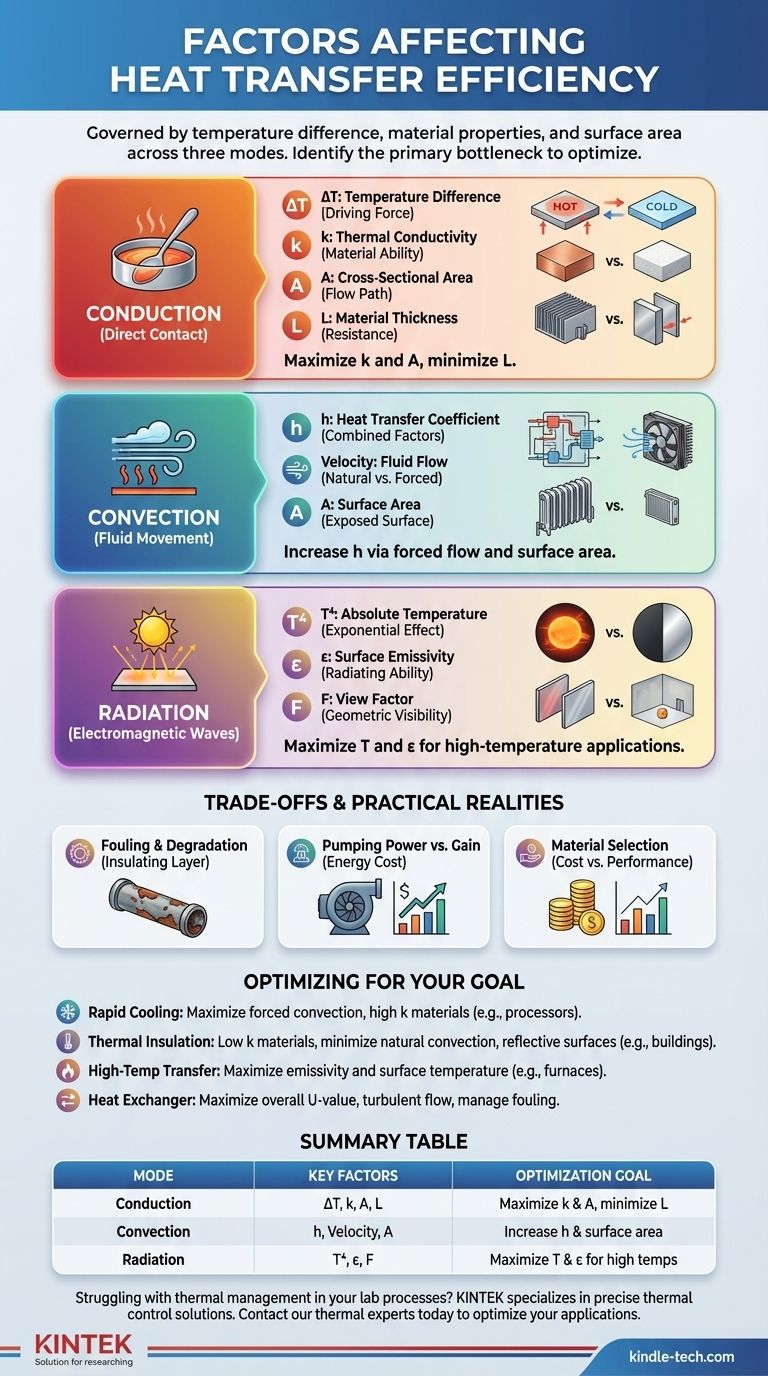

In short, heat transfer efficiency is governed by the temperature difference between objects, the physical properties of the materials involved, and the surface area available for the transfer. These factors manifest differently across the three modes of heat transfer: conduction, convection, and radiation. Understanding which mode is dominant in your system is the first step to optimizing its performance.

The core principle of improving heat transfer is not just about changing one variable, but about identifying the primary bottleneck in your system. Efficiency gains come from systematically addressing the weakest link, whether it's poor material conductivity, slow fluid flow, or an unsuitable surface finish.

The Three Modes of Heat Transfer

Heat transfer is the movement of thermal energy from a hotter area to a colder one. This process occurs through three distinct mechanisms. In nearly all real-world applications, more than one of these modes is present, but one is typically dominant.

Conduction: Transfer Through Direct Contact

Conduction is the transfer of heat through a substance without any movement of the material itself. Think of a metal spoon heating up in a hot cup of coffee.

Convection: Transfer Through Fluid Movement

Convection moves heat using a fluid, like air or water. The fluid heats up, moves to a colder area, and transfers its heat. This is how a furnace heats a house.

Radiation: Transfer Through Electromagnetic Waves

Radiation transfers heat through electromagnetic waves (specifically infrared) and requires no medium. This is how the sun warms the Earth or a fire warms your face.

Key Factors in Conduction

Conduction is governed by a clear relationship known as Fourier's Law. Optimizing it involves manipulating four key variables.

Temperature Difference (ΔT)

This is the primary driving force for heat transfer. The larger the temperature difference between the hot side and the cold side, the faster heat will move.

Material's Thermal Conductivity (k)

Thermal conductivity (k) is a material's intrinsic ability to conduct heat. Metals like copper and aluminum have high 'k' values, making them excellent for heat sinks. Insulators like foam or fiberglass have very low 'k' values, making them ideal for preventing heat transfer.

Cross-Sectional Area (A)

This is the area through which the heat is traveling. A larger area provides more pathways for heat to flow, increasing the overall transfer rate. This is why heat sinks have so many fins—to maximize surface area.

Material Thickness (L)

The thickness of the material, or the length of the path the heat must travel, directly resists heat flow. A thicker wall will insulate better than a thin one made of the same material.

Key Factors in Convection

Convection is more complex as it involves fluid dynamics. The goal is to efficiently move a heated fluid away from a surface.

The Heat Transfer Coefficient (h)

This single value combines many complex factors, including fluid properties (density, viscosity), flow velocity, and surface geometry. A higher heat transfer coefficient (h) means more efficient heat transfer.

Fluid Flow (Velocity)

Convection can be natural (warm, less-dense air rising) or forced (using a fan or pump). Forced convection dramatically increases the heat transfer coefficient by constantly replacing heated fluid at the surface with cooler fluid.

Surface Area (A)

Just as with conduction, a larger surface area exposed to the fluid allows for a higher rate of heat transfer. This is another reason heat sinks use fins—to increase the area for convection to occur.

Key Factors in Radiation

Radiation becomes the dominant mode of heat transfer at very high temperatures or in a vacuum.

Absolute Temperature (T⁴)

The rate of heat transfer by radiation is proportional to the absolute temperature of the surface raised to the fourth power (T⁴). This means that even a small increase in temperature can cause a massive increase in radiated heat.

Surface Emissivity (ε)

Emissivity is a measure of a surface's ability to radiate thermal energy, with a value between 0 and 1. A matte black surface has an emissivity close to 1 (a near-perfect radiator), while a shiny, polished surface has an emissivity close to 0 (a poor radiator).

View Factor (F)

This geometric factor describes how well two surfaces "see" each other. A small object in a large room has a high view factor to its surroundings, while two closely spaced parallel plates have a view factor approaching 1 between them.

Understanding the Trade-offs and Practical Realities

In the real world, theoretical maximums are constrained by practical and economic factors.

Fouling and Surface Degradation

Over time, surfaces in heat exchangers can accumulate dirt, scale, or other deposits. This fouling adds an insulating layer that dramatically reduces the heat transfer coefficient and overall efficiency.

Pumping Power vs. Convective Gain

Increasing fluid velocity with a larger pump or fan boosts forced convection, but it also significantly increases energy consumption and operating cost. There is a point of diminishing returns where the cost of pumping outweighs the benefit of faster heat transfer.

Material Selection: Cost vs. Performance

Copper is a better conductor than aluminum, but it is also heavier and more expensive. The optimal choice depends on the application's budget, weight, and performance requirements.

Dominant vs. Minor Modes

It's critical to identify the dominant mode of heat transfer in your system. For example, spending money to polish a surface (reducing radiation) is useless if 95% of the heat is being removed by forced convection.

Optimizing for Your Specific Goal

The right strategy depends entirely on what you are trying to achieve.

- If your primary focus is rapid cooling (e.g., computer processors): Prioritize maximizing forced convection with high-speed fans or liquid pumps and ensure excellent conduction from the source to the heat sink using thermal paste.

- If your primary focus is thermal insulation (e.g., a building or a thermos): Use materials with low thermal conductivity (k), design to minimize natural convection by trapping air in small pockets, and use reflective surfaces to reduce radiative heat loss.

- If your primary focus is high-temperature transfer (e.g., a furnace): Radiation is dominant, so focus on using high-emissivity materials and maximizing the surface temperature.

- If your primary focus is designing a heat exchanger: The goal is to maximize the overall heat transfer coefficient (U-value) by increasing surface area, promoting turbulent flow, and selecting materials that balance conductivity and cost, while actively managing fouling.

By understanding these fundamental factors, you can move from guessing to making intentional design choices that solve your specific thermal challenge.

Summary Table:

| Mode of Heat Transfer | Key Factors | Optimization Goal |

|---|---|---|

| Conduction | Temperature Difference (ΔT), Thermal Conductivity (k), Cross-Sectional Area (A), Thickness (L) | Maximize k and A, minimize L |

| Convection | Heat Transfer Coefficient (h), Fluid Velocity, Surface Area (A) | Increase h via forced flow and surface area |

| Radiation | Absolute Temperature (T⁴), Surface Emissivity (ε), View Factor (F) | Maximize T and ε for high-temperature applications |

Struggling with thermal management in your lab processes? KINTEK specializes in providing high-performance lab equipment and consumables designed for precise thermal control. Whether you need efficient furnaces, custom heat exchangers, or expert advice on material selection, our solutions are tailored to enhance your laboratory's efficiency and reliability.

Contact our thermal experts today to discuss how we can help you optimize your heat transfer applications.

Visual Guide

Related Products

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Laboratory High Pressure Vacuum Tube Furnace

- 10L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- What is the process of sintering bonding? A Step-by-Step Guide to Solid-State Joining

- What are the sources of materials for biochar production? From Wood to Waste, Choose the Right Feedstock

- Can ceramic be sintered? Discover the Process That Creates Ultra-Durable Materials

- What is an indirect arc furnace? Master Precise, Clean Metal Melting

- How can labs ensure their ULT freezers perform optimally over time? A Guide to Proactive Maintenance

- What are the four types of biomass that can be converted? A Guide to Renewable Energy Sources

- What is the difference between fusion and sintering? Master Material Joining Methods

- Does water bath evaporate? Yes, and here’s how to control it effectively.